installation &

operating instructions

Design Envelope 4200h & 4280

End Suction Horizontal Pumping Units

36

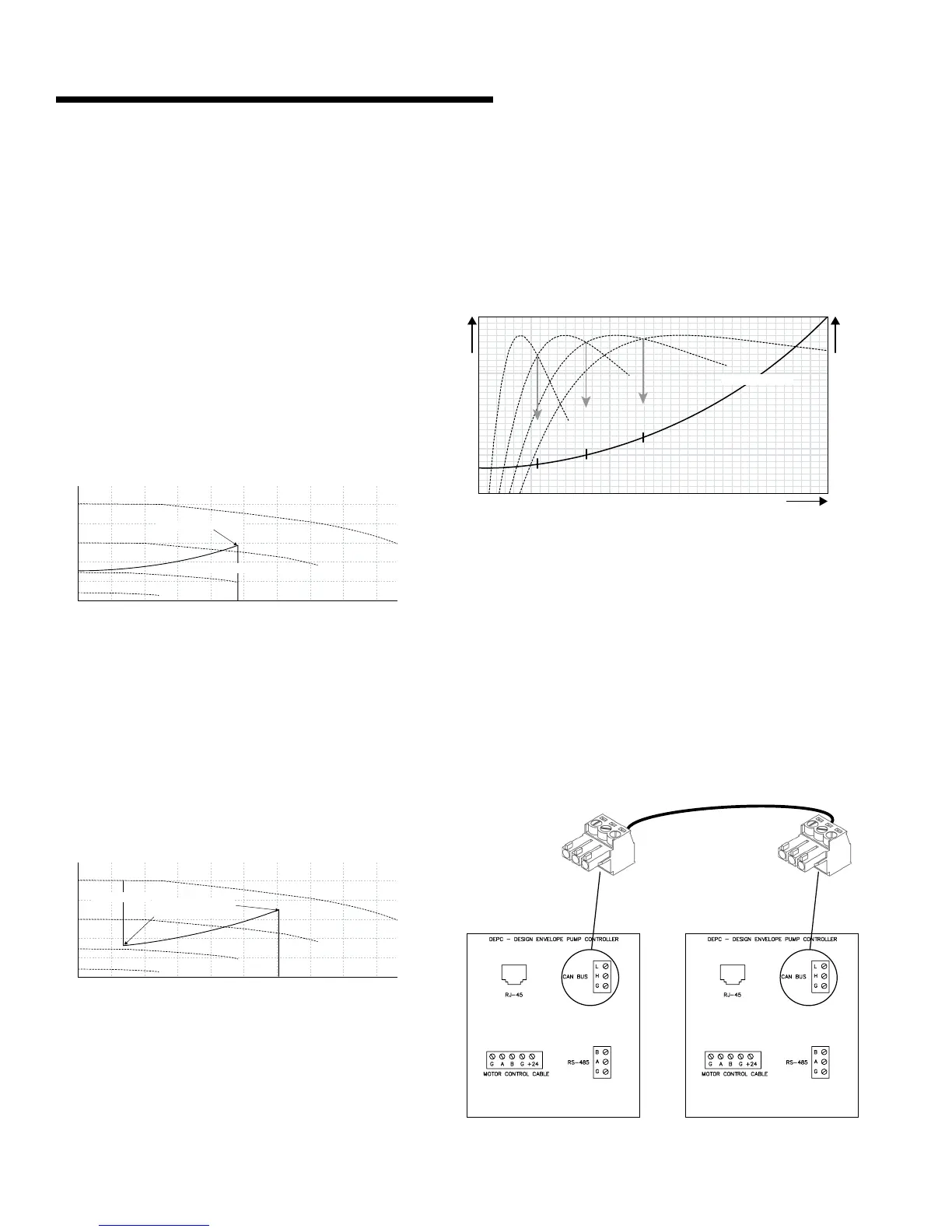

5.6 quadratic curve control with

maximum flow protection

This configuration is ideal for hvac hydronic systems where

pumps are generally oversized and a flow limit is required for

system equipment stability and resulting energy savings. This

control will take advantage of the 5.4 Quadratic Curve Con-

trol mode, where the pump will decrease speed to maintain

a maximum flow setting. This will prevent over-pumping and

save energy costs. Over-pumping is common in hvac systems

as pumps are typically oversized for the application. Pump con-

trols can only control the flow to a minimum speed; thus a dry-

contact relay is supplies which will close when maximum flow

is reached, which can be used for an alarm or other device.

0

0

20 40 60 80 100

200

400

600

800

1000

1200

120 140 160 180

target curve

Maximum Flow Setting

5.7 quadratic curve control with

minimum & maximum flow protection

This control mode combines the control logic of 5.5 & 5.6 which

takes the values of the quadratic control curve and protection

for both the maximum & minimum flow limits. Pump controls

can only control the flow to the motor limit or maximum / mini-

mum speed limits of the unit, thus a dry-contact relay is sup-

plies which will close when either the minimum or maximum

flow is reached, which can be used for an alarm or other device.

