SUPPLY PRESSURE CHECK

.

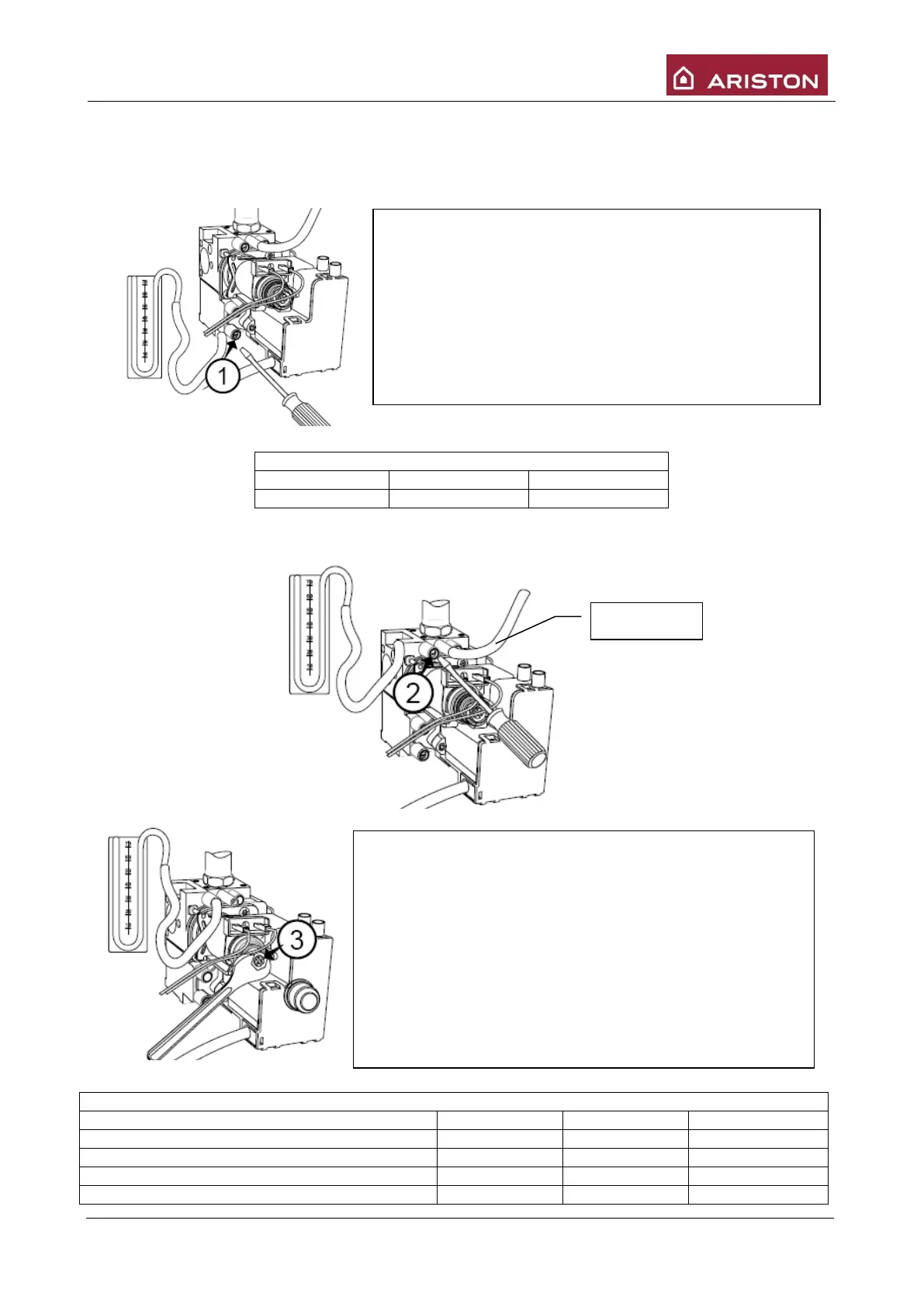

1. Loosen screw “1” (fig. A) and insert the pressure gauge fitting

pipe in the pressure intake.

2. Put the boiler on maximum operating power (hot water tap

open). The supply pressure must correspond with the one foreseen

for the type of gas for which the boiler has been prearranged (refer

to table below).

