Ascon Tecnologic - X34 - OPERATING INSTRUCTIONS - PAG. 8

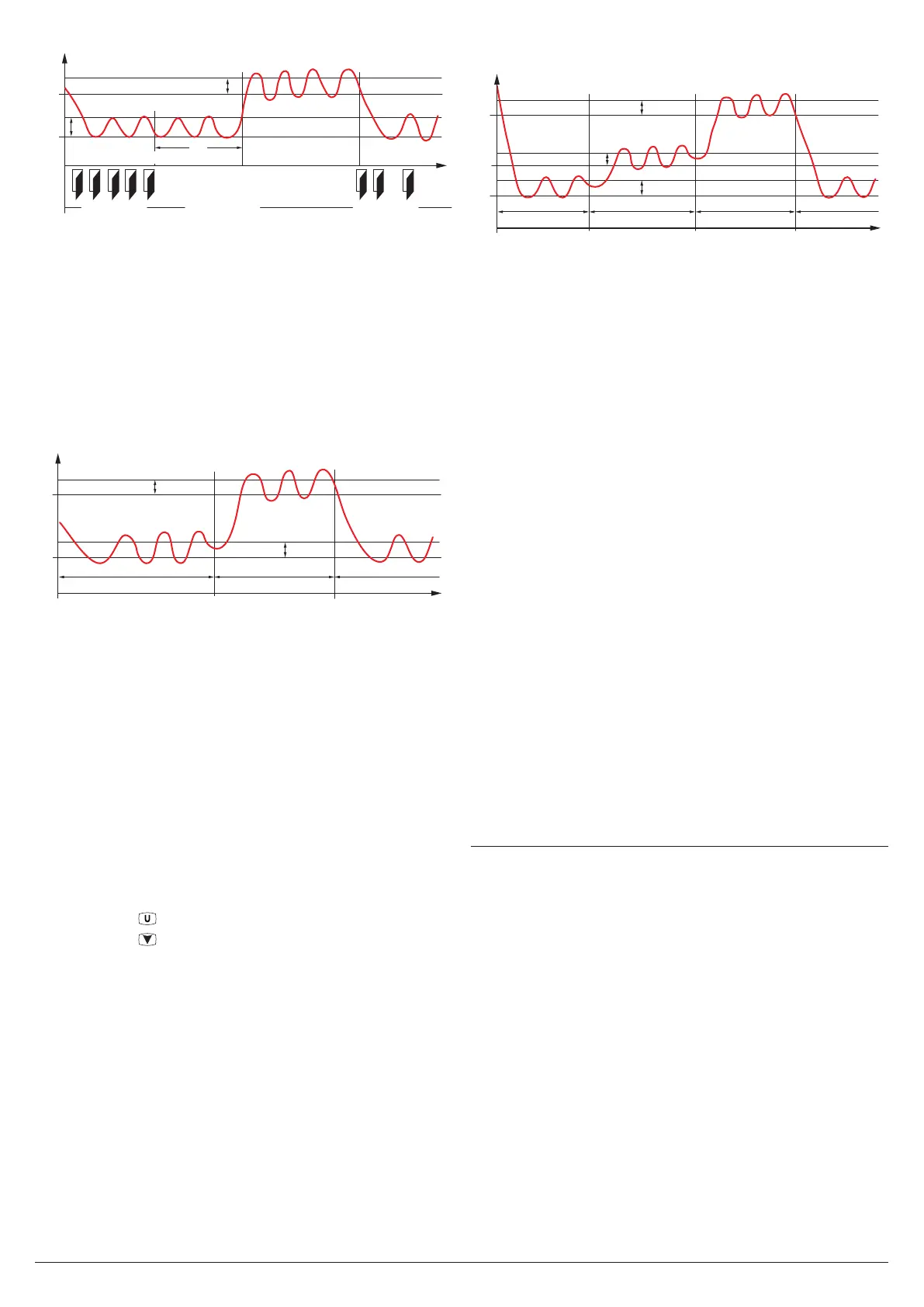

Pr1

SPE

SP

Door

r.d

r.Ed

i.Et

time“Norm.”

DAY (Shop open) DAY (Shop open)NIGHT (Shop closed)

“Norm.” “ECO”

Example of automatic switching between Eco mode and

Normal mode. During working hours the door is frequently

opened and the controller remains in Normal mode. When

the door has not been opened for time i.Et, the control-

ler switches to Eco mode. As soon as the door is opened

again, the controller reverts to Normal mode.

