installation &

operating instructions

Design Envelope 4200h & 4280

End Suction Horizontal Pumping Units

8

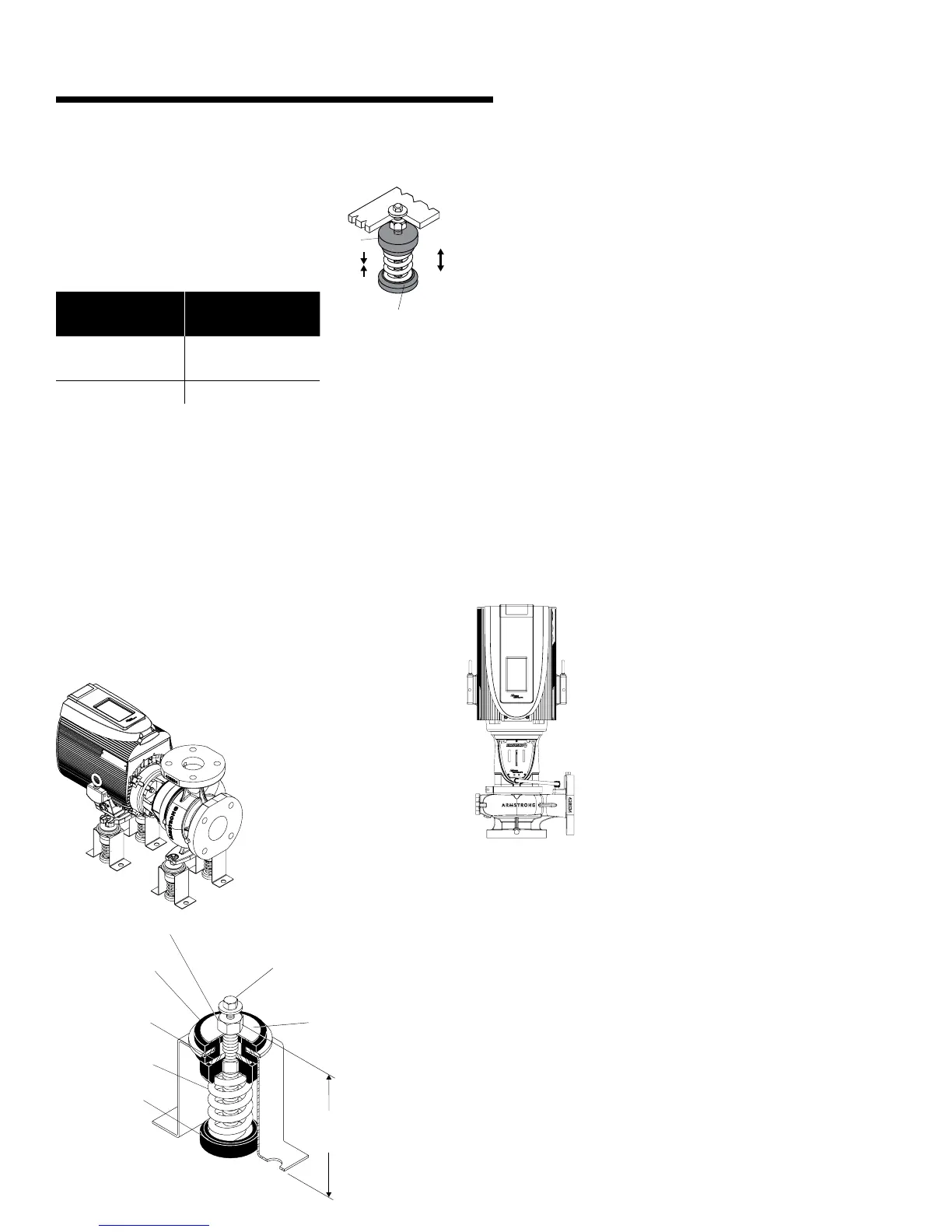

Turn the cast knob clockwise to increase

the free & operating height, or counter-

clockwise to decrease the height. The free

& operating heights by pump model are

listed in the below table

de 4200h/4280,

spring type

free & operating

height

Standard Spring

Isolators

3.75" (95 mm)

Seismic Mount 5.00" (127 mm)

The shrouds can then be re-assembled to the pump by

fastening the 2 halves together around the pump foot and

motor foot. Push the shroud assembly down and ensure the

shroud pins click into the locator holes in the castings.

