27

SECTION 6

OIL, FILTER AND LUBRICATION INFORMATION

dislocating the bearing seals due to excessive grease pres-

sure.

Do not use high pressure or excessive amounts of grease.

Damage to the bearing seals could result.

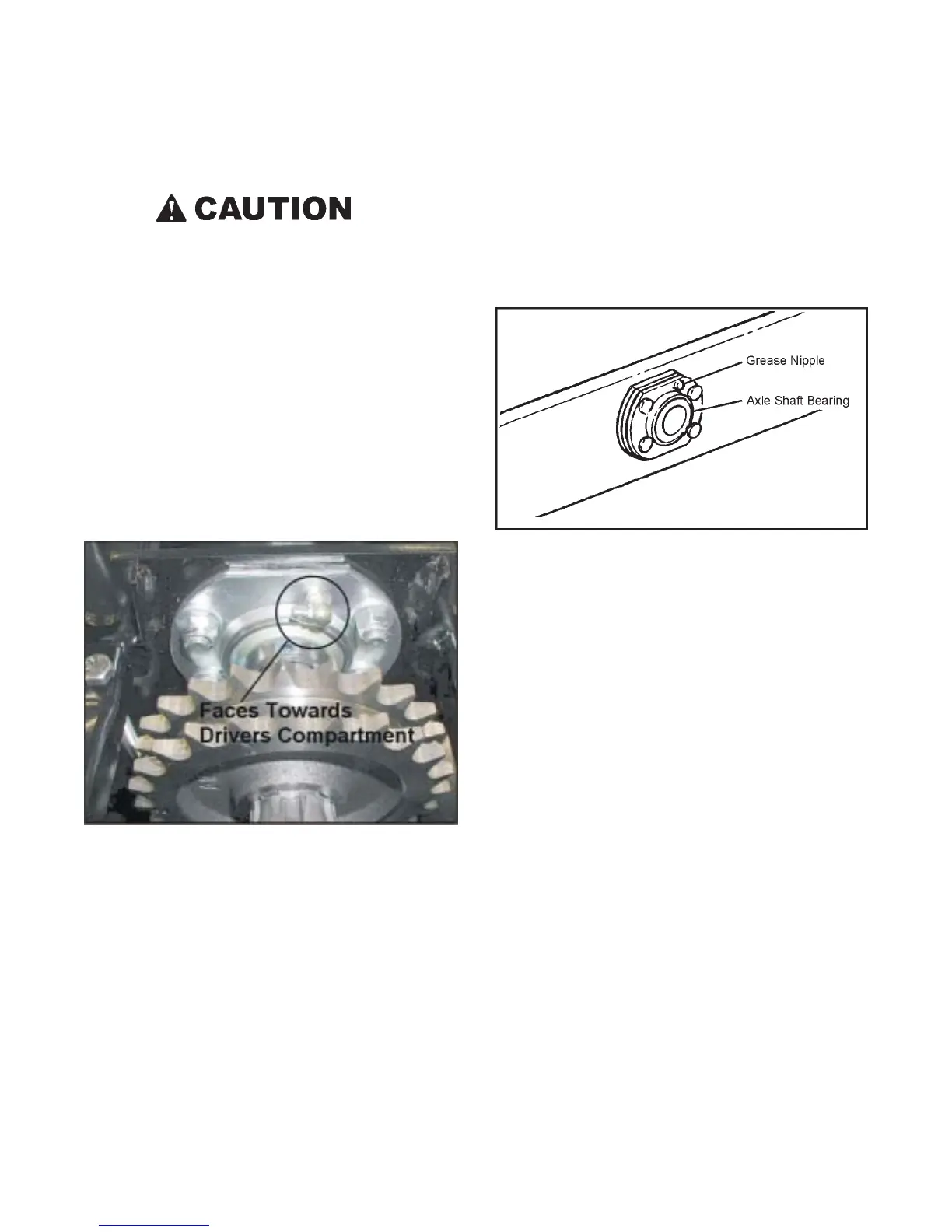

6.4.6 Idler Shaft Bearing Lubrication - All models except

FRONTIER and AVENGERS

The idler shaft bearing flanges are fitted with grease nipples

(Figure 6-11). The inner bearing flange utilizes a right angle

grease fitting to the top of the flange, which faces back to-

wards the driver's compartment. Easily accessible, this pro-

vides a convenient method of greasing the inner bearings. A

grease gun fitted with a flexible extension is required. These

bearings should be greased with a small amount of a lithium

based, NLGI #2 or 3 mineral oil based grease, (such as Shell

Alvania #3). Apply every 100 hours of operation or whenever

major maintenance is performed on the vehicle.

Figure 6-11. Idler shaft bearing grease nipples.

