76 ARR1575

3 3

22

1

1

555094

2.8. How to transport the Machine

• The machine can move on its own between working sites.

When moving on the working site, observe the safety

measures applicable to the working site.

When driving for long distances, 1-hour cooling breaks

after 3 hours of driving should be taken. Failing that, you

are exposed to the risk of damage to the machine for

which the manufacturer is not responsible.

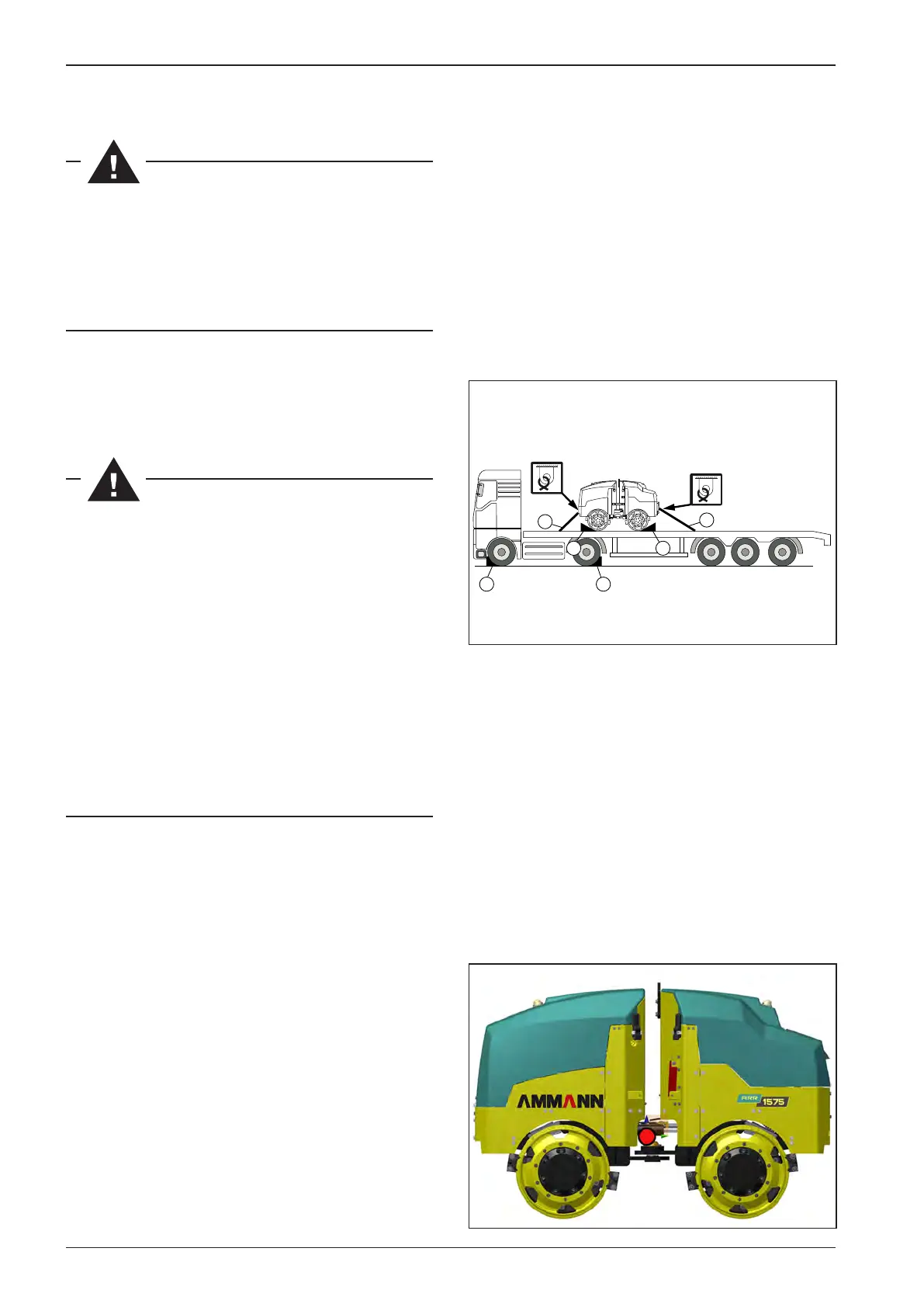

• When on the road, the machine should be transported on

avehicle.

When transporting the machine on a vehicle, observe

the regulations in force in the given territory.

Make sure the transport carrier is braked and mechani-

cally secured against undesired motion with scotch

blocks (3) when loading or unloading.