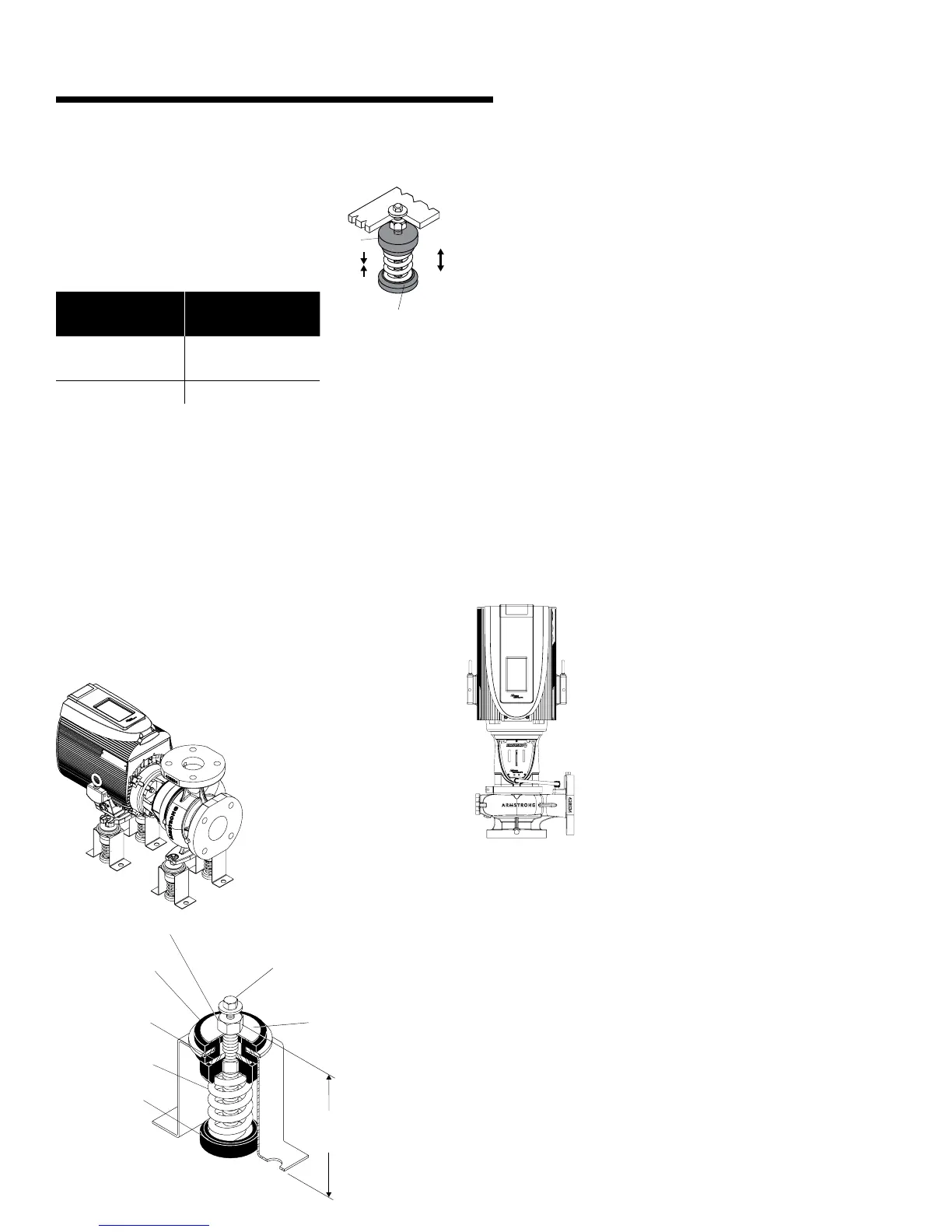

1.2.6 installation for seismic mounts

Pumps equipped with the Seismic Mount option have seismic

mounts factory pre-installed to the feet and must be bolted

to the ground structure. Anchor rods may be either cast-in

place or post-installed. Ensure the anchoring and mounts are

installed along the long side of the pump (as shown in

fig 1.2.6)

fig 1.2.6

¼" × 1" (25mm)

locking cap screw

height

down stop

adjustment bolt

all-directional

neoprene snubber

upward rebound

plate is adjustable

interchangeable

steel spring

neoprene

acoustical cup

Take 2 full counter-clockwise turns on each leveling bolt and

continue even adjustment of all mounts until all springs are

loaded and mountings are back to Free and Operating Height.

Take no more than two additional counter-clockwise turns on

any leveling bolt to level equipment.

Tighten cap screws to secure equipment.

Adjust plates so there is V" (3mm) clearance between top

of plate and underside of all-directional neoprene cushion. Turn

rebound plates clockwise to lower, or counter-clockwise

to raise.

1.2.7 vertical shaft installation

Design Envelope 4200h and 4280 pumping units 1-10hp may

be safely installed in a vertical shaft orientation as shown in fig

1.2.7. The motor fan must be in an upright position; with the

suction port facing down. When installed vertically, the integral

springs and shrouds should be removed from the base of pump.

fig 1.2.7

1.2.8 pump piping – general

Never connect a pump to piping, unless extra care is taken to

measure and align the piping flanges well. Always start piping

from pump.

Use as few bends as possible and preferably long radius

elbows.

Ensure piping exerts no strain on pump as this could distort

the casing causing breakage or early failure due to pump

misalignment.

All connecting pipe flanges must be square to the pipework and

parallel to the pump flanges.

Turn

cast knob

cw=

ccw=

acoustical cup

Loading...

Loading...