This function requires use of a digital input configured as

i.oF = 1, 2 or 3 (door open input)

If i.Et = oF the Eco/Normal mode selection via the digital

input configured as door, is deactivated.

If i.tt = oF the Eco/Normal mode switching due to time-out

is deactivated.

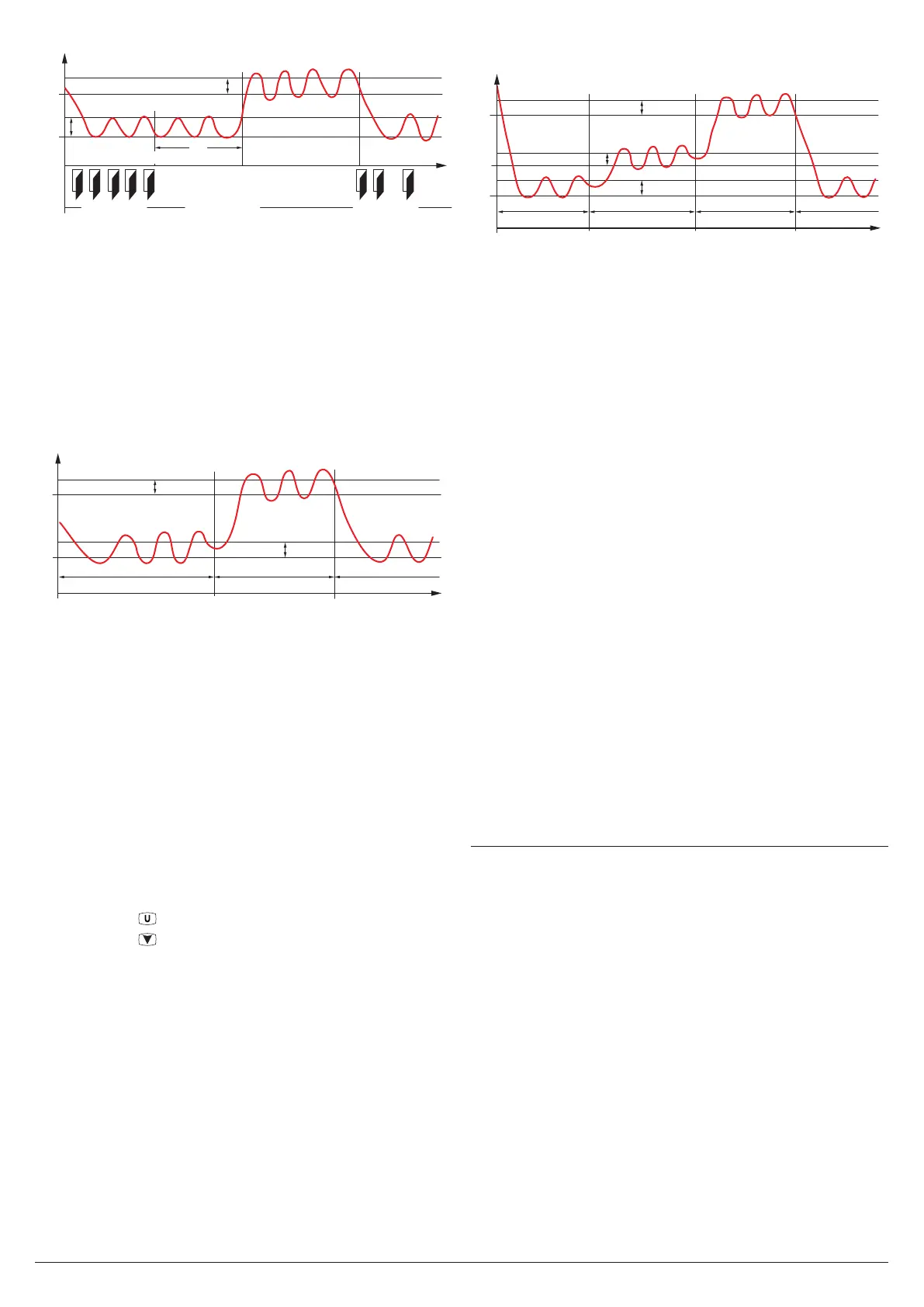

Temp.

