Servicemanual TD60

19

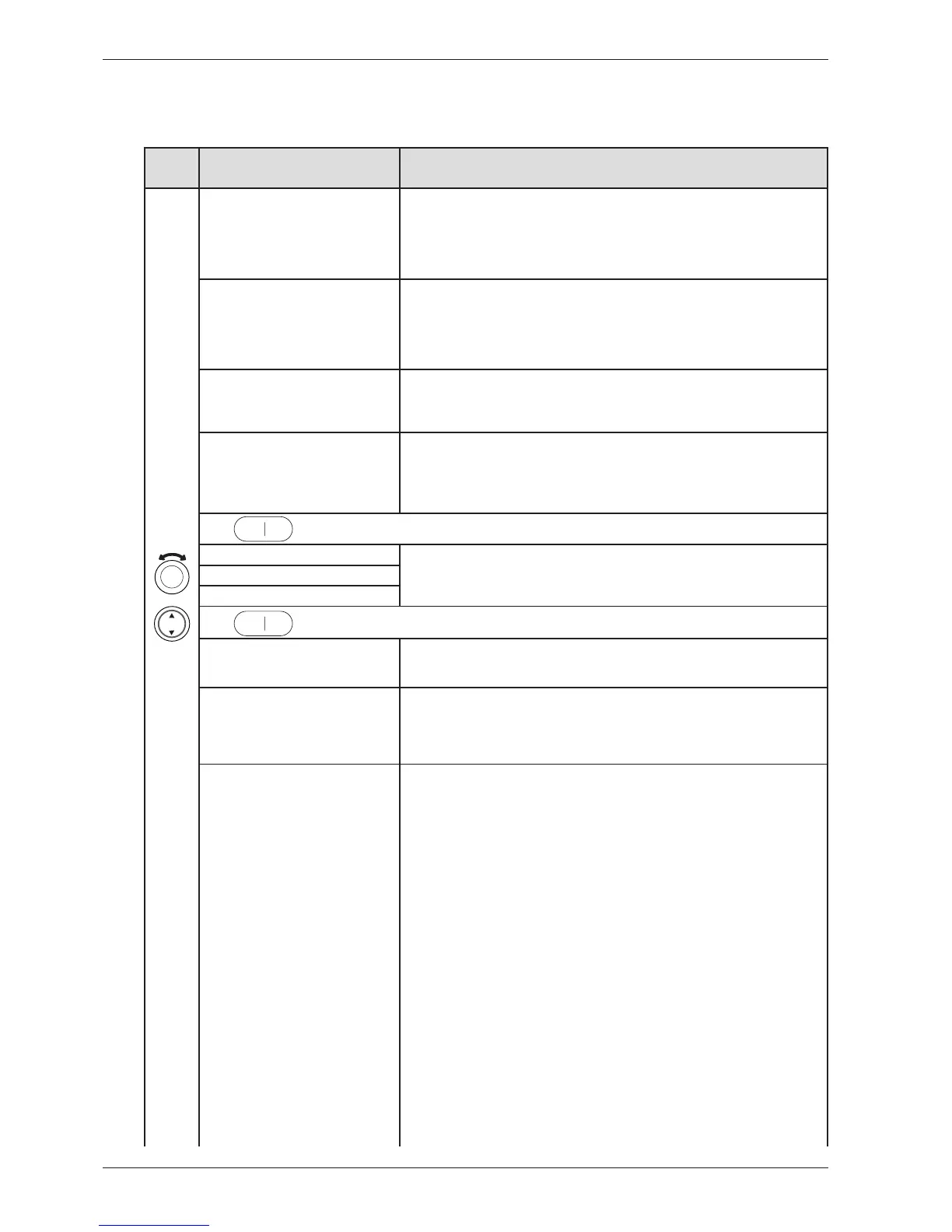

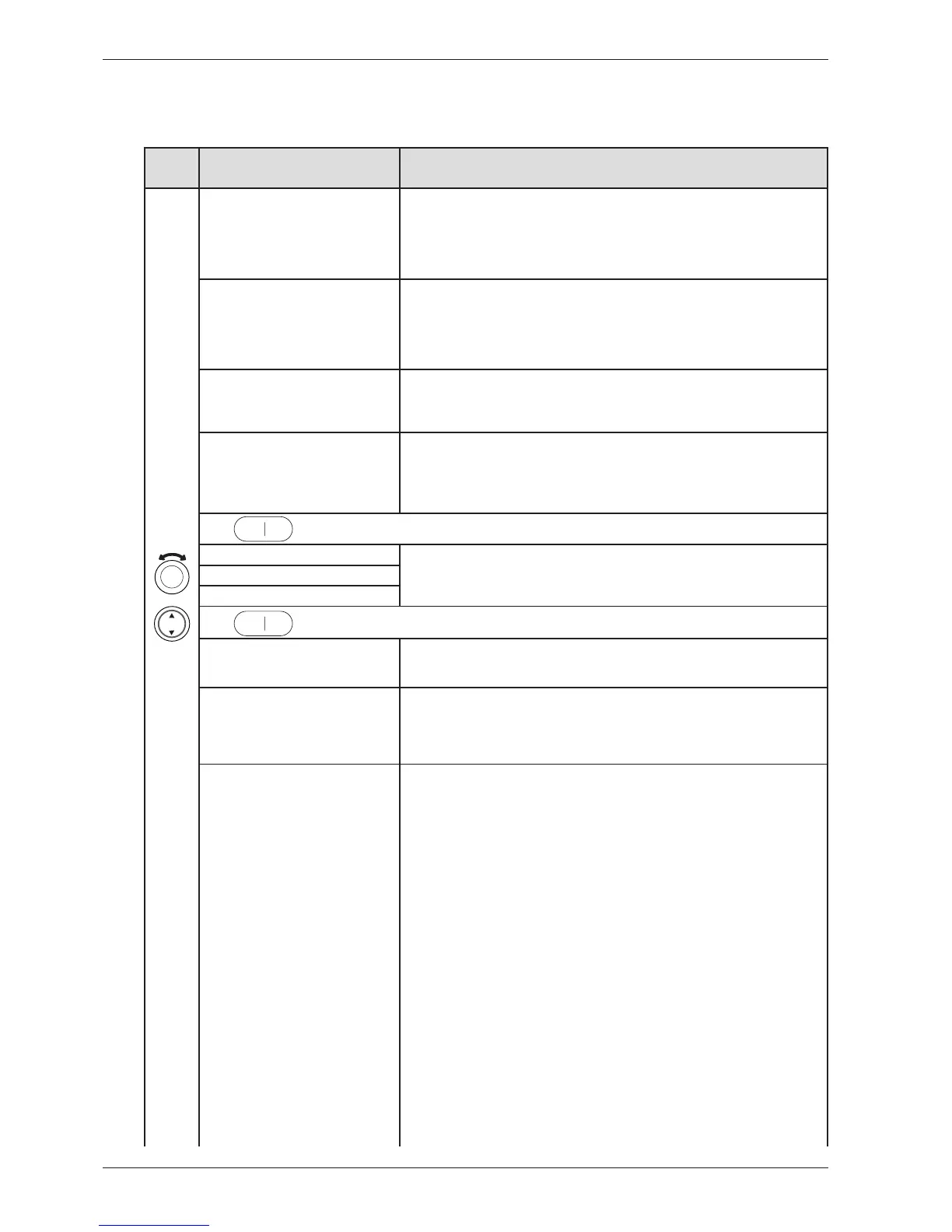

Press/

turn

LCD 2 Comments/instructions

DataSerialNo, Data Ser Num, Data-

SerialNo, DataSerialNo, Serienummer,

Serienummer, Dataversio Nro, N° de

série, Seriennummer, Num. di serie, N°

de serie, Сeрийный нoмeр , Serienum-

mer

Date for programming the software (Year_Week)

CU date code, CU Date Code, CU

date code, CU datum kod, CU dato

kode, Styrekort prod dato, CU pvm

koodi, Code date CU, CU Datums-

code, Codice data CU, Código fecha

CU, Кoд дaты БУ, CU datacode

Control unit’s date of manufacture (Year_Week)

Software, Software, Software, Mjukva-

ra, Software, Software ver., Ohjelmisto,

Logiciel, Software, Software, Software,

Beрсия пpoг., Software

Software version number.

No. of cycles, Number of Cycles, No.

of cycles, Antal cykler , Antal cyklusser,

Antall bruk, Syklien lkm, Nb. de cycles,

Anzahl der Zyklen, Numero cicli, N° de

ciclos, Кoл-вo циклoв, Aantal cycli

Number of cycles/programs run

Press

to exit the service menu.

Testing, Test, Test, Tester, Test, Testaus,

Essai, Test, Test, Test, Teстиpoвaниe,

Testen

Testing Motor, Test motor, Motortest,

Tester motor, Test av motor, Moot-

toritesti, Essai moteur, Test motor, Test

motore, Test motor, Teст мoтopa,

Motor testen

Normal action: The motor will run continuously.

Testing Heater 1, Test heater 1, Ele-

menttest 1, Tester varmelegeme 1, Test

av element 1, Vastustesti 1, Essai él.

chauf 1, Test verw. element 1, Test el.

risc. 1, Test elem calef 1, Teст TЭHa 1,