When moving onto the transport carrier you must switch

ON the function of Drum Slip Limitation. At the same

time we recommend to put rubber bands or wooden

planks, etc. underneath the drum.

The machine on the vehicle must be properly tied and

mechanically secured against longitudinal and lateral

displacement as well as against tipping (1). The drums

must be secured using scotch blocks (2).The maximum

force permitted for tying the machine to a transport ve-

hicle is 2.5 t.

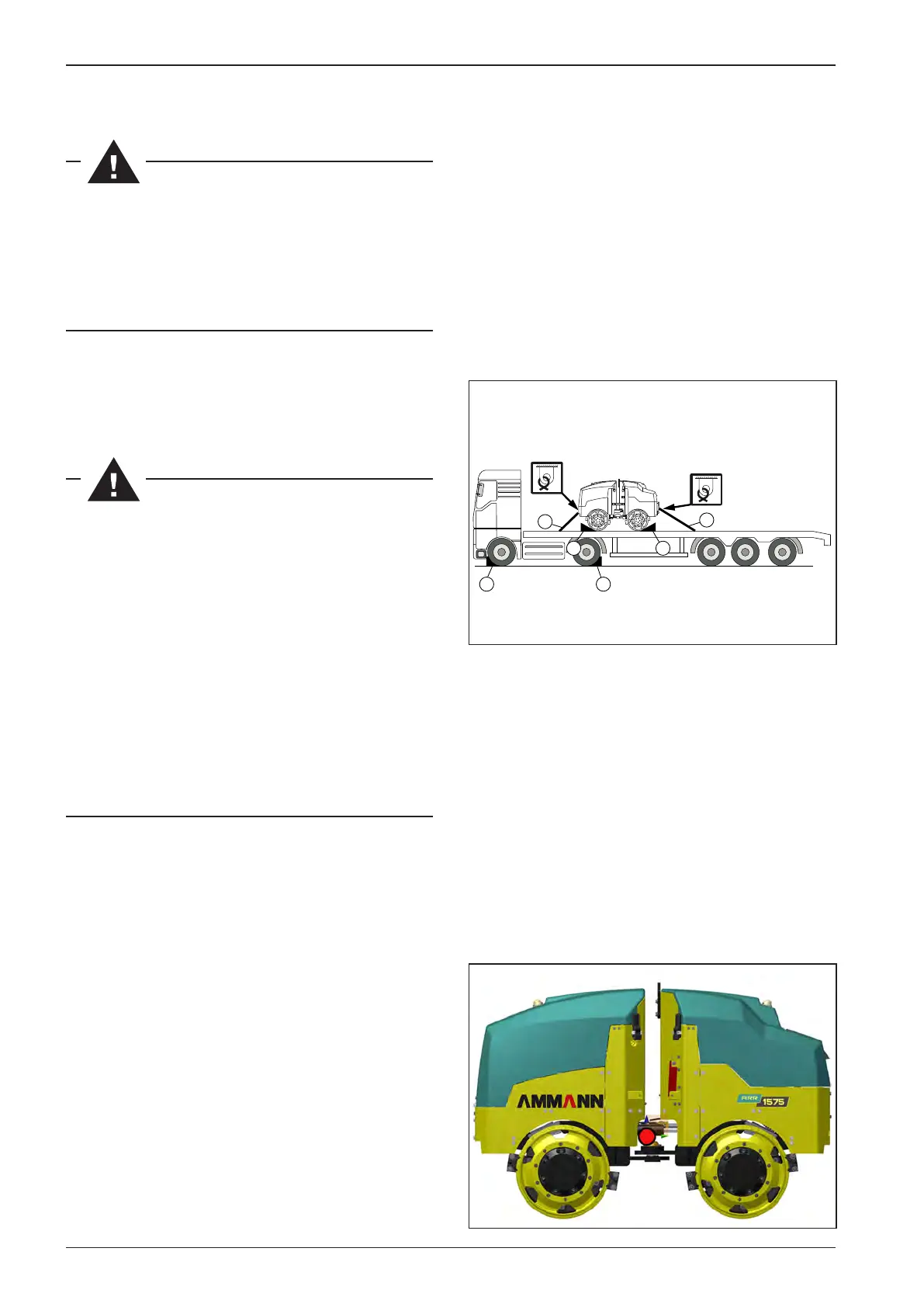

Center of gravity

The center of gravity relevant to transport is located 460 mm

from the oor and approx. in the center of the machine, de-

pending on the ll level of the diesel or water tanks.

Loading...

Loading...