SPE

SP

r.d

r.Ed

i.tt (2)

i.Et

time

Normal NormalECO

i.Et (1)

Pr1

Notes: 1. i.Et time is reset all the times the door is opened.

In the case shown, the door is always closed.

2. i.tt time stops when the door is opened and

the

instrument immediately switches to Normal mode.

In the case shown, the door is always closed.

When in Ecoal mode, the label Eco is displayed.

If i.dS = Ec the display sows the label Eco when the instru-

ment is in Ecoal mode. Otherwise the label Eco appears

approx. every 10 sEconds alternated with the normal display

set by the i.dS parameter.

The Eco mode selection is always combined with the turn

OFF the Auxiliary output function when used as a shop win-

dow light (o.Fo = 3).

Turbo/Normal/Eco mode operation

Turbo mode can be selected manually:

– Pressing the

key if parameter t.UF = 4;

– Pressing the

/AUX key if parameter t.Fb = 4;

– By a digital input if parameter i.oF = 8

(where o can be 1... 4).

Turbo mode can be selected automatically:

– Leaving Eco mode (only if r.HC = C3);

– Every time the instrument is turned on (only if r.HC = C3

and Pr1 > SPE + r.Ed)

.

The instrument quits Turbo mode automatically when r.tC

time has elapsed or manually using the programmed com-

mand (key or digital input); the instrument always returns to

Normal mode.

Turbo mode can be applied manually, for example when the

user wishes to lower the temperature of the products quickly

after loading the refrigerator. However, Turbo mode is ap-

plied automatically to restore product temperature at the end

of Eco mode.

Setting r.HC = C3 gives the following operating cycle:

Temp.

SPE

Eco

SP

SPH

Turbo

r.Hd

r.Ed

i.tt (2)

r.tCr.tC

time

Normal TurboECOTurbo

i.Et (1)

r.d

Pr1

r.Hc = C3

Notes: 1. i.Et time is reset all the times the door is opened.

In the case shown, the door is always closed.

2. i.tt time stops when the door is opened and

the

instrument immediately switches to Normal mode.

In the case shown, the door is always closed.

When switched ON, the instrument starts in the same mode

it was in when it was switched OFF (Normal or Eco) unless

the temperature at switch-on is higher than SPE + r.Ed. In

this case (see fig.) a Turbo cycle is automatically started.

After the r.tC time has elapsed, the instrument automatically

switches to Normal mode.

If the door is frequently opened the instrument remains in

Normal mode. If however the door is not opened for i.Et

time, it automatically switches to Eco mode. The instrument

remains in Eco mode until the door is opened again or, if set,

until the i.tt time-out has elapsed.

When leaving Eco mode, the instrument therefore runs a

Turbo cycle to allow the product temperature to be restored,

after which it reverts to Normal mode and so on.

When Turbo mode is ON, this is indicated by the characters

trb shown on the display alternated with the normal display.

The Normal SP Set Point can be set between the values

stored for S.LS and S.HS parameters, Eco Set Point SPE can

be set between the values of SP and S.HS and the Turbo Set

Point SPH can be set between the values of S.LS and SP.

Note: In the examples that follow, the Set Point is generically

indicated as SP and the histeresis as r.d, however,

operationally, the instrument will act on the basis of

the Set Point and of the histeresis selected as active.

5.3 Measure and display configuration

All parameters concerning measuring input are contained in

the ]In group.

With i.SE parameter it is possible to select the type of probe

connected to the instrument. Admitted types: thermistors

PTC KTY81-121 (Pt), NTC 103AT-2 (nt) or Pt1000 (P1).

With i.up parameter it is possible to select the temperature

measurement unit and resolution (C0 = °C/1°; C1 = °C/0.1°;

F0 = °F/1°; F1 = °F/0.1°).

The instrument allows the measuring to be calibrated, that

can be used for re-calibrating the instrument according to

application needs, through parameters i.C1 (for Pr1 input),

i.C2 (for Pr2), i.C3 (for Pr3) and i.C4 (for Pr4).

The usage of Pr2, Pr3 and Pr4 probes is defined by param-

eters i.P2, i.P3 and i.P4. These can be configured for the

following functions:

EP Evaporator Probe: used to manage the defrost and

the evaporator fans (see the relative paragraph);

Au Auxiliary Probe: can be used as a display-only probe

but it is also possible to assign it temperature alarms

(possible usages: product, antifreeze probe, etc.);

Loading...

Loading...