installation &

operating instructions

Design Envelope 4200h & 4280

End Suction Horizontal Pumping Units

39

6.3.1 mechanical seal replacement instruc-

tions for rigid split- coupled pumping

units (series 4300, 4200h & 4322)

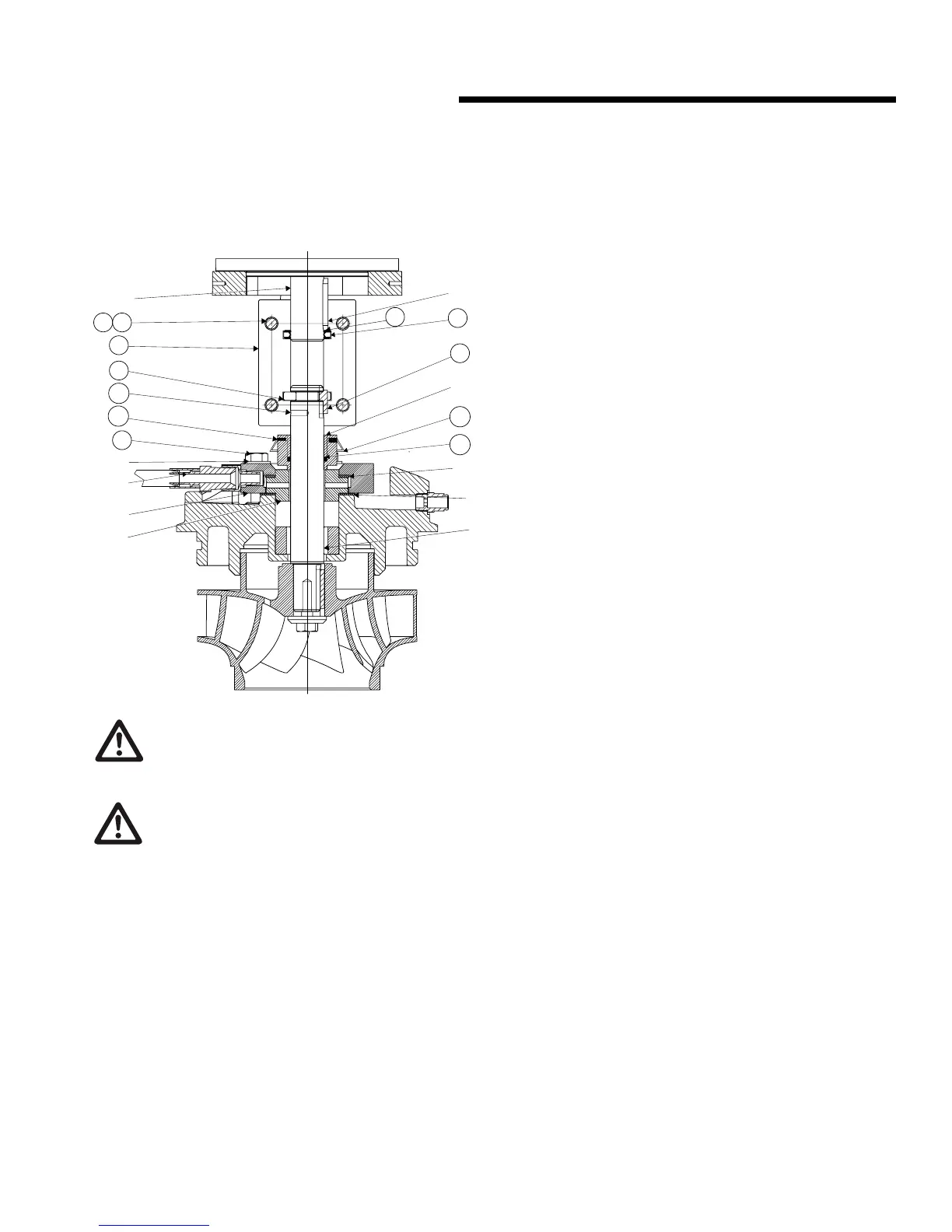

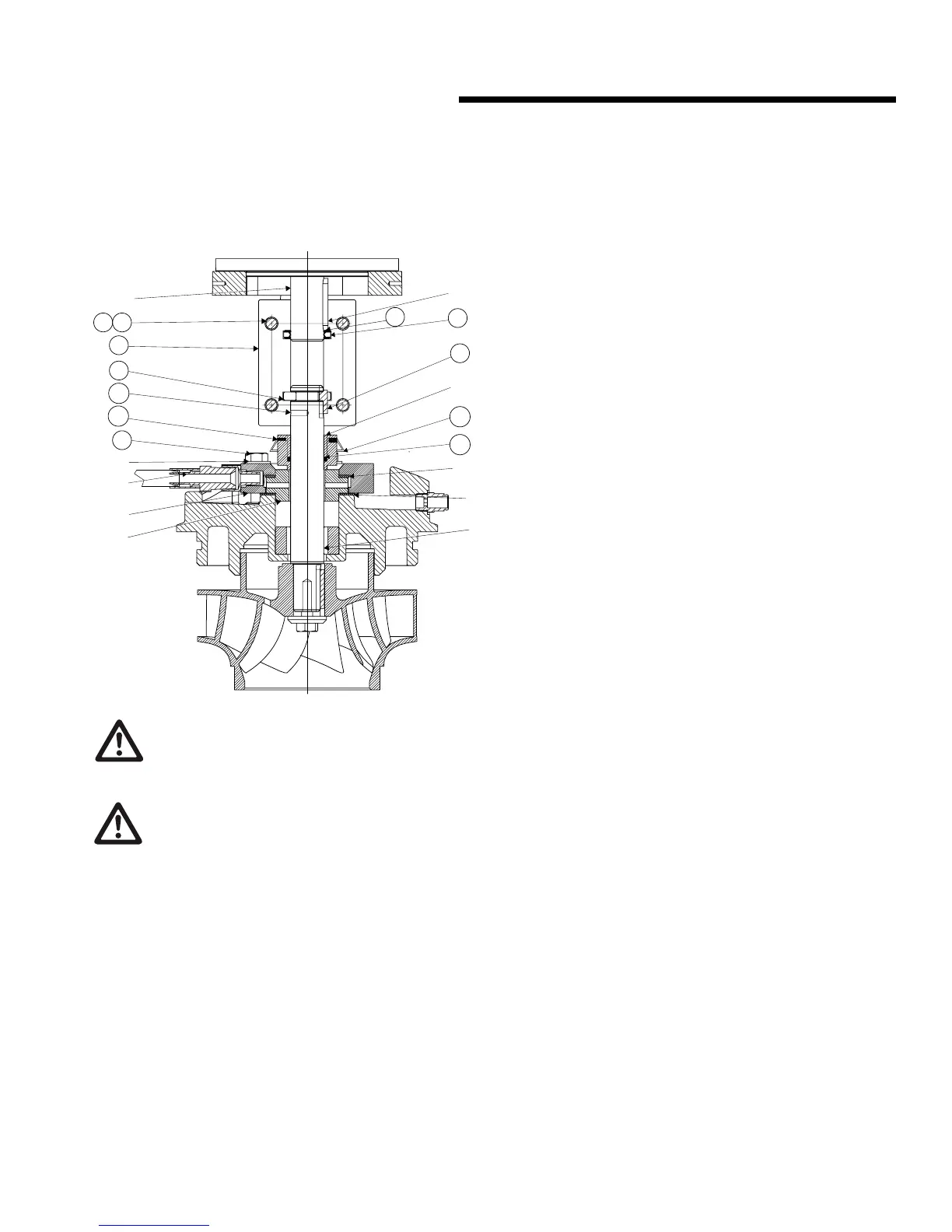

1

4

1

9

5

5

6

5

6

5

0

2

2

3

140

148

21A

62C

62B

62A

145

155

156

149

163

caution

Do not use oil, Vaseline or other petroleum or silicon

based products for seal elastomer lubrication.

Otherwise elastomer swelling may occur, causing seal

failure. Recommended: International Products Corp p-80

Rubber Lubricant Emulsion in USA & UK www.ipcol.com

Seal Removal

An important feature of the rigid split-coupled pump is that the

design permits removal of the mechanical seal without disturb-

ing the pump, motor or electrical wiring.

a Disconnect the power supply at the main switch and close

the isolating valves on the suction and discharge. Empty

casing by removing drain plug(s) located at the bottom.

b Loosen o the seal collar set screws (62A) Remove the

coupling screws and lock washer (144,145) and separate

the coupling halves (140). Remove the motor shaft key

(05) and the pump shaft key (149).

Do not remove motor collar (155) for seal replacement.

c Remove the mechanical seal rotating assembly (62)

through the gap between the pump and motor shafts..

d Disconnect the seal flush piping (59) from pump discharge.

Mark seal gland plate (54) position. Remove the seal gland

plate bolts and washer (lock washer) (52,163) and seal

gland plate (54). Remove the stationary seat (61) and seat

gaskets (55).

Seal replacement

Handle mechanical seal carefully to protect seal faces from

damage. Do not contaminate seal faces with finger prints

e Replace the stationary seat (61) and gaskets (55) from

mechanical seal package, aligning the seat flush hole with

the seal gland plate flush line connection. Ensure the large

