EN

1205. 6755517_02

22

15.

The following tables highlight principle char-

acteristics for hydraulic circuit components,

whilst the graph on the following page

shows relative static pressures.

15.1. MINIMUM/MAXIMUM CONTENT OF

SYSTEM WATER

The minimum water content of system recommended

for units without hydronic kit is calculated using follow-

ing formula:

x 4

PFN: Nominal cooling capacity

That resulting minimum water content necessary for

correct function of system.

The adjacent table indicates maximum water capac-

ity in litres of hydraulic plant, compatible with expan-

WITH STORAGE TANK OR PUMP ONLY. The values

shown in the table refer to three maximum and

minimum water temperatures. If the effective water

-

tional conditions, another dimensioned expansion

vessel must be installed, using thenormal criteria,

with reference to the additional volume of water.

In the following tables it is possible to work out the

maximum values of the system also for glycoled

water functioning.

value by the corrective coefficient.

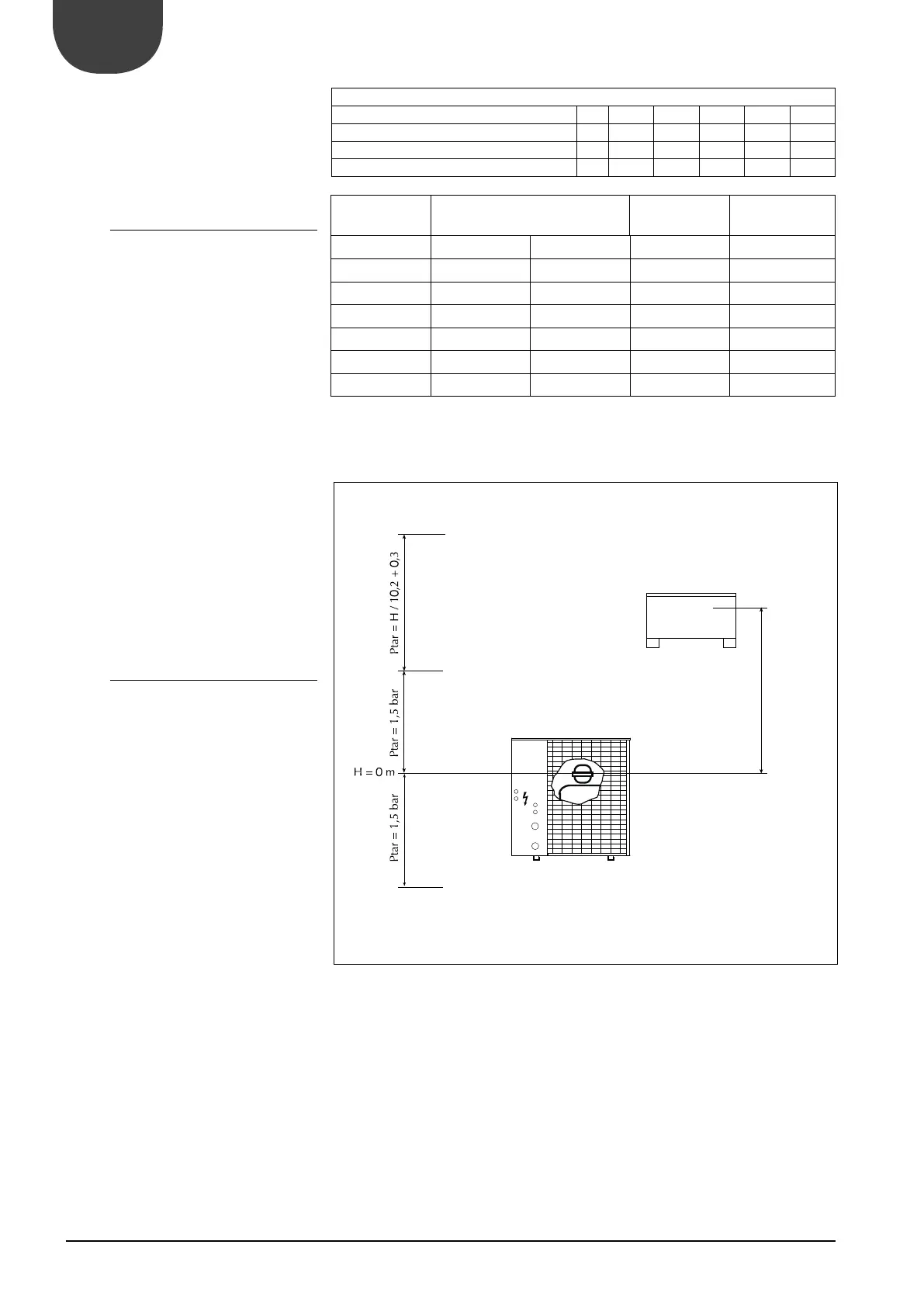

15.2. EXPANSION VESSEL CALIBRATION

Standard pre-load pressure value of expansion

vessel when empty is 1.5 bar, maximum value is

6 bar.

Calibration of the vessel must be regulated using the

by using the following formula:

calibration value of the vessel will be 2.3 bar.

If calibration value obtained from formula is less than

standard.

Hydraulic height

30 25 20 15

Calibration of expansion vessel bar 3.2 2.8 2.3 1.8 1.5

Water content reference values l

257 303 348 394 419

Water content reference values l

116 136 157 177 189

max. min.

10% 40 -2 0,507

10% 60 -2 0,686

20% 40 -6 0,434

20% 60 -6 0,604

35% 40 -6 0,393

35% 60 -6 0,555

Recommended operational conditions:

KEY

Check that highest installa-

tion is not higher than 55

metres.

-

lation can withstand global

pressure in that position.

Loading...

Loading...