installation &

operating instructions

Design Envelope 4200h & 4280

End Suction Horizontal Pumping Units

40

note:

Snug fit the coupling screws and confirm even gap spacing

between coupling halves, then firmly tighten coupling screws

following the tightening pattern illustrated. Then push (or slide)

mechanical seal (62) firmly onto the stationary seat (61) and

tighten the set screws (62A) by a torque wrench to 5 (ft. lbs).

The mechanical seal is now pre-set at the correct working

length.

j Replace the seal flush piping (59) and drain plug(s). Open

all isolating valves prior to operating pump(s). Reconnect

power supply.

6.3.2 mechanical seal replacement instruc-

tions for close-coupled pumping units

(series 4380, 4280 & 4372)

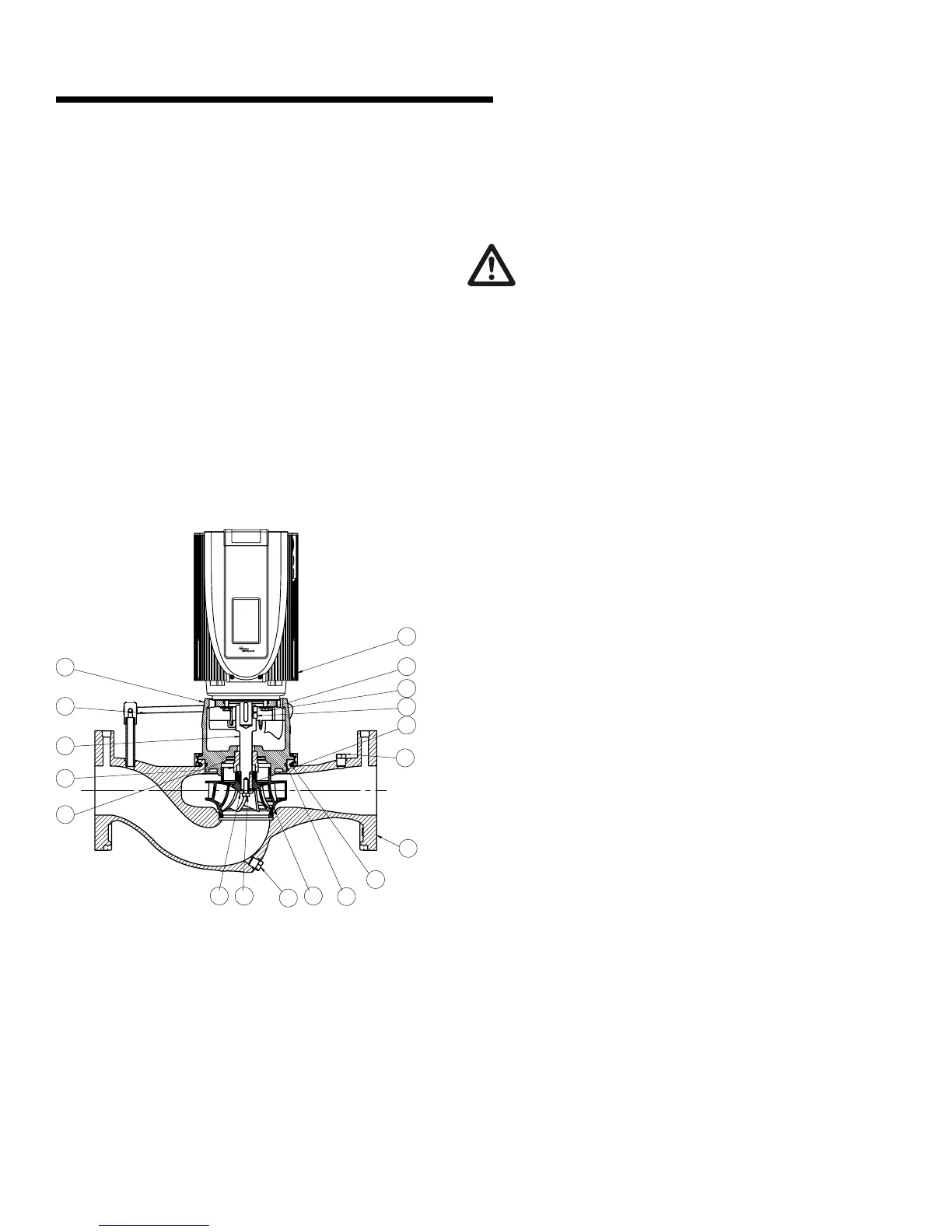

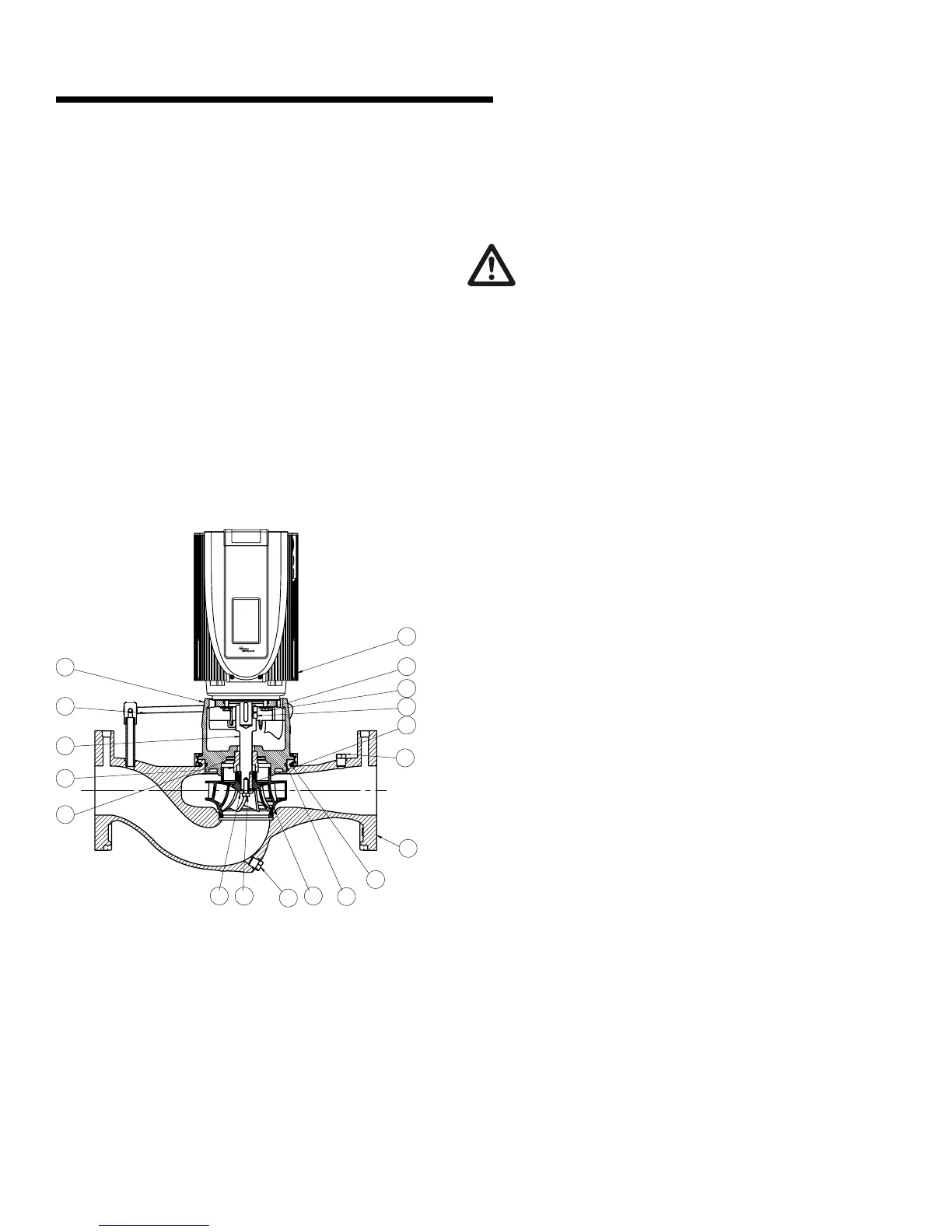

80

101

86

83

16

36

35

94

21

40

10

43

44

59

62

102

100

61

The close-coupled or motor mounted type Vertical in-Line

pumps use vertical shaft-down ball bearing motors (integrated

motors and drives). Each pump and motor unit is pipe mounted

and as such relies on the piping only for support. The piping

support is designed for the weight of the piping, liquid, pump

and motor and other pipe fittings. The pumping unit should not

be independently secured to the building structure. If the pump

is mounted separately to any structure, the pump must be iso-

lated from the piping with flexible piping connections. For units

with larger motors it is advisable to install a permanent device

for lifting the rotating assembly out of the pipe mounted casing

to service the unit.

Breakdown procedures:

caution

Exercise extreme care when handling power wiring.

Ensure that the fuses are removed or breaker discon-

nected in the power line to the motor. Power discon-

nect should be within sight of the pump being serviced and

tagged with the reason for disconnection.

a Electrical wiring