diameter gasket is on the bottom. Replace seal gland plate

(54) and tighten the seal gland plate bolts (52,163) evenly

and diagonally to 5 (ft. lbs) for 0.75" seal size.

f When installing the mechanical seal (62), ensure parts are

perfectly clean.

g Apply a small amount of temporary rubber lubricant emul-

sion to the O-ring (62b). Carefully slide the mechanical seal

rotating assembly (62) down the shaft onto the stationary

seat (61). Do not tighten the set screws (62a) on the side

of the mechanical seal yet. Do not remove holding clips

(62c).

If motor is replaced: Loosen set screws (56) on motor shaft

collar (155) and remove from old motor shaft. To position the

collar (155) correctly on the new motor shaft, temporarily

fit motor shaft collar (155) into groove of the keyed coupling

half. Slide collar, with coupling half onto new motor shaft until

end of shaft lines up with line scored into coupling. Tighten

the visible set screws (156) in the collar (155) enough to hold

the collar in place on the shaft and remove the coupling half.

Tighten all collar set screws (156) evenly and diagonally.

h Fit the motor shaft key (05) and the pump shaft key (149)

then install the keyed coupling half (140) first.

note:

For easier coupling installation, motor and pump shaft keys (05

& 149) should be 180 degrees from the working area. To auto-

matically locate the impeller in the pump, insert the coupling

screw Allan wrench into positioning hole (21a) and lift pump

shaft until the pump shaft collar is positioned in the coupling

groove, then rotate shaft to locate the pump shaft key (149)

into blind keyway in coupling.

i Place the second coupling half into position and tighten the

coupling screws (144,145) following the tightening pattern

shown on the illustration (1-2-3-4).

warning

When reinstalling the clamp, tighten the clamp nut to

90-100 in-lb torque.

Loading...

Loading...