installation &

operating instructions

Design Envelope 4200h & 4280

End Suction Horizontal Pumping Units

4

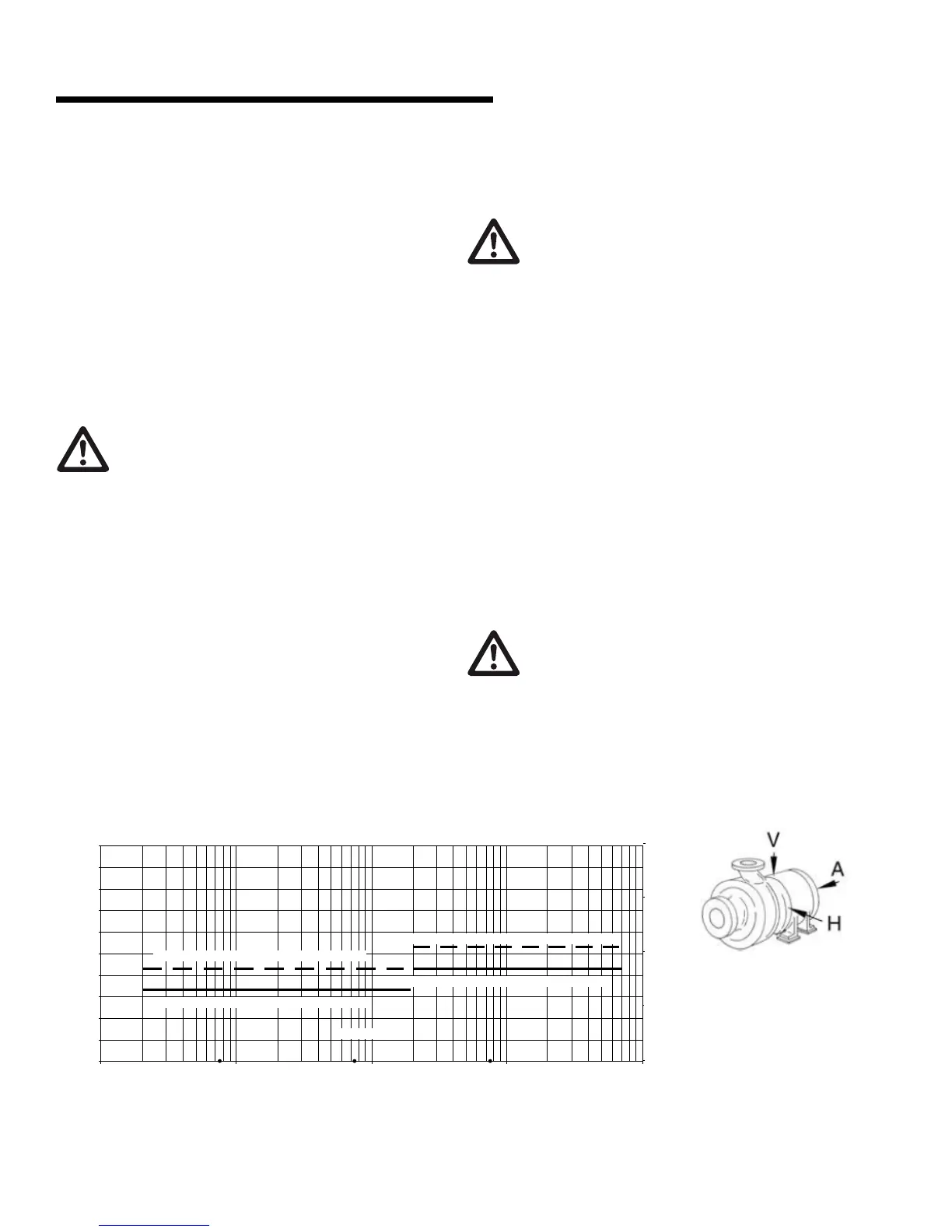

Factory 5.3 mm/s (0.21 in/s) 200 kW (268 bhp) & above

Factory 4.3 mm/s (0.17 in/s) below 200 kW (268 bhp)

Field 3.3 mm/s (0.13 in/s) below 200 kW (268 bhp)

Overall Vibration Velocity (mm/s) RMS

Overall Vibration Velocity (in/s) RMS

Pump power, bhp

Pump power, kW

Field 4.3 mm/s (0.17 in/s) 200 kW (268 bhp) & above

10

101

0

1

2

3

4

5

6

7

8

9

10

100

100

1000

1000 10000

0

0.1

0.2

0.3

0.4

1.0 introduction

This manual contains specific information regarding the safe

installation, operation and maintenance of Armstrong Design

Envelope pumps. Read this manual carefully before installing or

using the product. If clarification is needed on any point please

contact Armstrong quoting the equipment serial number.

1.1 precautions

1.1.1 instructions for safe use

No installation of this equipment should take place

unless this document has been studied and under-

stood. Handling, transportation and installation of this

equipment should only undertaken by trained personnel with

proper use of lifting equipment. See later diagrams for lifting

advice. Refer to the pump nameplate for pump speed, pressure

and temperature limitations. The limits stated must not be

exceeded without written permission from Armstrong.

1.1.2 ambient temperature

Install the Design Envelope unit with adequate access

for routine maintenance. A minimum of 2" (50 mm)

clearance is required at the fan inlet to facilitate

airflow. Where several Design Envelope units are installed in

close proximity, care must be taken to ensure that there is no

re-circulation of exhausted warm air.

Under normal operating conditions the pump surface tempera-

ture may reach 68°c/ 155°f (Restricted Zone) to 80°c/176°f

(Unrestricted Zone). Steps should be taken to minimize contact

or warn operators/users that normal operating conditions will

be exceeded. in certain cases where the temperature of the

pumped liquid exceeds the above stated temperature levels,

pump casing temperatures may exceed 100°c/212°f and not

withstanding pump insulation techniques appropriate mea-

sures must be taken to minimize risk for operating personnel.

The ambient temperature for standard motors must be no

greater than 40°c/104°f.

1.1.3 enclosure rating

The standard enclosure rating for Design Envelope

4200H and Design Envelope 4280 integrated

controls is ul Type 12 / ipp55. If the pump is to be

installed in a wet or dusty environment, then a higher enclosure

rating may be required (contact Armstrong).

1.1.4 vibration levels

Armstrong end-suction horizontal pumps are designed to meet vibration levels set by Hydraulic Institute Standard hi Pump

Vibration 9.6.4. Standard levels are as detailed below

Loading...

Loading...