3. After checking tighten screw “1” and check the seal.

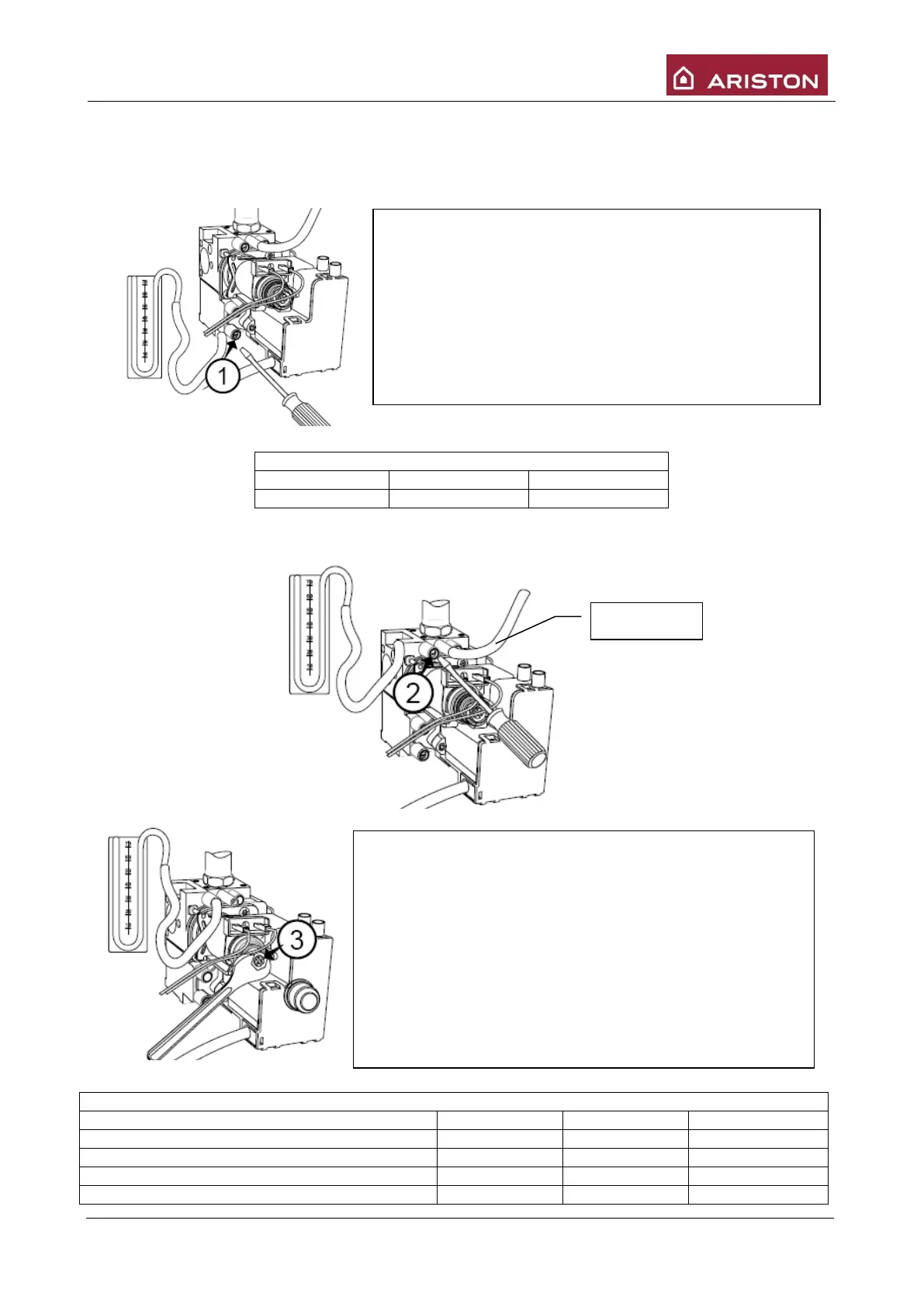

1. To check maximum power, loosen screw “2” (fig.B) and insert the

pressure gauge fitting pipe in the pressure intake.

2. Disconnect the compensation pipe of the air chamber (fig.B).

3. Start the boiler at maximum power with the flue cleaner function

(press Reset button for 5 sec.).

4. The supply pressure must correspond with the one foreseen for

the type of gas for which the boiler has been prearranged (refer to

table below). If it does not, remove the protection cap and act on

adjusting hexagon nut “3” (fig. C).

5. After checking tighten screw “2” and check the seal.

6. Reassemble the protection cap of the modulator.

7. Reconnected the compensation pipe.

Loading...

Loading...