7032 SOUTH 196th - KENT, WA 98032 - (253) 872-0141 / FAX (253) 872-8710

OPERATION / MAINTENANCE MANUAL

MODEL 50 VIBRATORY HAMMER WITH MODEL 260 POWER UNIT

I. GENERAL INFORMATION (Continued...)

I-3B. The Vibrator Gearbox

The vibrator gearbox contains two high amplitude eccentric weights cast in one piece with the gear.

The counterweight is filled, and therefore, enhanced with lead to increase eccentric moment. This

design is unique to the industry and was developed by the engineers of APE to solve a number of

problems associated with other types of vibrator machines. Both the eccentric and the drive gear

have been helically cut to provide high speed operation with reduced noise and wear. Vibration is

caused by the vertical movement created when the eccentrics are rotated. The eccentric and drive

gear are driven in line by one Volvo motor mounted on the outside face of the gearbox. The motor

is recessed for maximum protection. The eccentrics rotate on two shafts housed by four giant

spherical bearings. The gears and bearings receive lubrication as a result of the fluid splashing inside

the gearbox when the gears are rotated. The oil level is quickly determined by looking at the site

gauge. The Model 50 can be operated under water to a depth of 30 feet without modifications.

(Consult factory for depths below 30 feet.)

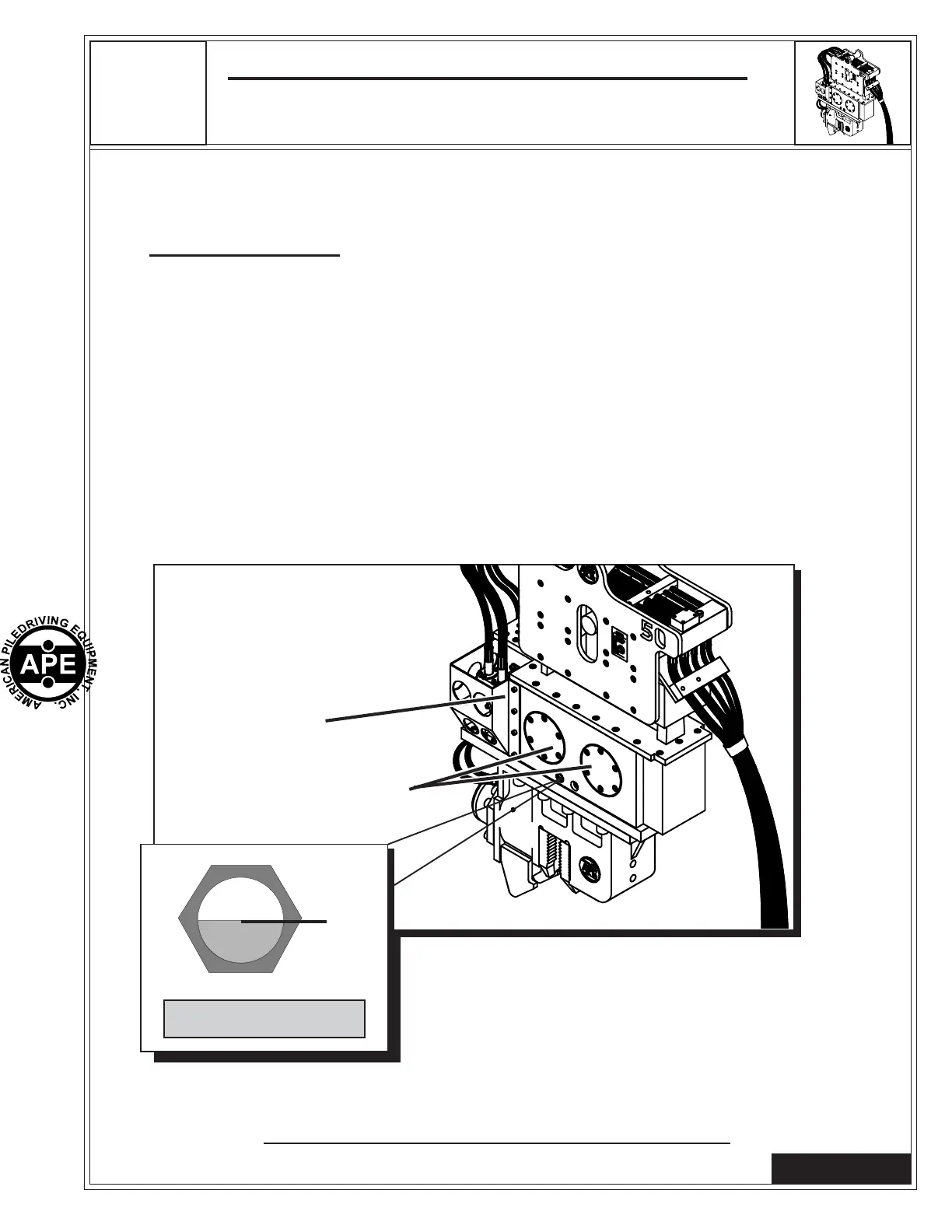

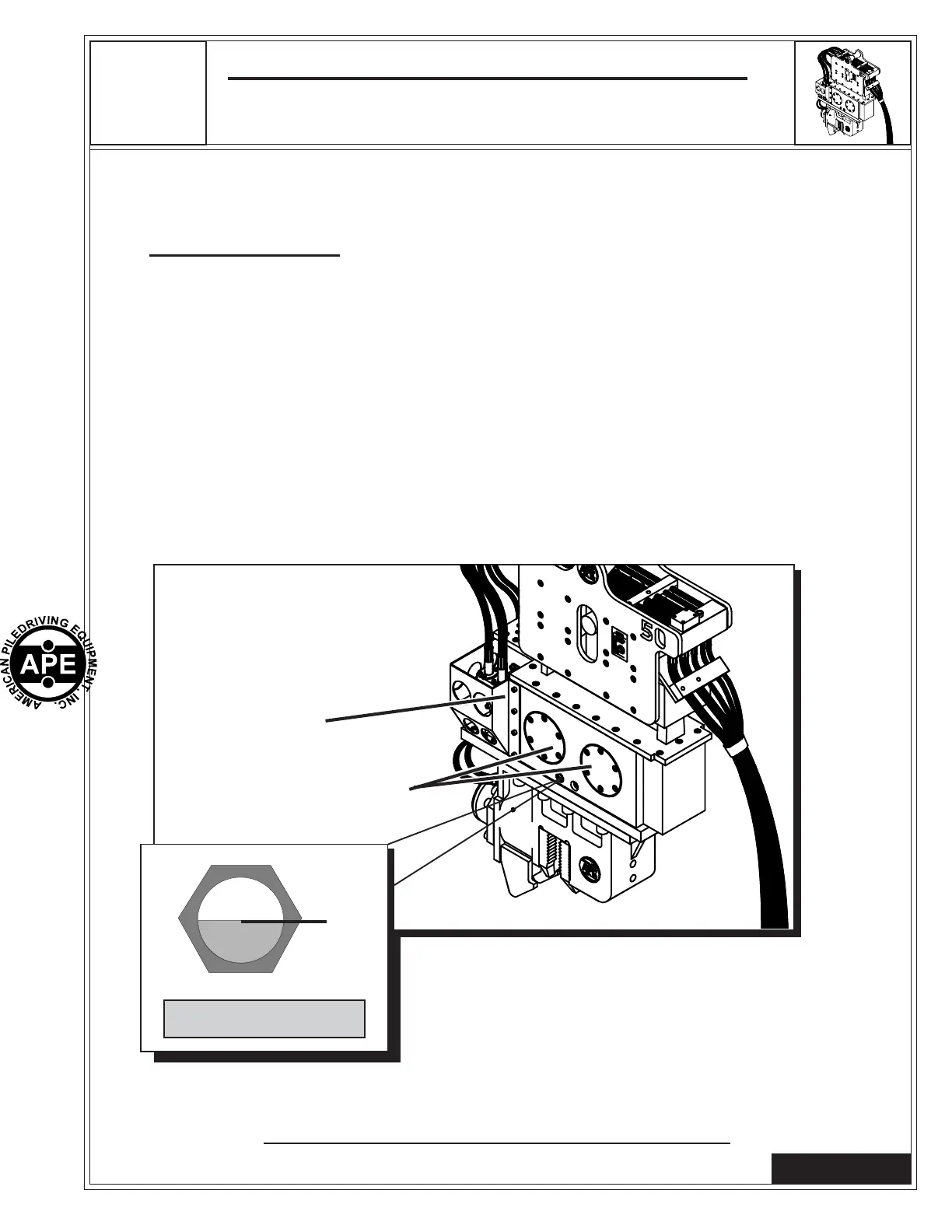

Figure 1-D. General Description of Vibrator Gearbox.

Page 1-5

Hydraulic Motor

(Volvo f12-110)

Eccentric Bearing Covers

Oil

Level

GLASS SIGHT GAUGE

CHANGE OIL ONCE PER WEEK

OR WHEN BLACK

(Applies to all Model 50 vibros regardless of

suppressor type)

Loading...

Loading...