Appendix F. Calibration

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

Appendix F. Calibration

F.1 General

Calibration should be carried out to restore the accuracy of the device

NOTICE

Calibration must be performed only by fully qualified personnel.

– Calibration is performed using the reference signal source connected to the contacts

of the device. During the calibration the ratio between the input signal and the device

reference voltage is calculated.

– The calculated calibration coefficients are stored to non-volatile memory of the

device and used as a base for all calculations.

– Each analog input has its own calibration coefficients for each sensor type.

– If for some reasons the calculated coefficient exceedes the limits, error cause will be

displayed.

F.2 Analog input

Calibration for input signal 4-20 mA, 0-10 V, 0-4000 ohm

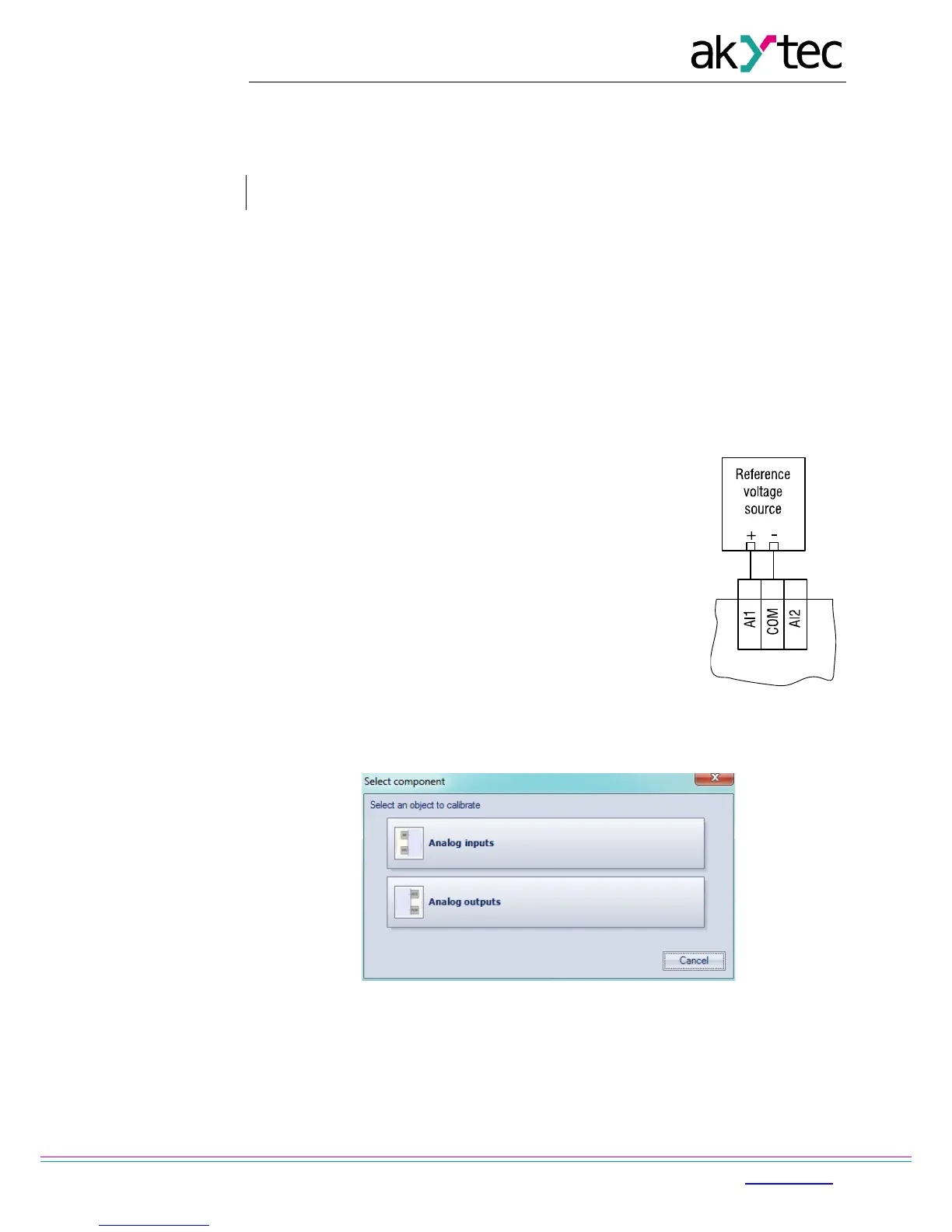

1. Connect the reference voltage source of accuracy class at

least 0.05 to the input AI1 (Fig. F.1).