6.4.6 Idler Shaft Bearing Lubrication - FRONTIER and

AVENGER Models

Left and right hand side inner idler shaft bearings are fitted

with a right angled grease fitting. With the front floor pan

removed, the left side idler shaft grease fitting is accessible

at the bottom of the bearing flange. The right side idler shaft

grease fitting is located at the top of the flange. Both of these

can be accessed conveniently with a grease gun fitted with

a flexible extension head. Grease with a small amount of a

lithium based, NLGI #2 or 3 mineral oil based grease, (such

as Shell Alvania #3). Apply every 100 hours of operation or

whenever major maintenance is performed on the vehicle.

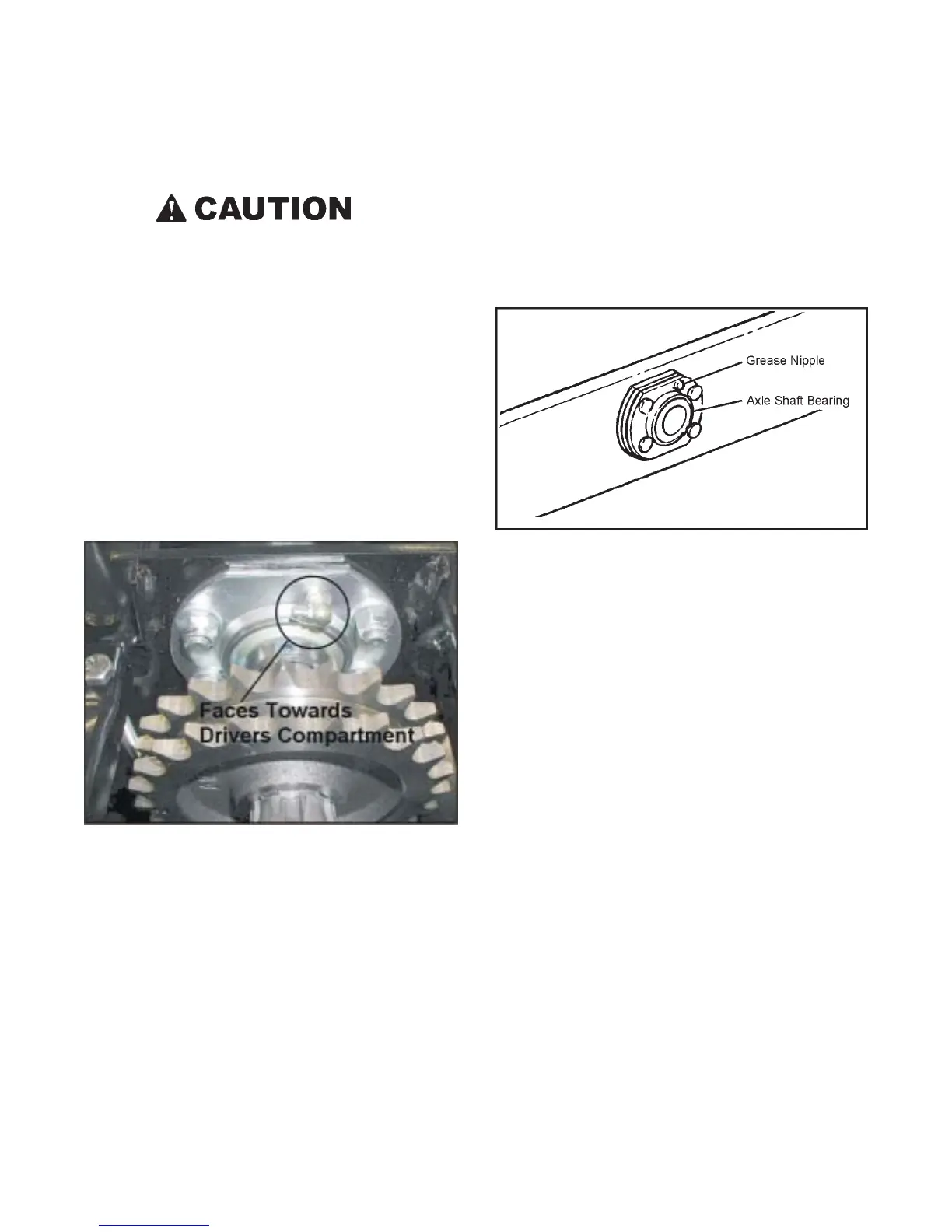

6.4.7 Inner Axle Bearing Lubrication

The inner axle flanges are equipped with a grease nipple.

( Figure 6-12) Lubricate the bearings with a small amount of a

lithium based, NLGI #2 or 3 mineral oil based grease, (such as

Shell Alvania #3). Apply every 100 hours or before the vehicle

is taken out of service for any extended period. Only a small

amount of grease is required.

Figure 6-12. Inner axle flange grease nipple.

Loading...

Loading...