If the pump and/or motor assembly is to be serviced on a

bench, the motor wiring must be disconnected.

b Isolation valves

If the system is not drained: Ensure that the suction and dis-

charge piping isolation valves are closed. Remove drain plug

(35) from the bottom of the casing and drain the pump.

c Prepare assembly for removal

Secure the motor (10) by lifting straps to an overhead chain

fall or similar lifting device. The device must be designed to lift

the weight of the unit safely. Raise the lifter to bring the lifting

straps taut. Disconnect the flush/vent flex hose from pump

suction and secure flex hose to one side. Remove the clamp

ring between casing (100) and adapter (40). Care should

be taken not to apply pressure to the outside diameter of the

adapter, to prevent possible breakage, outside pressure should

be on the casing only.

d Remove rotating assembly

The rotating assembly [motor, adapter and impeller] (10, 40 &

80) may now be lifted out of the casing.

e Rotating assembly notes

The impeller (80) is fastened directly to the stub shaft and

must be removed to replace the mechanical seal assembly

(61/62). This may be accomplished on a safe surface near the

installation, or more conveniently on a work bench.

f Impeller cap screw

The impeller (80) should be prevented from rotating while the

impeller cap screw (86) is loosened. A heavy screwdriver or

pry bar may be inserted in between the impeller blades to en-

able the impeller cap screw (86) to be backed o with a socket

wrench [note: be careful not to damage the impeller blades].

Remove the impeller cap screw and washer (86 & 83).

g Pump impeller

Using wheel pullers, with the jaws behind the rear shroud of

the impeller (80) [Behind a vane at each side] pull the impeller

free of the pump shaft. Impeller that is dicult to remove may

be loosened by heating the impeller hub with a torch during the

pulling process to remove the impeller from the motor shaft.

Loading...

Loading...