51

SECTION 11

ACCESSORY INFORMATION

Centre the track pin so that it does not stick out on

either side of the track.

2. Apply a drop of blue 242 Loctite to the hole in the lock

bushing and the set screw. Install the set screw using a 1/

8" Allen wrench. TIGHTEN SECURELY. Set screw must

seat in ground recess of track pin.

3. Assemble two complete tracks:

6 wheel models - 29 segments each side

- 1 half segment

8 wheel models - 36 segments each side

- 1 half segment

IMPORTANT: The actual number of track segments

used will vary and will be determined when the tracks

are being installed. Wrap the track assembly around

the tires. Ensure they are snug to the front and rear

deflated tires. Then add or remove segments until there

is a gap of approximately 2" to 2-1/2" between the ad-

joining segments. These will have to be drawn together

using two C-clamp style vise grips to install the con-

necting pin.

Supertrack & Rubber track systems require the assem-

bly of 605-77 axle extensions and 126-08 extension

studs to each wheel hub before installation of the tracks.

Failure to install these components will cause severe

damage to the lower body.

Note: Axle extensions are recommended for use only

with Argo Super tracks and Rubber tracks and should

be removed for tire-only use.

11.3.2 Installing the Axle Extension (Supertrack & Rubber

Track)

4. Raise the vehicle off the ground and remove the wheels

using 3/4" socket.

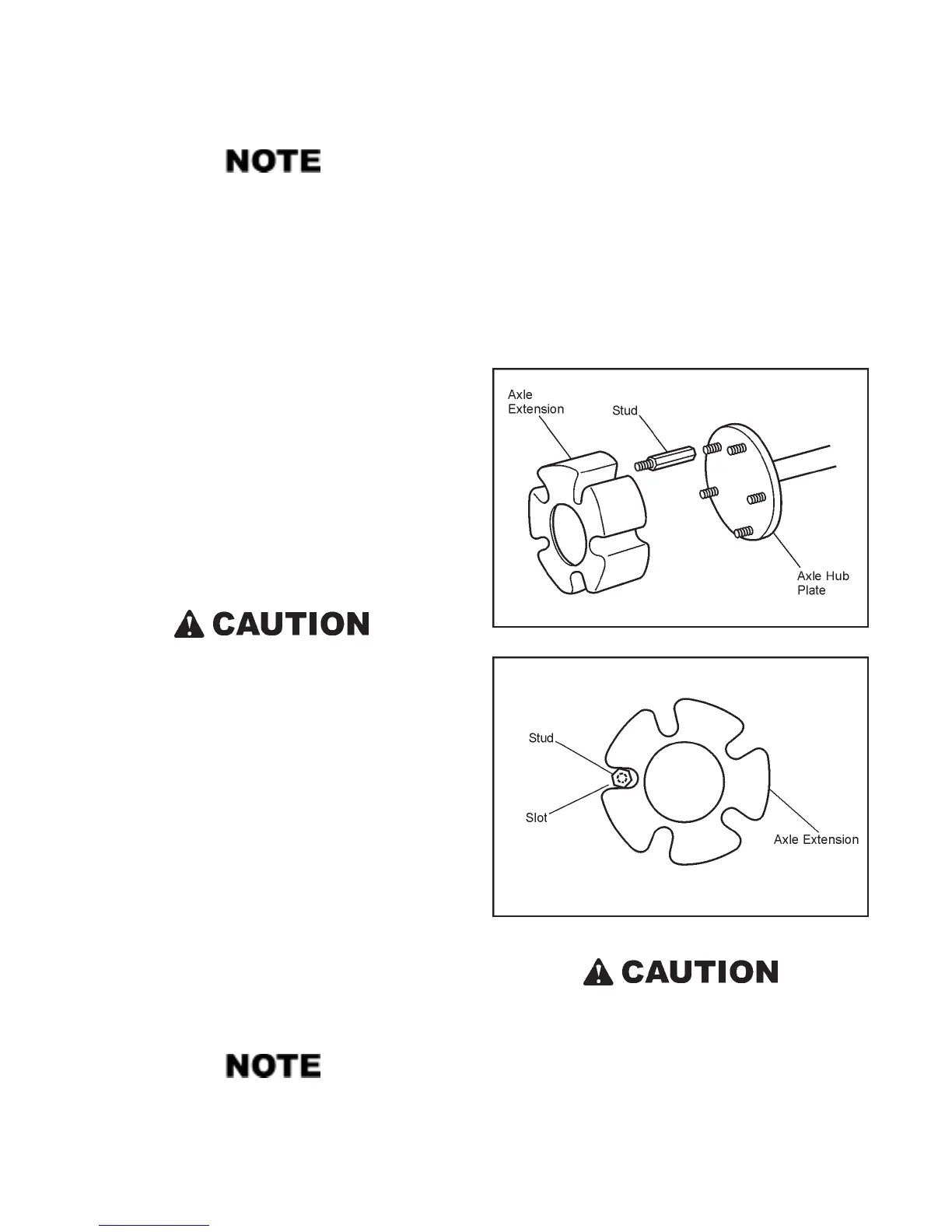

5. Install the extension studs on all of the vehicle wheel studs

and tighten securely with a 5/8" socket. See Fig. 11-3.

