30 Single-wheel power hoe 2100

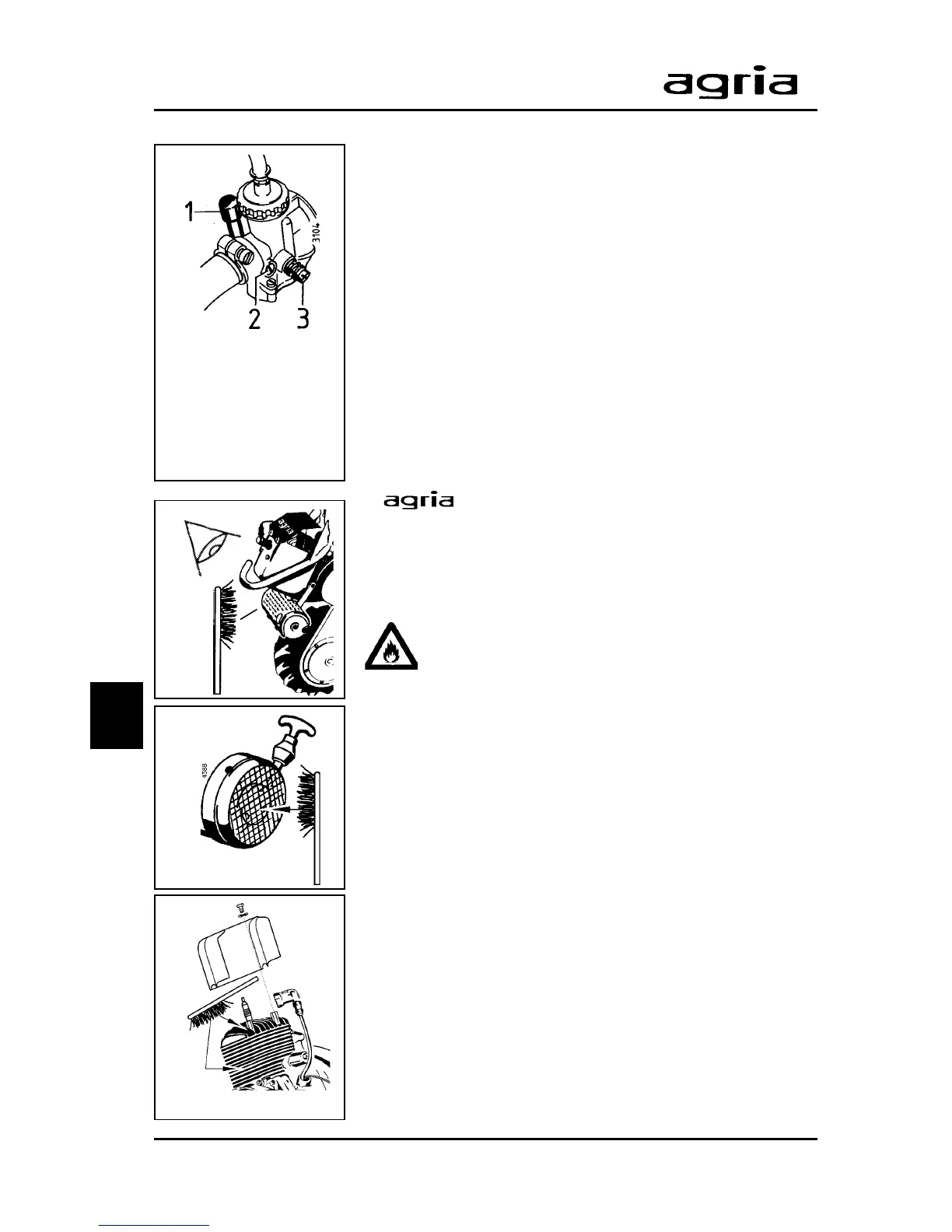

Carburetor Settings

Changes in fuel, temperature, height or strain can re-

quire slight re-adjustments of carburetor settings. Only

let engine run with air filter and air filter pot mounted.

Idling Speed

Always ensure that idling engine speed is adjusted cor-

rectly. At low speeds, the engine is supposed to run

smoothly, with speed control lever at stop in idling speed.

For basic tuning, adjust the slide valve adjusting screw

(3) on the slide carburetor. For this purpose, set the throt-

tle control cable free of play by turning the adjusting

screw on carburetor.

For fine tuning, adjust the air control screw (2). Adjust

only while the engine is still warm from operation (also

refer to “Specifications”).

