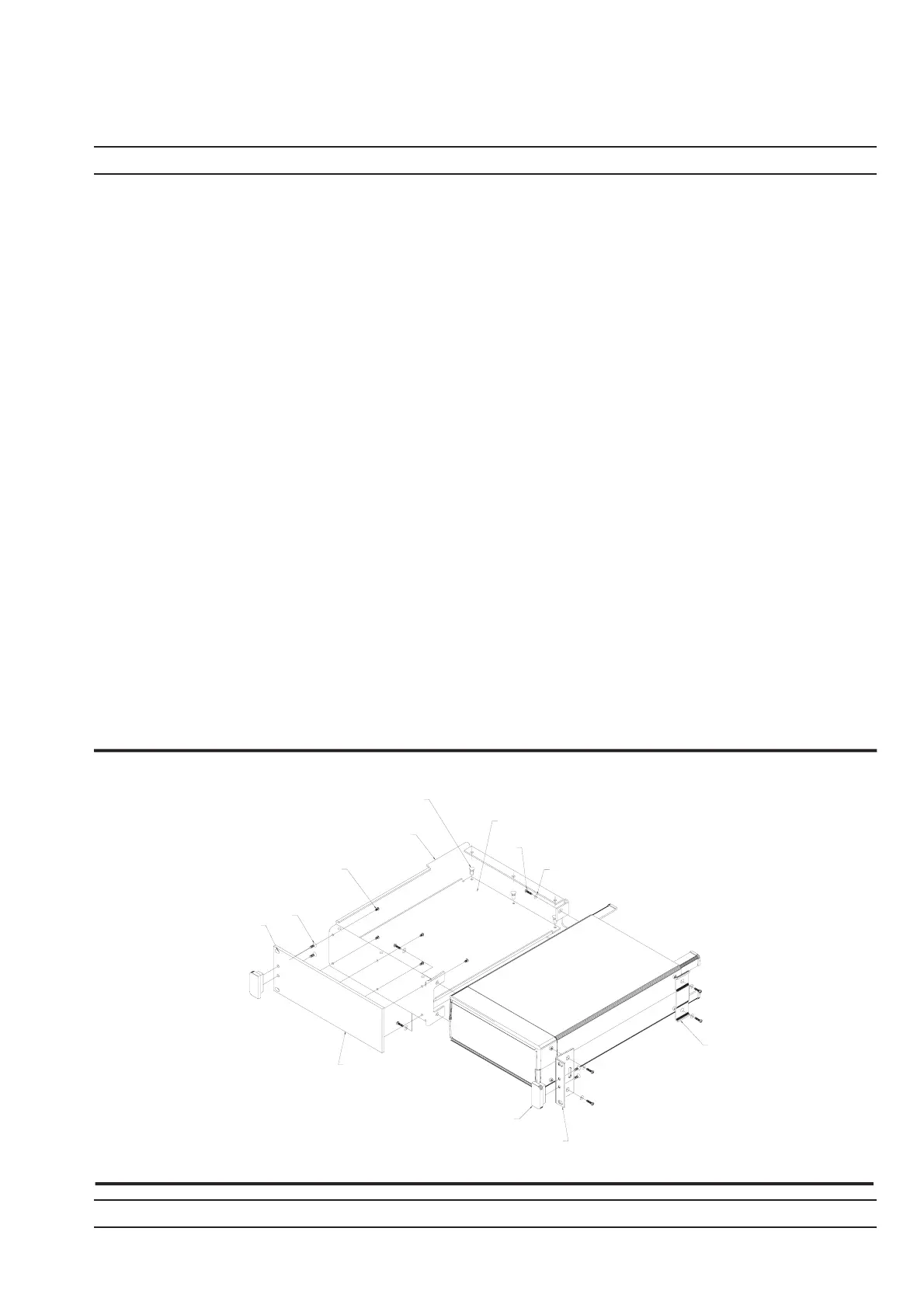

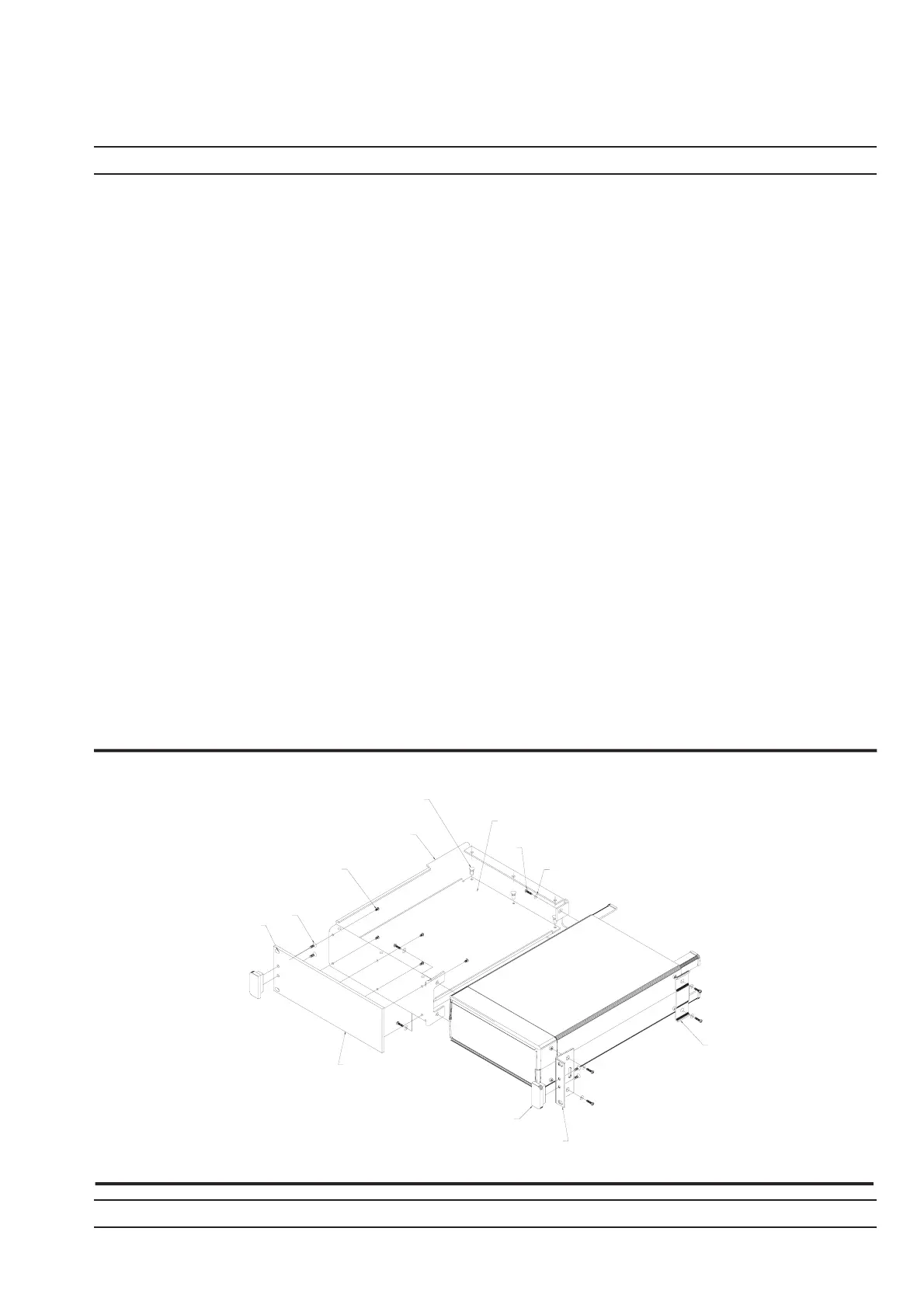

3. Lay the large support bracket D41473 next to the Power Meter as per the as-

sembly drawing. Note if the PM needs to be mounted on the left hand side of

the rack, simply lay the bracket on the PM,s right side. i.e. a mirror image of

the assembly drawing.

4. Locate the support bracket on the four PM case pillars. Secure with 4 screws

905-68 and 4 washers 900-345. (See max. torque settings page 2-4).

5. Locate the front rack mounting bracket C37276 at the front of the PM on the

other side to the large support bracket with two screws 905-68 and two

washers 900345. (See max. torque settings page 2-4).

6. Locate the rear bracket C41449 at the back of the PM on the other side to the

large support bracket with two screws 905-68 and two washers 900-345. See

maximum torque settings above. Locate the rear bracket C41449 at the back

of the PM on the other side to the large support bracket with two screws

905-68 and two washers 900-345. (See max. torque settings page 2-4).

7. Fit the front plate 49362 with 6 screws 905-72. (See max. torque settings

page 2-4).

8. Position the base panel 49361 as shown in the drawing, and secure with 6

snap rivets 788-575.

9. Fit the four speed nut 790-319 to the rack in the correct place to allow mount-

ing of the PM in the rack.

10. Slide the PM into the rack and secure with 4 decorative screws 900-821.

ML2400A OM 2-5

INSTALLATION RACK MOUNTING

49362

FRONT PLATE

900-795

X4

905-72

X6

SCREW

041473

SUPPORT

BRACKET

49361

BASE PANEL

788-575

X6

SNAP RIVET

PRESS DOWN CENTER

PIN USING A FLAT EDGE

905-68

X8

900-345

X8

C41449

RACKMOUNT

BRACKET

REAR SUPPORT

C37276

RACKMOUNT

SIDE BRACKET

783-1055

HANDLE

X2

NOTE:

FIT COMPLETED

ASSEMBLY TO RACK USING

DECORATIVE SCREW 900-821

X4 AND SPEED NUT 790-319

X4 IN 4 CORNER

POSITIONS AS SHOWN

Loading...

Loading...