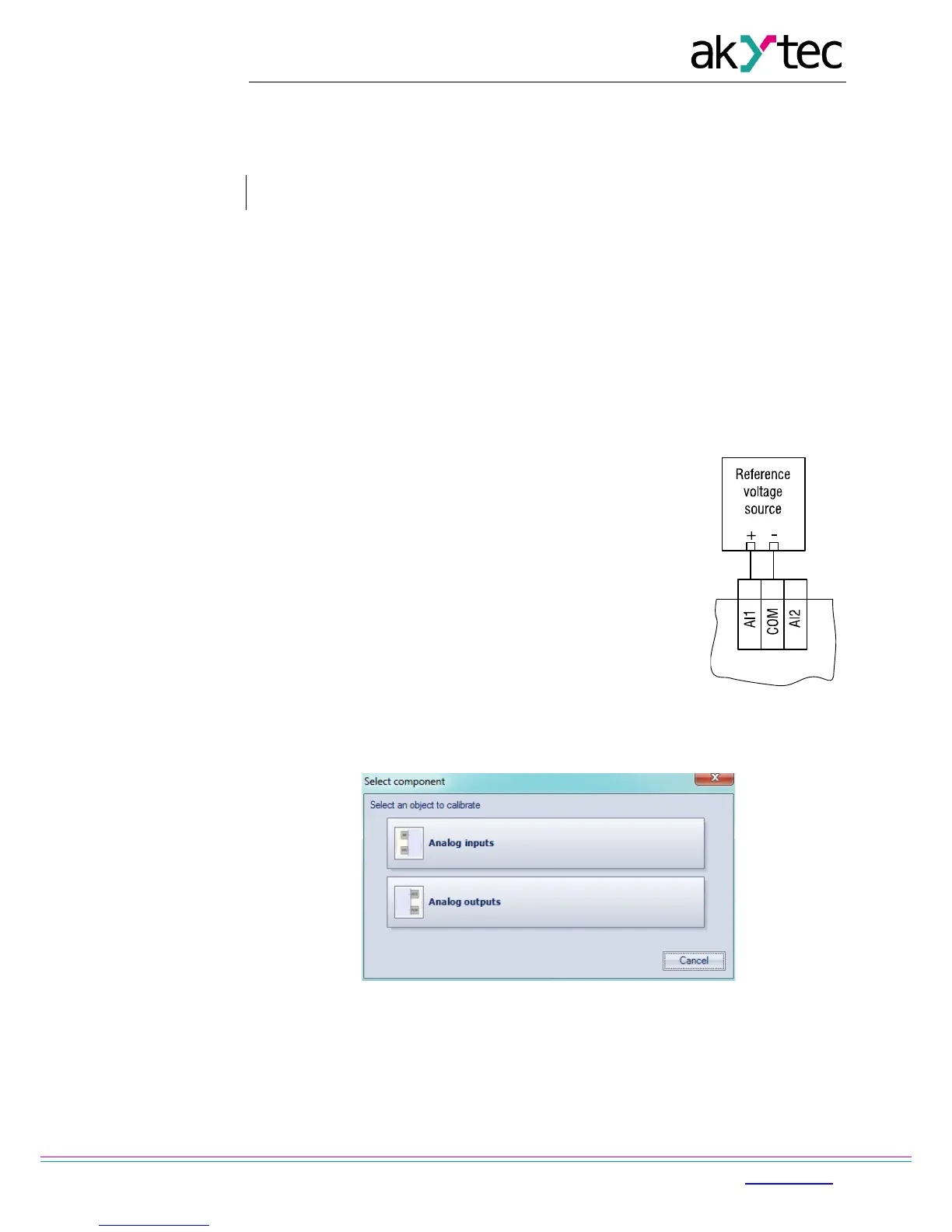

2. Start ALP software, select menu item Device>Calibration, in

the opened dialogue box select ‘Analog inputs’ (Fig. F.2)

3. Select the input signal.

4. Set the three curve points for calibration, the filter time

constant and select the channel (Fig. F.3). Increasing the filter

time constant increases the time of calibration but provides a

more precise calibration coefficients. Each channel is

calibrated individually. If ‘All channels’ is selected, all four

channels will be calibrated, so it is necessary to select the

appropriate curve points for all channels at once.

5. Click 'Next' to continue and follow the instructions.

Fig. F.1

Fig. F.2

Loading...

Loading...