Design a sequential function chart

18 Rockwell Automation Publication 1756-PM006I-EN-P - February 2018

The first step in the development of an SFC is to separate the configuration and

regulation of devices from the commands to those devices. Logix 5000 controllers

let you divide your project into one continuous task and multiple periodic tasks

and event tasks.

1. Organize your project.

These functions Go into this type of task

• Configure and regulate devices

Periodic task

Command a device to a specific state

• Sequence the execution of your process

SFC in the continuous task

2. For those functions that go in a periodic task, group the functions according

to similar update rates. Create a periodic task for each update rate.

For example, 2-state devices may require faster updates than PID loops. Use

separate periodic tasks for each.

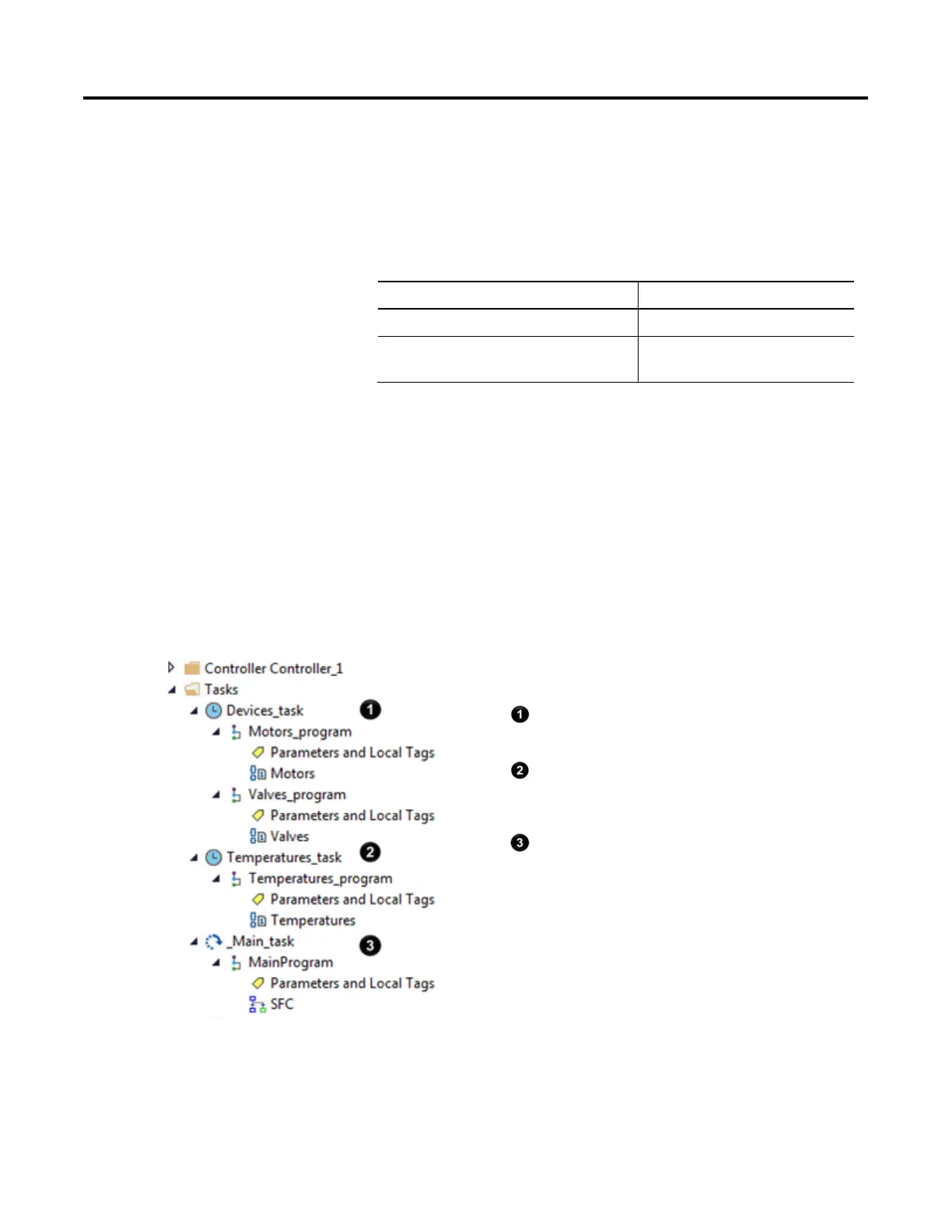

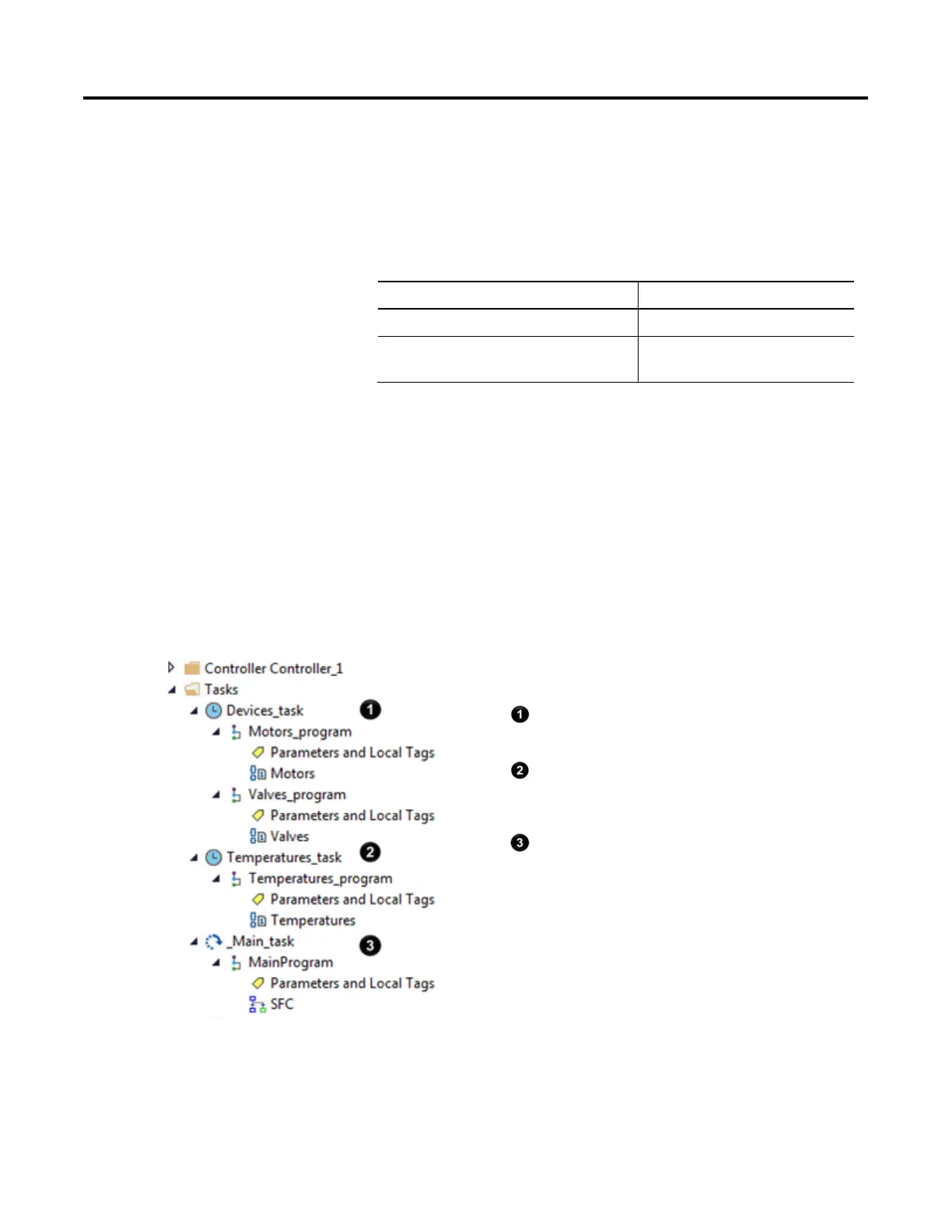

In this example, a project uses two periodic tasks to regulate motors, valves,

and temperature loops. An SFC controls the process.

Example

Define the Tasks:

This task (periodic) uses Function Block diagrams to turn on or off motors

and open or close valves. The SFC in MainTask commands the state for

each device. The Function Block diagrams set and maintain that state.

This task (periodic) uses Function Block diagrams to configure and

regulate temperature loops. The SFC in MainTask commands the

temperatures. The Function Block diagrams set and maintain those

temperatures.

This task (continuous) executes the sequential function chart (SFC). The

SFC commands the specific state or temperature for each device or

temperature loop.

Loading...

Loading...