Chapter 3 Troubleshooting

24

Anoxomat

®

III Service Guide

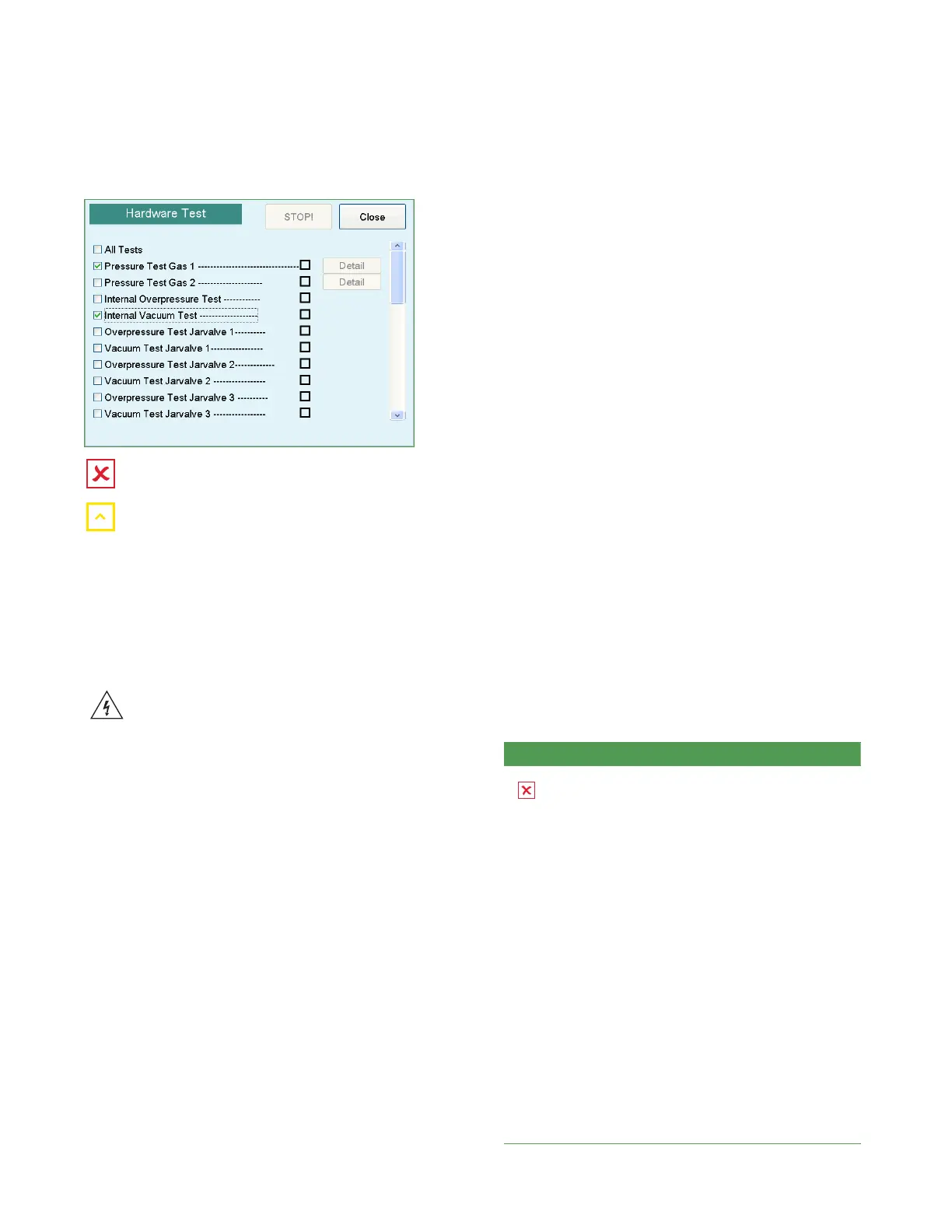

Appears if a jar connection is not used or cannot

be used.

Appears if vacuum is detected in the jar.

WARNING: Some troubleshooting may require

the instrument to be turned on while the cover

is removed. Use extreme caution when

operating the instrument without the cover.

Hazardous voltages are present at the AC

input and the power supply. Only a qualified

service technician should perform these

procedures. The troubleshooting chart in this

section lists problems that may occur while

operating the instrument. The left column

describes the symptom, the middle column

lists checks to determine what is causing the

problem and the right column suggests an

action to resolve the problem. Follow the

checks in the order that they are listed. If you

perform checks out of order, you risk replacing

the wrong part.

3.7 Fuse replacement

If your instrument is not functioning because of blown

fuses, you need to replace the fuses:

1. Switch the power switch to the o position and

disconnect the power cord.

2. Open the door covering the fuses.

3. Check continuity of each fuse with a digital multimeter.

4. Replace fuses that show open circuit.

5. Close fuse door, attach power cord and switch

power on.

3.8 Catalyst errors

After the jar passes the Leak test, during the first cycle

of an anaerobic recipe, the jar is partially filled with the

anaerobic mixture to test if catalyst activity is detected

within the jar. If the pressure inside the jar drops by a

certain amount within the alloted time, then the catalyst

is functional.

The catalyst requires both H and O to work.

A catalyst error message appears if the pressure does

not drop by the specified amount within the expected

time limit. The possible causes of a catalyst error are as

follows:

• No catalyst is in the jar.

• A small sachet are used in a large jar.

• The catalyst has not been properly regenerated

– If the oven temperature drops below 150 °C, the

regeneration time will be increased.

– If the temperature rises above 175 °C°, the palladium

in the catalyst will stop functioning properly due to

heat damage.

• The number of disposable sachets being used is less

than the recommended quantity.

• Re-using a disposable sachet for cycling and

incubation.

Error Possible cause/Suggested action

Jar has not

passed the

corresponding

test. There

isn’t enough

activity to

achieve and

maintain an

anaerobic

atmosphere in

the jar

Cause: No catalyst in the jar:

Action: Insert catalyst in the

appropriate location and restart the

recipe

Cause: Catalyst not generated.

Action: Exchange the catalyst and

restart the recipe (see Operating the

instrument chapter of the user's

guide to learn how to regenerate

catalyst).

Cause: Not enough catalysts in the

jar or reuse of disposable catalyst.

Action:

• See the Operating the instrument

section in the user's guide.

• Use multiple sachets or increase

the quality assurance (QA) level to

5, which allows more time for the

catalyst to react.

A weak or old catalyst takes

longer to react.

Loading...

Loading...