installation &

operating instructions

Design Envelope 4200h & 4280

End Suction Horizontal Pumping Units

42

t Conduit Box Cover

The conduit box cover is replaced after checking the motor ro-

tation. The pump may now be placed in operation.

6.4 system cleanliness

Before starting the pump, the system must be thoroughly

cleaned, flushed and drained and replenished with clean liquid.

Welding slag and other foreign materials, Stop Leak and clean-

ing compounds and improper or excessive water treatment are

all detrimental to the pump internals and sealing arrangement.

Proper operation cannot be guaranteed if the above conditions

are not adhered to.

7.0 warnings and alarms

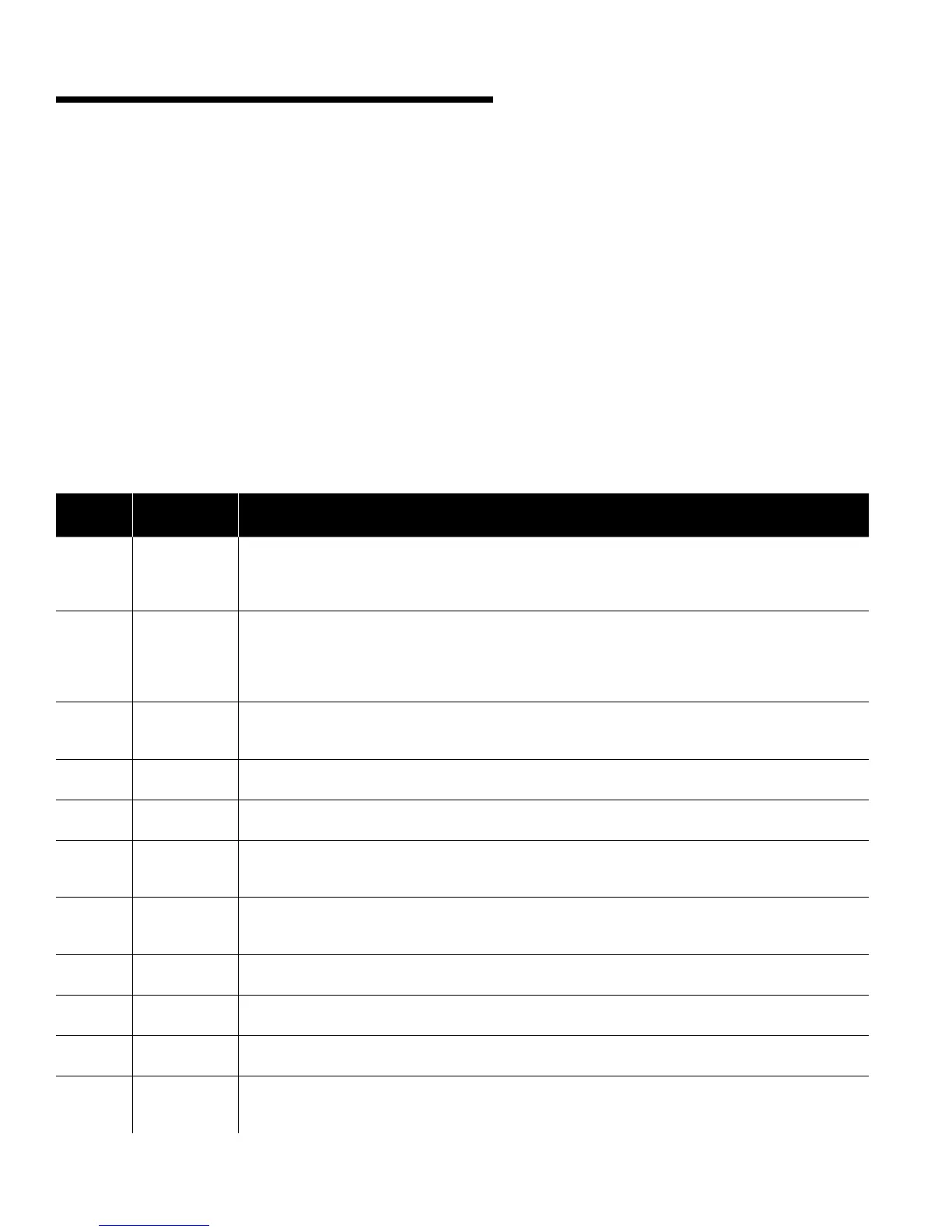

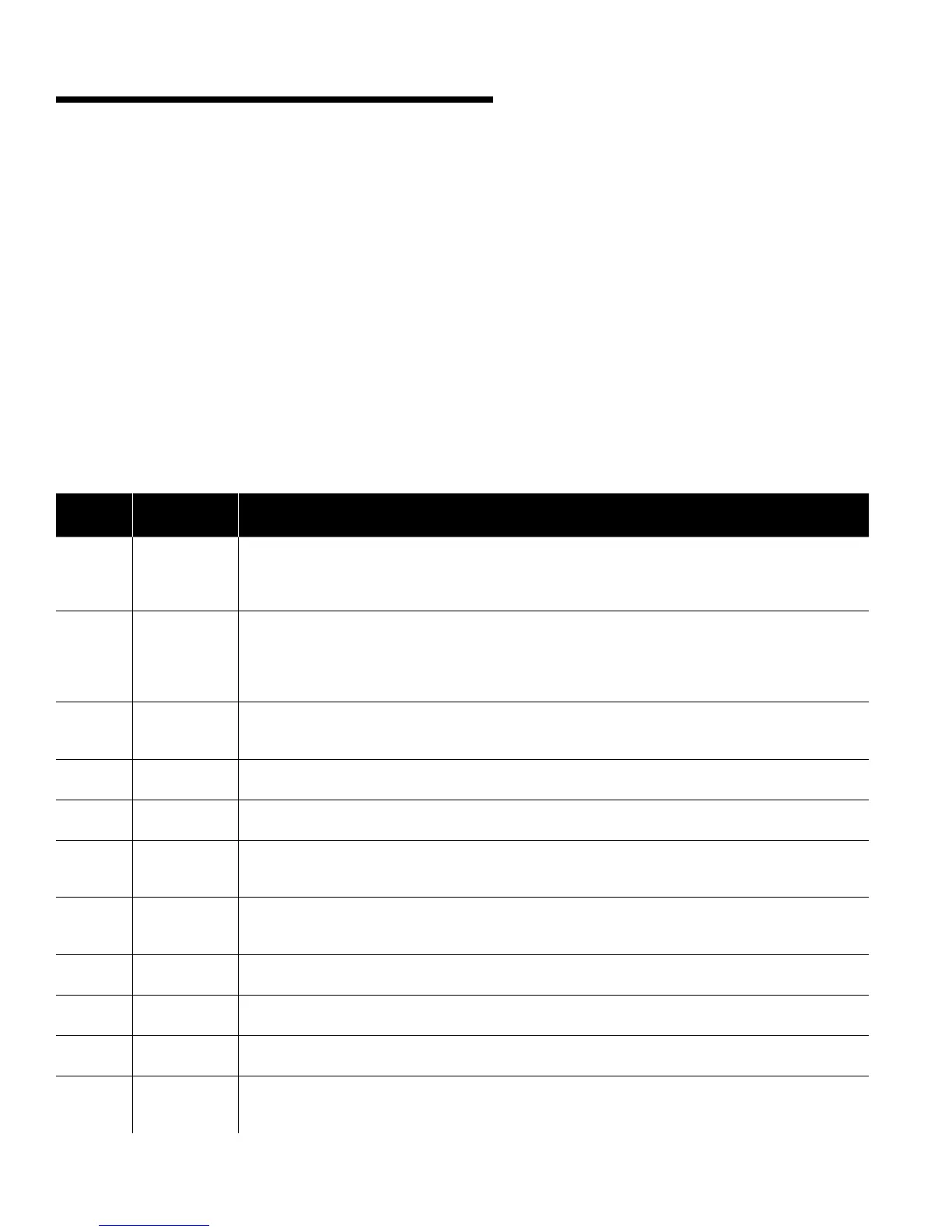

7.1 alarm summary for interfaces

alarm

number

name alarm description

1 vsd over

temperature

The temperature of a vsd or motor component is exceeding the thermal alarm limit. Turn o the power

to the pump and verify that the motor, fan and vsd cooling is functioning correctly. Verify that the pump

is not overloaded. Wait until hot components have cooled before returning to service and if the alarm

persists after powering up contact an Armstrong Technical Service representative.

2 vsd over

current

The vsd has detected current exceeding the safe limit. Turn the pump o. (If there is a discharge from the

output phases to earth it can be verified by checking for any faults with a megohmmeter between ground

and the motor leads). If a current limit has been exceeded in the vsd check that the motor can be turned.

If the pump is being overloaded reduce the pump speed using hand mode control. If the alarm persists

after powering up contact an Armstrong Technical Service representative.

3 External vsd

voltage

The voltage into the vsd is out of range. Verify that the correct voltage required to operate the vsd is

