installation &

operating instructions

Design Envelope 4200h & 4280

End Suction Horizontal Pumping Units

34

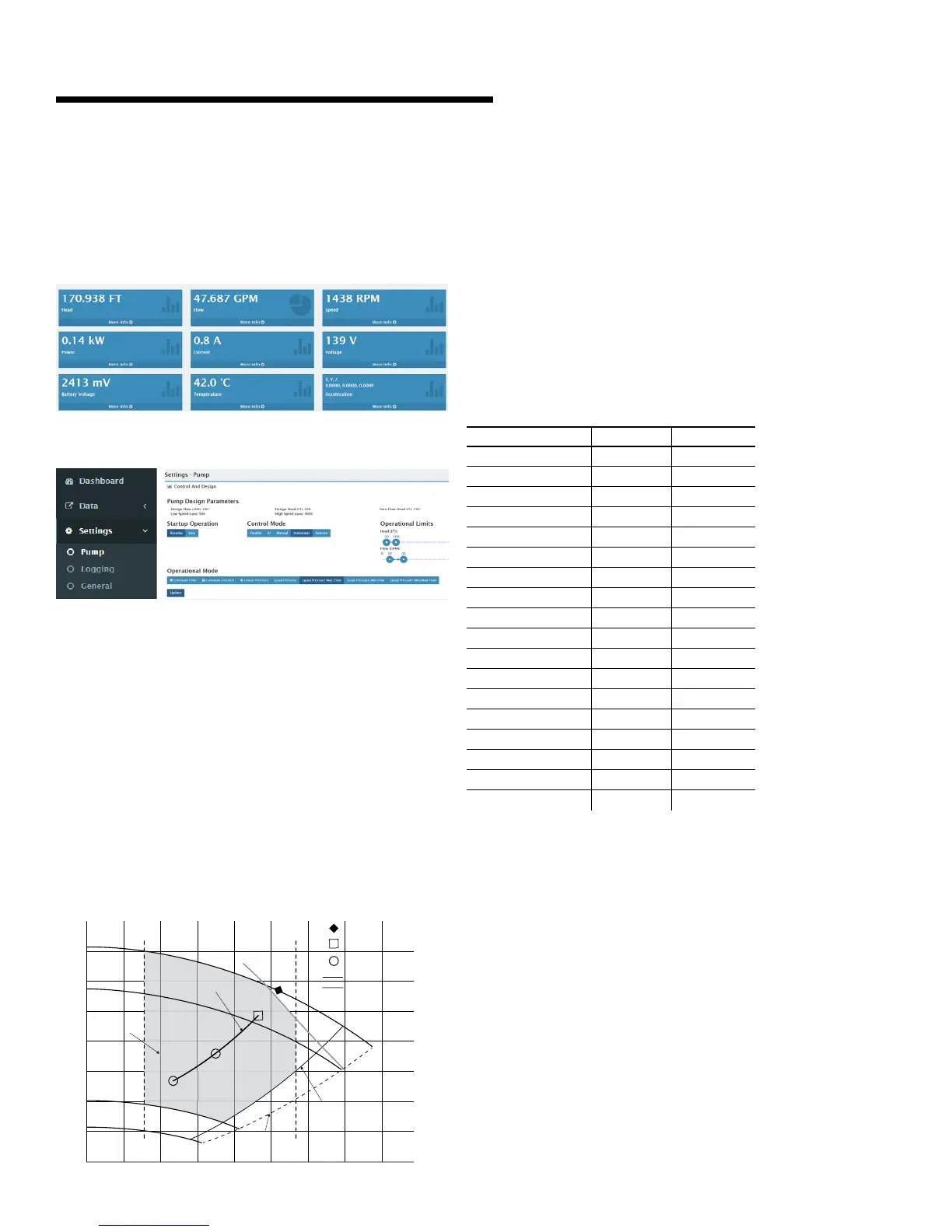

4.4 web interface

At the web browser address bar, type the Pump’s ip (from

Pump’s About screen, Ethernet ip address).

Default user level 1 Password: Armstrong1

To access the control modes:

Press settings Pump

4.5 design envelope flow readout

tolerance

Tolerance on flow and head readings between test stand

instrumentation and Design Envelope controller readout will

be within 5% of bep flow & head values for all Design Envelope

sensorless pump selections.

