installation &

operating instructions

Design Envelope 4200h & 4280

End Suction Horizontal Pumping Units

6

important:

Do not run the pump for any length of time under very

low flow conditions or with the discharge valve closed.

To do so could cause the water in the casing to reach

super heated steam conditions and will cause premature failure

and could cause serious and dramatic damage to the pump and

surrounding area.

1.2 mechanical installation

1.2.1 location

in open systems, locate the unit as close as practical to the

liquid being pumped, with a short, direct suction pipe. Ensure

adequate space is left above and around the unit for operation,

maintenance, service and inspection of parts.

in closed systems, where possible, the pumps should be

installed immediately downstream of the expansion tank /

make-up connection. This is the point of zero pressure change

and is necessary for eective pump operation. Do not install

more than one expansion tank connection into any closed

hydronic system. Electric motor driven pumps should not be

located in damp or dusty location without special protection.

Airflow into the motor and/or motor fan should not be

obstructed.

It is good practice to leave sucient space around equipment

for maintenance and service needs. If the Design Envelope

controls are supplied with integral disconnect switches,

3 6"/ 1 meter clearance may be required in front of the controls

to meet local electrical codes.

1.2.2 installation

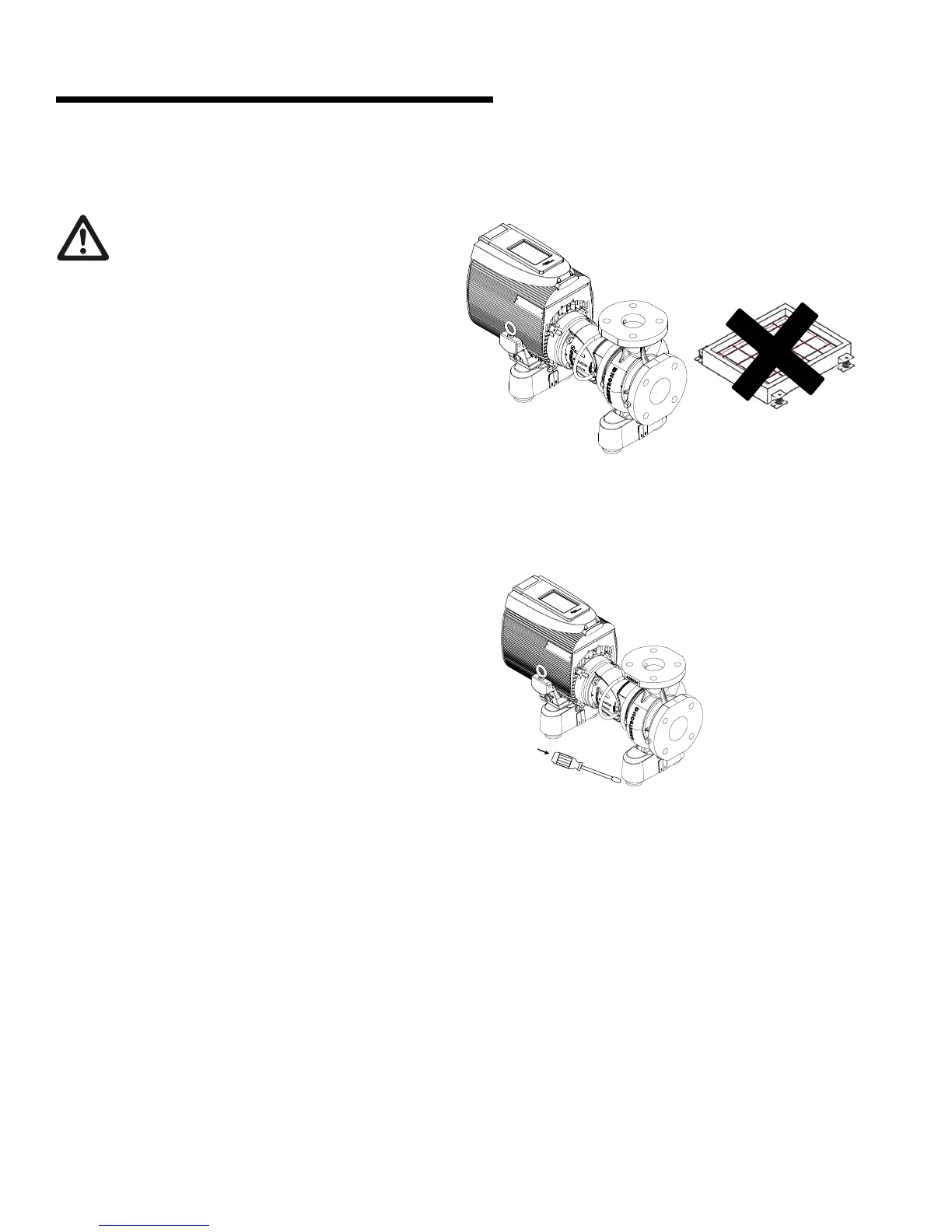

The Design Envelope 4200h and 4280 pumping units 1-10hp

are equipped with integral vibration isolators and do not re-

quire inertia bases or baseplates for horizontal (shaft orienta-

tion), base-mounted installations. The vibration isolators are

pre-sized for the pumping unit and will reduce the transmission

of noise and vibration from the pump and piping system to the

building structure.

