Installation and Start-Up | 3-43

4. Disconnect the Vent tubing from the analyzer and plug it with a cap

fitting.

Open the Metering Valve and the Sample Flow Pressure Regulator

(regulator closest to the Sample Shut-Off Ball Valve on the Sample

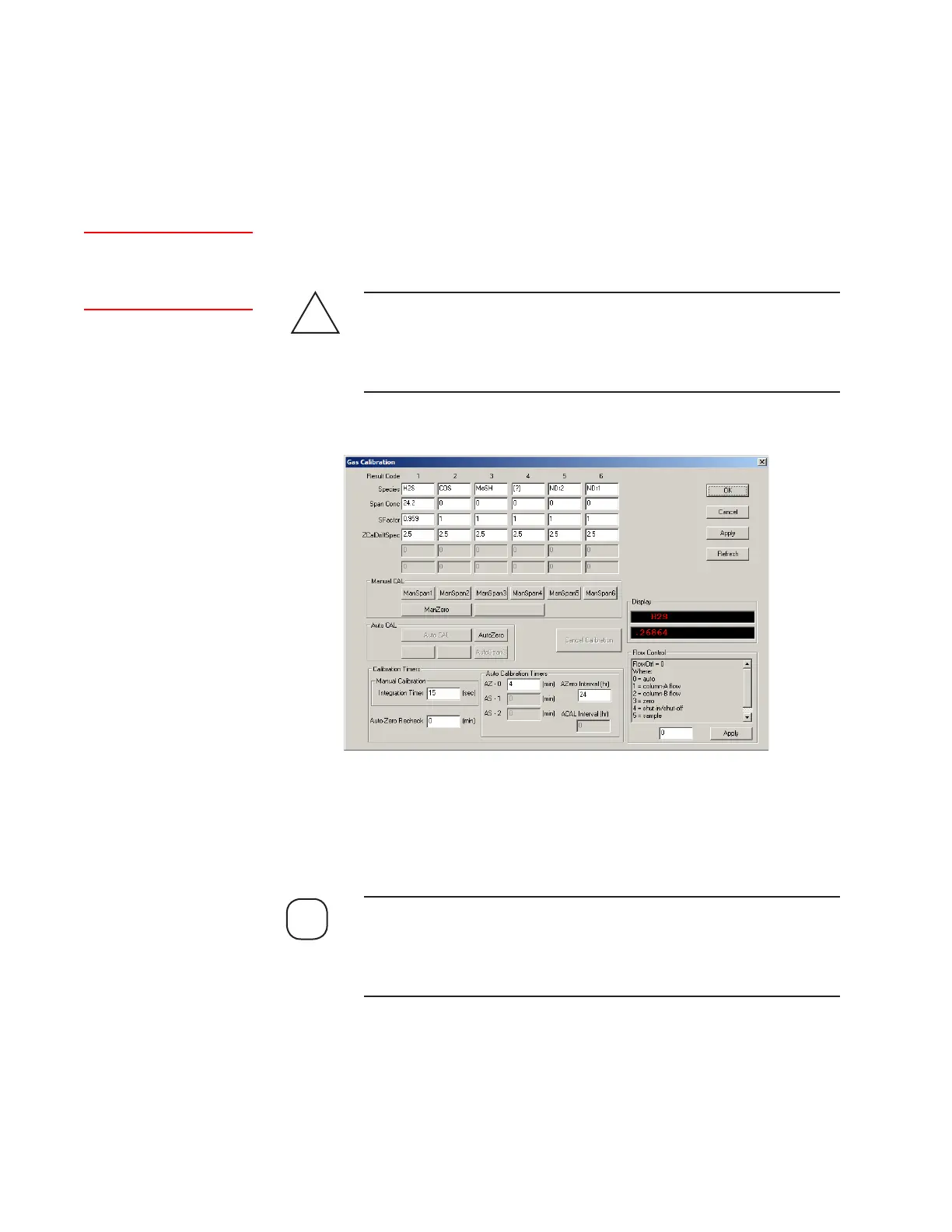

Inlet line).

5. Using the Configurator Software, change the Flow Control to ‘2’

(zero). Click OK then Apply. Do not save the changes to EEPROM.

If the optional pressure transducer is installed do not set the pres-

sure higher than its upper pressure rating. Refer to Final “As-Built”

drawings in the analyzer Documentation Package for details about the

pressure transducer rating.

!

CAUTION

Setup (tab)

Gas Calibration<<Flow

Control>>

6. Use the Zero/Aspirator Pressure Regulator to pressurize the sample

system to 70 KPA (10 PSI) higher than the recommended sample

pressure.

The Sample Pressure Gauge and the Zero Gas Pressure Gauge must

be set at the same pressure to avoid one leaking into the other. Adjust

the Zero Gas Pressure Regulator until these pressure readings are the

same.

NOTE

Figure 3-21.

Gas Calibration dialog

box (Model 932S).

Loading...

Loading...