The same bep flow & head tolerance values will be carried to

the Design Envelope selection point for that model (Guarantee

point, to ansi 40.6 Hydraulic Institute Standard-See fig.4.1),

as follows:

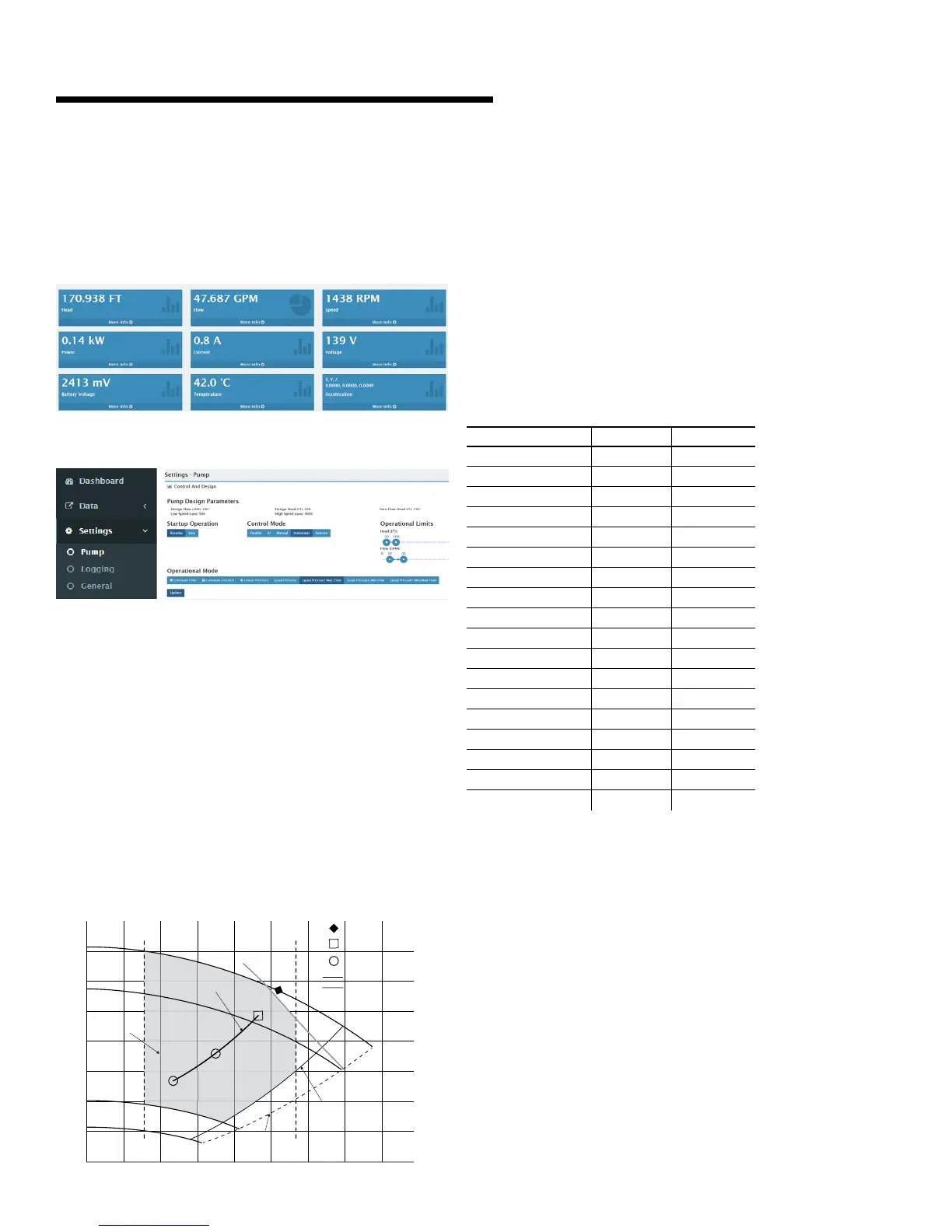

fig. 4.1

The tolerance is applicable when the flow is between 30% and

110% of bep flow at Nominal Pump Speed; and the operating

point is at 54% of Nominal Pump Speed, or greater; and the

motor power is 2hp, or greater.

Flow readouts outside the above limits will be less accurate.

Nominal Pump Speed is displayed as the top speed on any

Design Envelope pump curve.

4.6 noise levels

Motor Maximum Sound Pressure Level

pump model hp [dBA]

1203-001.0 1 69.2

1203-001.5 1.5 72.6

1505-001.5 1.5 62.6

1505H-001.5 1.5 62.6

1505-002.0 2 62.6

1505H-002.0 2 62.6

1505-003.0 3 62.6

1505H-003.0 3 62.6

1505-005.0 5 69.2

1505-007.5 7.5 69.2

0205-001.5 1.5 62.6

0205-002.0 2 62.6

0205-003.0 3 62.6

0205-005.0 5 69.2

0205-007.5 7.5 69.2

2505-003.0 3 62.6

2505-005.0 5 62.6

2505-007.5 7.5 69.2

Sound pressure level measurements made in accordance with iso

3744,± 3dB tolerance (measuring level A-Weighted)

Data based on motor frames at 380-480V. Audible noise is

mainly from the motor fan and will be reduced when operating at

part load.

Quadratic pressure

control curve

BEP

Guarantee &

verification point

Verification point

Head curve

Load limiting curve

End of Envelope

Sensorless Limit

Region of

5% flow & head

accuracy

Minimum speed

Nominal

pump speed

54% Nominal

pump speed

30% BEP flow 110% BEP flow

40% Nominal

pump speed

0

0

10

20

30

40

50

60

70

80

100 200 300 400 500 600 700 800

900

Flow (USgpm)

Quadratic pressure control curve

Head (ft)

Loading...

Loading...