28

Checking the Fluid Level

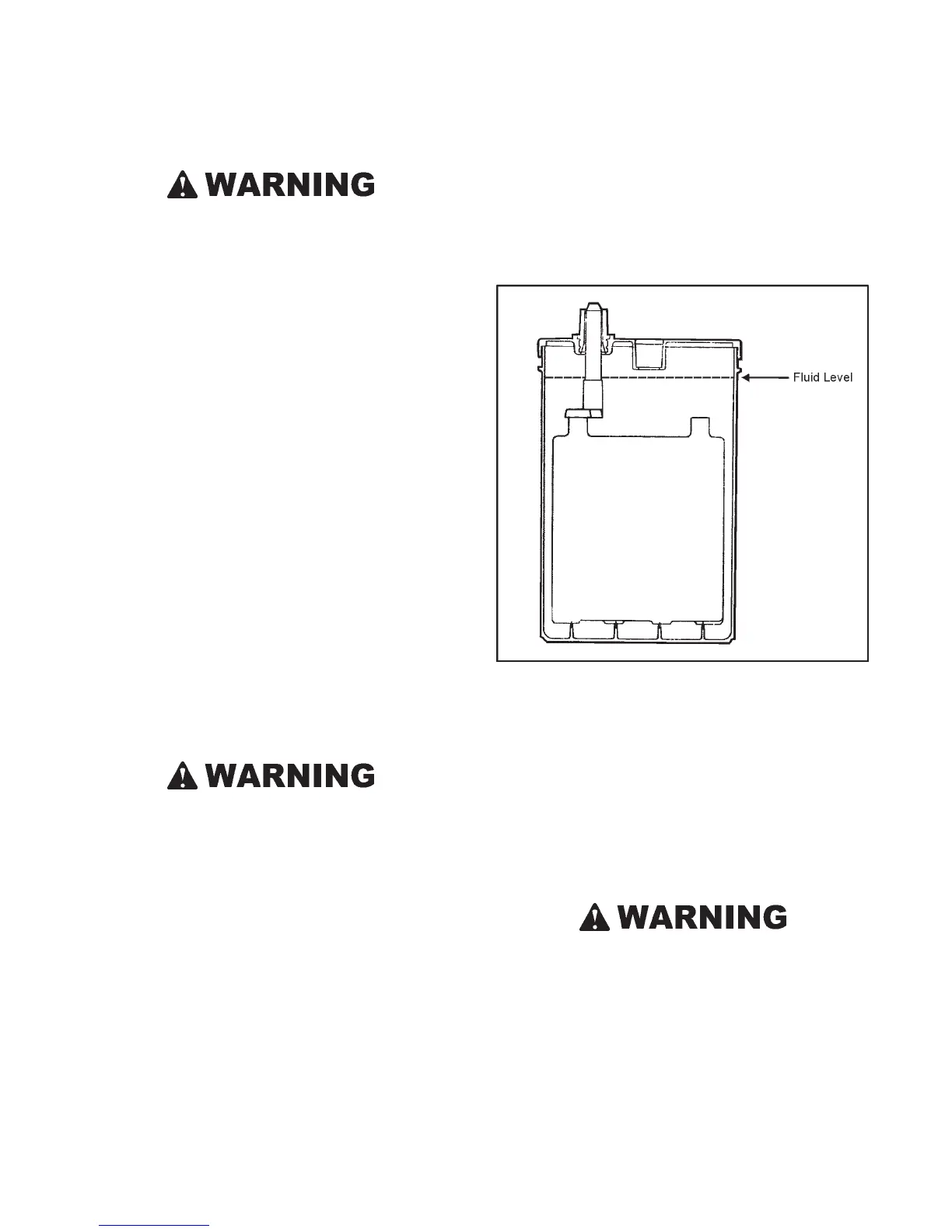

Check the fluid level every 50 hours of operation. Remove the

pod vents and make sure each cell is filled to the fluid level as

shown in Figure 7-1. If the fluid has dropped below the fill

well, add distilled water until the cell is filled to correct level.

DO NOT OVERFILL.

Figure 7-1. Battery fluid level

Charging the Battery

If the battery loses its electrical charge, remove the battery

from the ARGO and recharge it with a 12 volt battery charger

at the rate of 10-12 amps maximum. The battery should remain

on charge until the specific gravity reaches 1.265 on a hy-

drometer. Re-install the battery in the vehicle and try to start

the engine. If the battery fails to perform properly, have it

tested by a battery service dealer. Replace a defective battery

with ARGO Part No. 127-54/Exide Part No. 45-50.

Ventilate area when charging. Keep away from spark,

heat, cigarettes or open flame.

Cleaning the Battery Terminals and Cable Connections

Clean the battery terminals and cable connections every 100

hours. Remove the black NEGATIVE (-) cables first. Make

sure you reconnect the NEGATIVE (-) cables to the NEGA-

TIVE (-) post and the red POSITIVE (+) cables to the POSI-

TIVE (+) posts. Damage to the electrical system will occur if

the cables are reversed.

7.1 ELECTRICAL SYSTEM

Detailed information on standard workshop and safety

procedures and general installation practices is not

included here. ODG assumes no responsibility or li-

ability for PERSONAL INJURY or VEHICLE DAMAGE

which results from any procedure performed, includ-

ing those procedures outlined here. Before performing

any procedure, an individual must have determined to

his/her satisfaction that personal injury or vehicle dam-

age will not result from the procedure, working envi-

ronment or tools selected.

7.1.1 General

To prevent damage to the electrical system:

• Never weld on the vehicle without first disconnecting both

positive and negative battery cables. Make sure the part

you are welding is properly grounded.

• Connect battery booster cables properly, positive to posi-

tive and negative to negative. Connect negative cable

last, disconnect first. It is not a recommended practice to

boost your argo if the battery is dead. If possible, avoid the

use of booster cables from an external battery source.

Damage can occur to the engine ignition system.

• Connect switch terminals properly, especially the ground

wire.

7.1.2 Battery - ARGO Part No. 127-54

- Exide Part No. 45-50

Battery fluid contains sulphuric acid. If battery fluid

comes in contact with skin or eyes, flush thoroughly

with water. If swallowed, call physician or poison con-

trol centre immediately. KEEP AWAY FROM CHIL-

DREN. Serious personal injury can occur. Always wear

rubber gloves and safety glasses when servicing the

battery.

Batteries can explode and cause serious personal in-

jury if exposed to flame or sparks. Never smoke while

servicing the battery.

All C, R, B, N, S and A models are equipped with a 12 volt, wet

cell type battery. The battery is located in the engine com-

partment, on the right side in front of the driver’s position.

The battery on the AVENGER and FRONTIER models is lo-

cated beneath the drivers bench seat, along side the fuel tank,

to the right side of the driver.

SECTION 7

MAINTENANCE INFORMATION

Loading...

Loading...