present by measuring each of the 3 phases. If the alarm persists after cycling power to the pump, contact

an Armstrong Technical Service representative.

4 Internal vsd

voltage

An internal voltage generated by vsd is out of range. If the alarm persists after cycling power to the

pump, contact an Armstrong Technical Service representative.

5 Internal vsd An internal error in the vsd has occurred. If the alarm persists after cycling power to the pump, contact

an Armstrong Technical Service representative.

6 vsd parameter One or more of the parameters to control the vsd are not correct. Check the settings on the control

card. If the alarm persists after cycling power to the pump, contact an Armstrong Technical Service

representative.

7 vsd startup An error occurred during the startup of the motor. Turn o the power to the pump and verify that the

motor can be turned by using hand mode control. If the alarm persists after powering up contact an

Armstrong Technical Service representative.

8 Other vsd There has been an unknown alarm condition generated by the vsd. If the alarm persists after cycling

power to the pump, contact an Armstrong Technical Service representative.

9 vsd

communication

There is a communication issue between the control card and vsd. Turn o the power to the pump and

check the connections between the control card and the vsd.

10 vsd speed The speed set by the vsd is not within tolerance. If the alarm persists after cycling power to the pump,

contact an Armstrong Technical Service representative.

11 vsd

initialization

failure

The control card was not able to receive the initial parameters correctly. Please try to restart the pump. If

the alarm persists after restart, contact an Armstrong Technical Service representative.

Loading...

Loading...