Heizungstest 1

Motor runs continuously. Heater 1 runs regulated on and off by CU regarding to

measured thermistor values. Total consumption is app. 9A in this mode. If value differs,

do the following:

1. Detach the panel

2. Disconnect electrical connections at the CU.

3. Measure DC Ω for heaters and related wires. For values and measure points, see

chapter ”Components and measurement values” and ”Wiring diagram”.

IF THE VALUES ARE INCORRECT:

Check the electrical function for connections and heater. Change parts if needed.

IF THE VALUES ARE CORRECT:

a) Start the component test (”Test heater 1”)

b) Measure AC voltage directly on the CU (see wiring diagram for measuring points).

Voltage should be the same as power supply net.

c) If values are out of range: Replace the CU.

LCD shows ”_ _ _ _ _ _ _ _ : XX°C YY°C ZZ °C”.

XX = temperature values for thermistor 1

YY = temperature values for thermistor 2

ZZ = temperature values for thermistor 3

>100°C (XX) = short-circuit in thermistor 1 (heating element does not start)

10°C (XX) = thermistor 1 faulty (heating element heats but is only regulated by the

overheating protection).

>100°C (YY) = short-circuit in thermistor 2 (heating element does not start)

10°C? ± 2°C (YY) = thermistor 2 faulty (functions as vented dryer).

150°C (ZZ) = thermistor 3 short-circuited

25°C (ZZ) = thermistor 3 faulty

CONTINUE ON NEXT PAGE

The options below are displayed in the order they occur in LCD 2. All display text language ver-

sions are displayed.

Service menu TD60.3

Loading...

Loading...