6. Place the axle extension collars onto the extension studs

and seat firmly against the axle hub plate. The small hole

must face away from the hub plate.

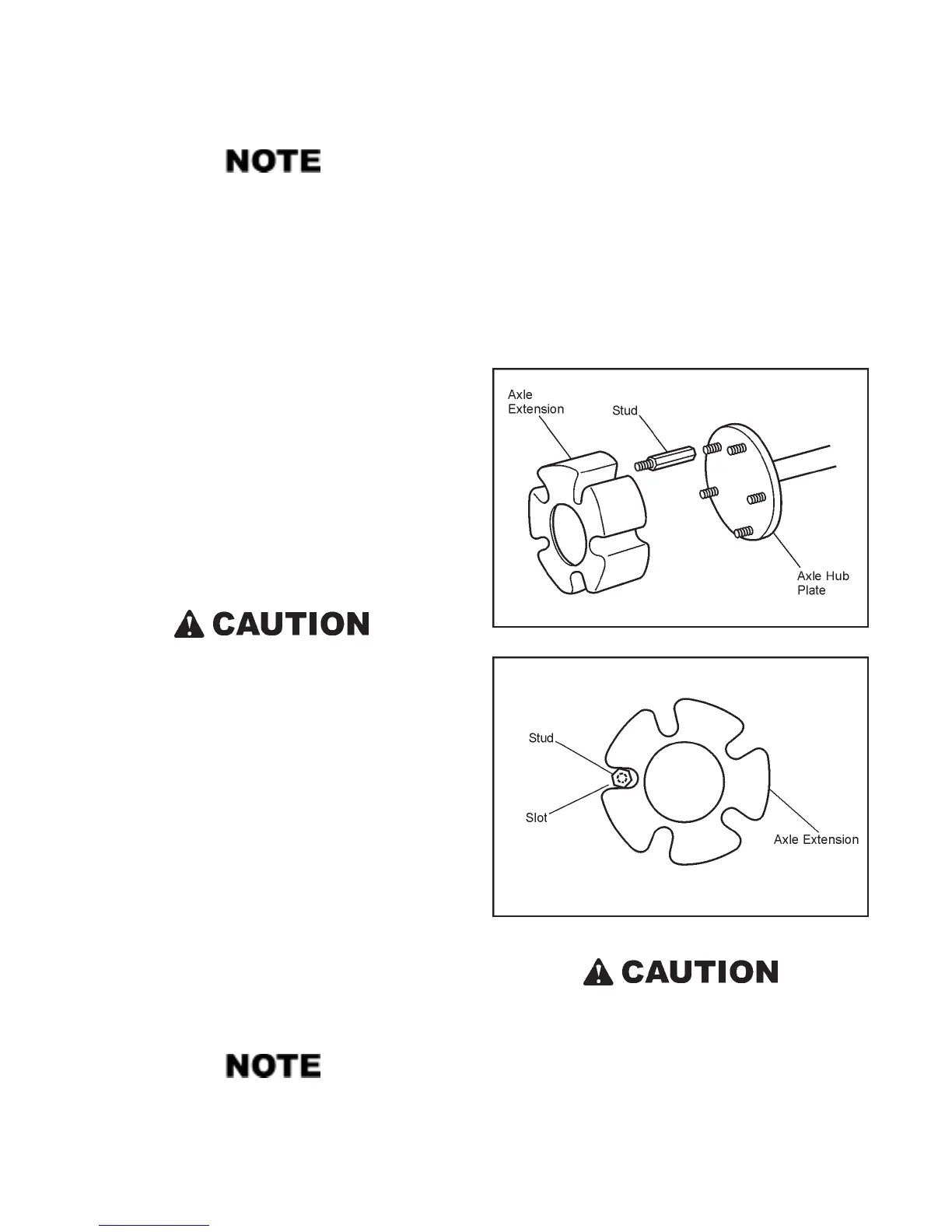

The extension studs have hexagonal sides and must sit

properly within the slots on the axle extension. (See

Fig.11-4) If the extension studs are misaligned with the

slots of the axle extension collar when tightened, ad-

just each stud as necessary by tightening them further

(never by loosening them), until alignment allows for

the extension collar to slide on easily (by hand), up

against the axle hub. Torque to a minimum of 40 ft lbs.

Once the extensions studs are tightened and aligned

correctly, they will not require re-tightening unless they

are removed. However, it is very important that with

the Super Tracks and Rubber Tracks installed, the

wheel nuts of the Argo are tightened to 55 ft. lbs. (75

N.m) initially, re-torqued after the first 10 hours of op-

eration, then again after the next 10 hours, followed

by re-torquing every 25 hours of operation.

Figure 11-3. Installing the Axle Extensions.

Figure 11-4. Check Stud Position in Axle Extension.

Damage to the extension studs, bolts, or axle extension

may occur if the extension studs are not tightened cor-

rectly. Use good judgement when installing.

7. Using a 3/4" socket, install the wheels. Use extreme care

and allow extra installation time to protect the axle exten-

sions from damage. Torque the wheel nuts to 55 ft. lbs.(75

N.m).

Loading...

Loading...