0

0

20 40 60 80 100

200

400

600

800

1000

1200

120 140 160 180

target curve

Minimum & Maximum

Flow Settings

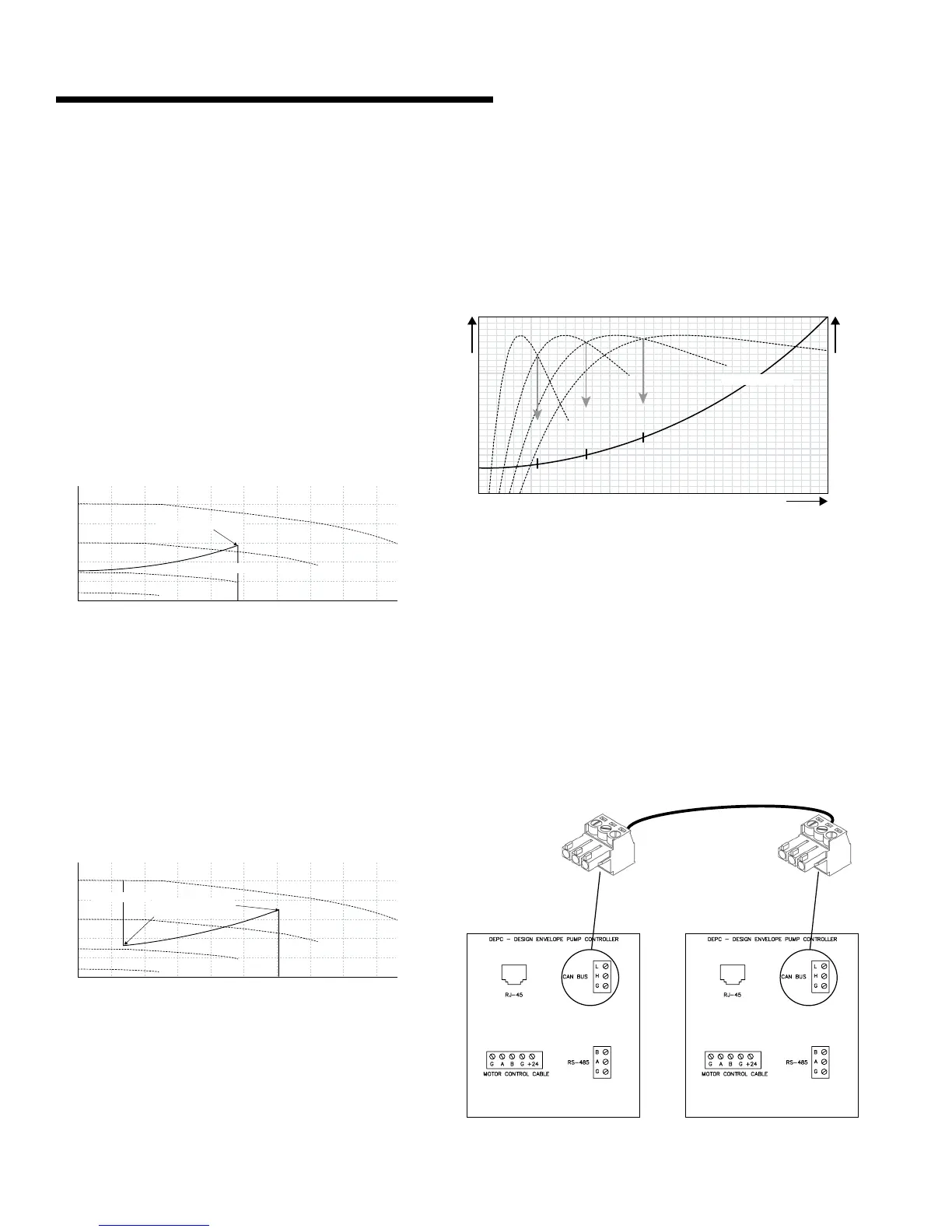

5.8 parallel sensorless pump control

(pspc)

This configuration maps the quadratic control curve into the

pump controls and ensures the system flow requirements are

met, while staging the pumps on and o to maintain optimum

pump energy usage. This is accomplished by operating the

pumping units at the best pumping eciency level for the

required flow.

This control is available for 2, 3, or 4 Design Envelope pump

units operating in parallel. Tango and dualArm units have Paral-

lel Sensorless Pump Control (pspc) pre-programmed in the

controls at Armstrong factories. For all other models (except

twin pumps), pspc can be enabled aftermarket; please contact

your local Armstrong factory for details.

1-pump

1p e 2p e 3p e 4p e

2-pumps

3-pumps

4-pumps

pspc control curve

5.8.1 parallel sensorless pump control for

multiple single pumps

If the Parallel Sensorless Pump Control option was purchased

for control of 2 single pumps (VILs and End Suctions), the func-

tion can be enabled at any time. Note that the pumps must the

same model for proper parallel operation.

Start by installing a wiring bridge between the two pumps (sup-

plied by others). The wiring required between the two control

cards is a CANbus (3-wire) cable with terminal blocks at each

end (3 position strain 3.81mm).

Wiring bridge (supplied by others)

g

g

A = + Positive

B = - Negative

G = Ground

A = + Positive

B = - Negative

G = Ground

From the Webserver, choose Settings -> Pump, set control

mode to Parallel with the following parameter values:

Loading...

Loading...