-

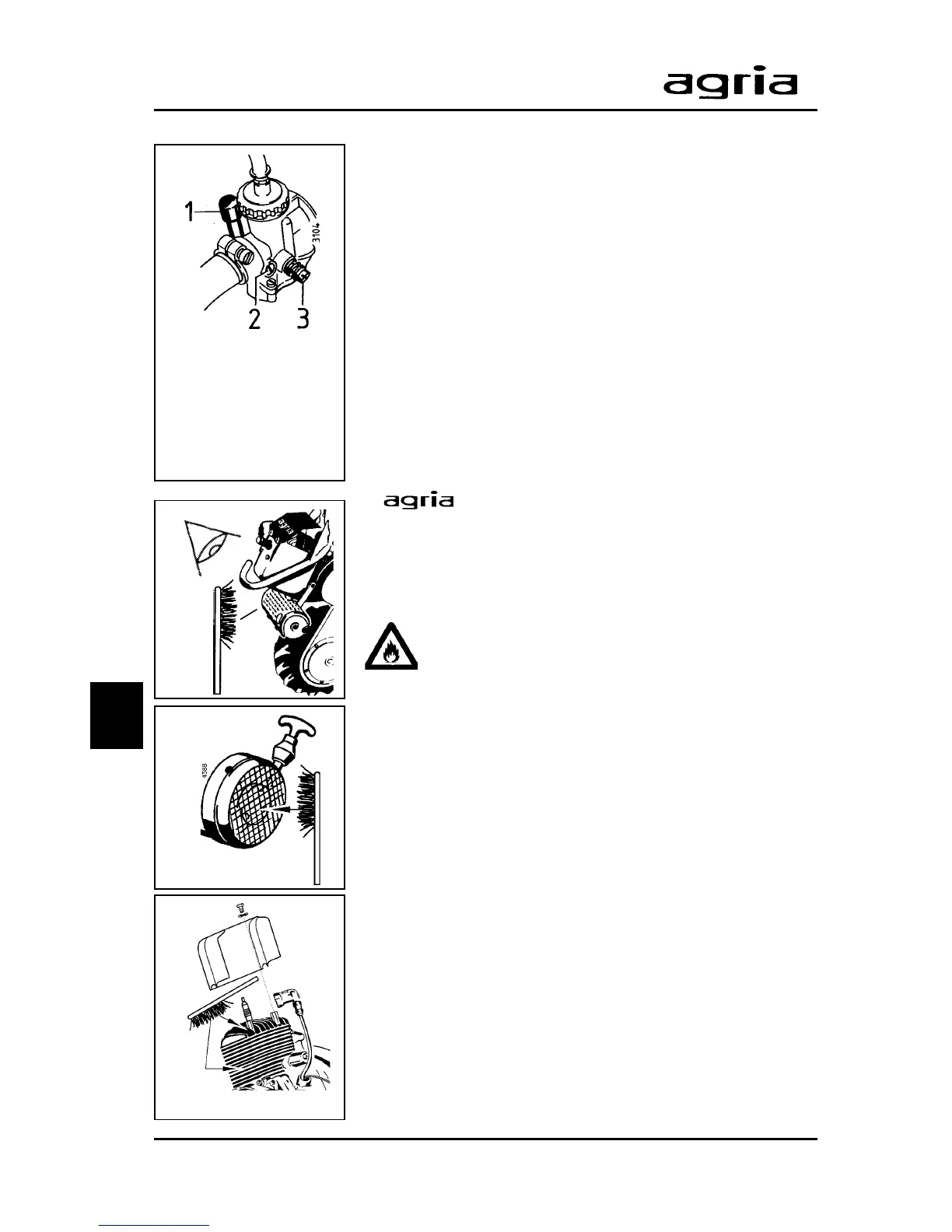

Service

Exhaust

Constantly check exhaust system (A/12) for plant

trash and clean, if necessary. Otherwise

danger of fire!

Check before each operation.

Check exhaust after every 200 operating hours for oil

carbon and, if necessary, clean or burn out.

Cleaning the Cooling-Air Screen

After long operation, dirt can clogg the cooling system.

To avoid overheating and damage to the engine, regu-

larly clean cooling-air screen (B/31). Check each time

before you take up operation!

Air-Cooling System

Clean internal cooling fins and surfaces at least eve-

ry 100 operating hours (earlier in very dusty condi-

tions).

5

5. Maintenance

1 Carburetor –

tickler

2 Air control

screw

3 Slide valve

adjusting screw

100 h

A

A

Loading...

Loading...