fig 1.2.1

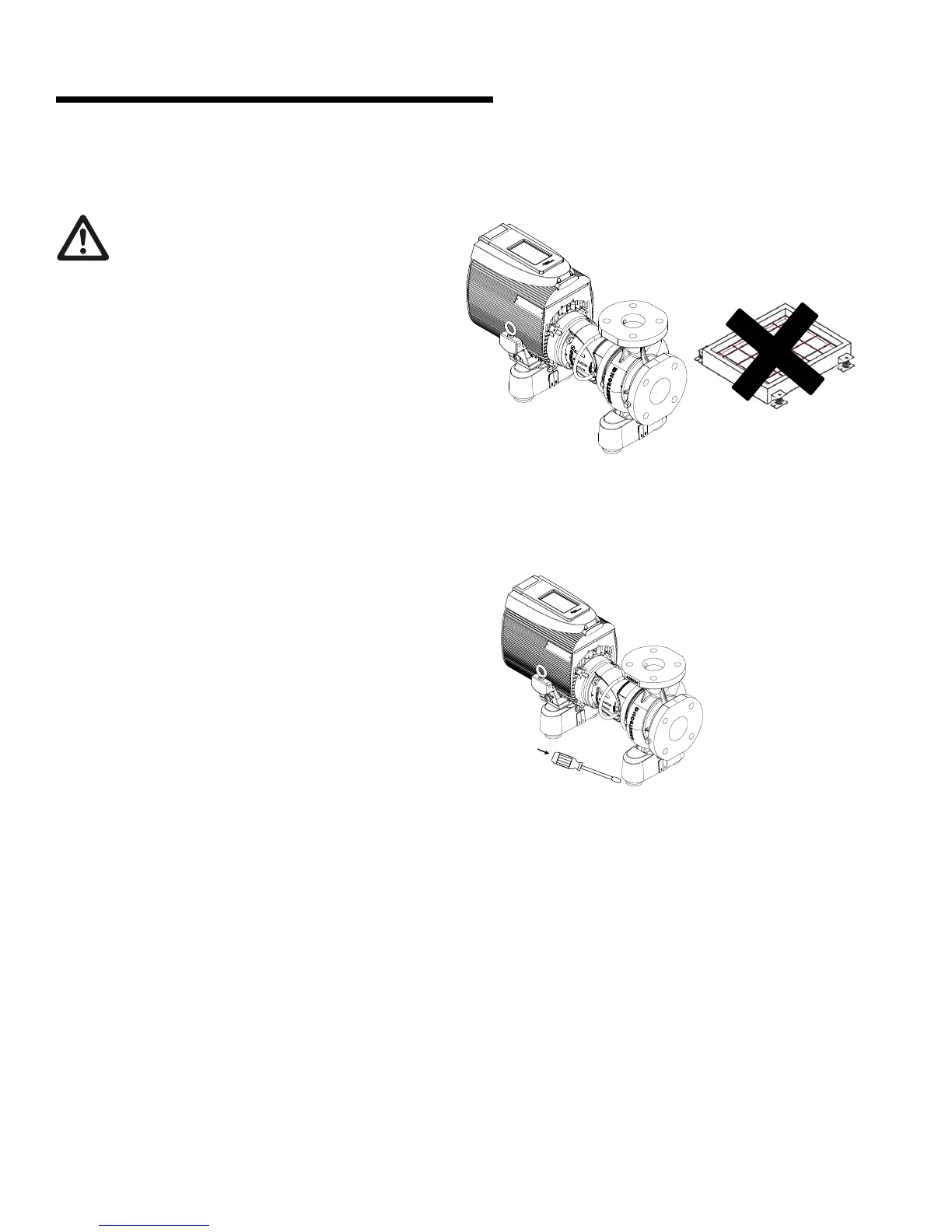

The springs use anti-friction neoprene cup mounts and prevent

lateral movement of the pump. If accurate positioning of the

spring cups is required, gently use a tool, such as the end of a

flat-head screwdriver (or crowbar) to tap the cups into place.

fig 1.2.2

Loading...

Loading...