Chapter 7 Maintenance & service

38

Osmo1™ Single-Sample Micro-Osmometer Service Guide

Figure 50: Access the solenoid assembly inside Osmo1

2. Insert a disposable chamber cleaner into the sample

probe opening until you feel a positive stop.

3. Unscrew the two solenoid retainer bracket screws

and gently remove the bracket.

4. Being careful not to lose any small parts, grasp the

enclosed solenoid plunger assembly, lift it up, and

then withdraw it from the body cylinder

(stepFigure 51).

NOTE: Leave the body cylinder in place inside the

instrument.

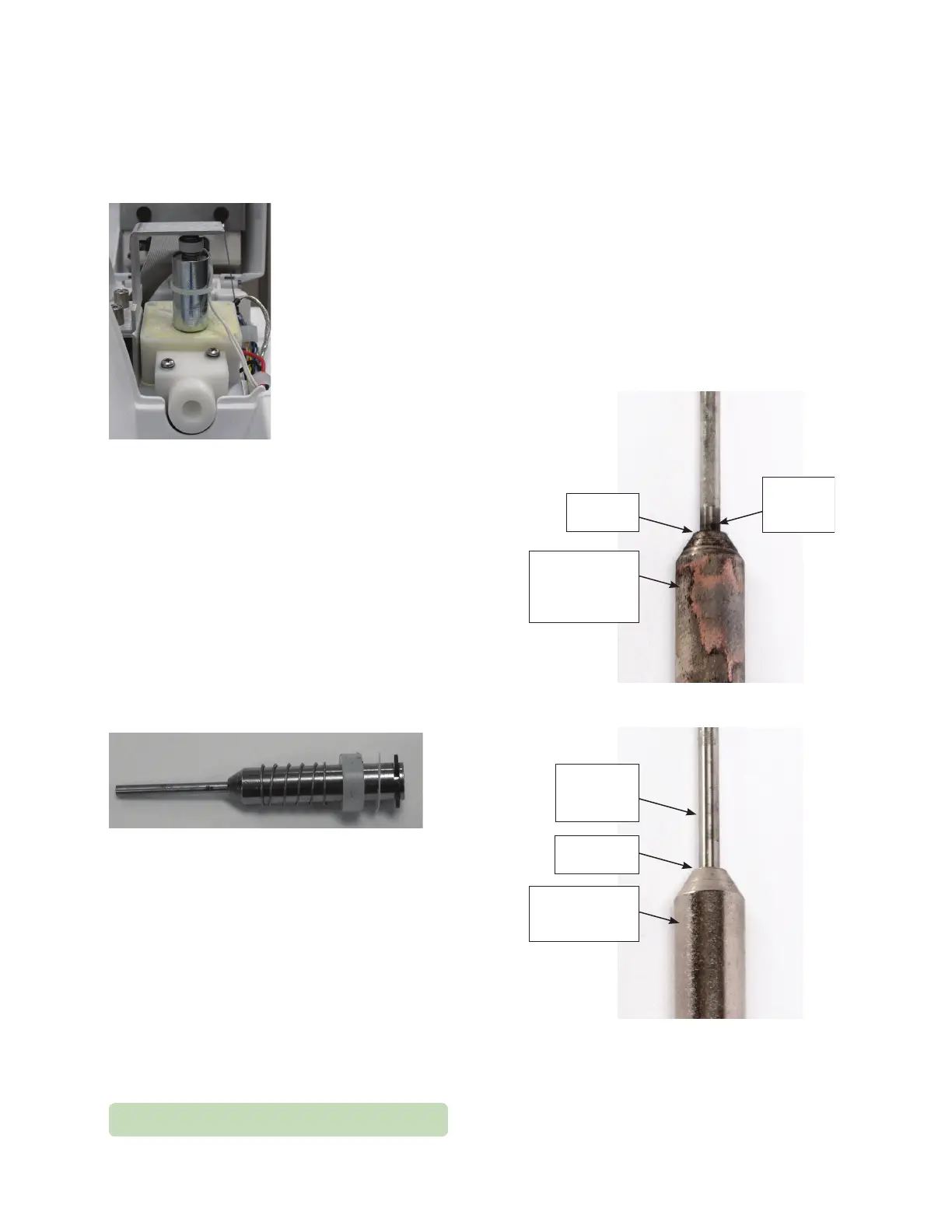

Figure 51: Solenoid plunger assembly

5. Dampen the wooden end of a cotton-tipped

applicator with a 70% isopropanol solution; then

insert it down through the solenoid body into the

smaller diameter plunger hole until it reaches the

chamber cleaner you inserted in step2.

Move the applicator in and out to scrub the sides of

the hole.

6. Clean the smaller diameter plunger of the solenoid

assembly with a 70% isopropanol solution on a soft

cloth.

Do not use any abrasive for this cleaning procedure.

7. Inspect the solenoid plunger for excessive wear and

deposits.

• If the plunger shows signs of fouling (Figure 52),

clean it with a lint-free cloth dampened with

isopropyl alcohol or a cleaning solution for protein

removal. (Thermo Scientific Orion Cleaning

Solution, part number 900021 is recommended.)

• If the plunger does not show signs of wear

(Figure 53), continue to step8.

Black

deposits

on shaft

Filings

present

Plating is

uneven, with a

dull, hammered

appearance

Figure 52: Solenoid plunger with visible signs of wear

No black

deposits

on shaft

No filings

present

Plating is

even, bright,

and shiny

Figure 53: Solenoid plunger with no signs of wear

Loading...

Loading...