Servicemanual TD60

26

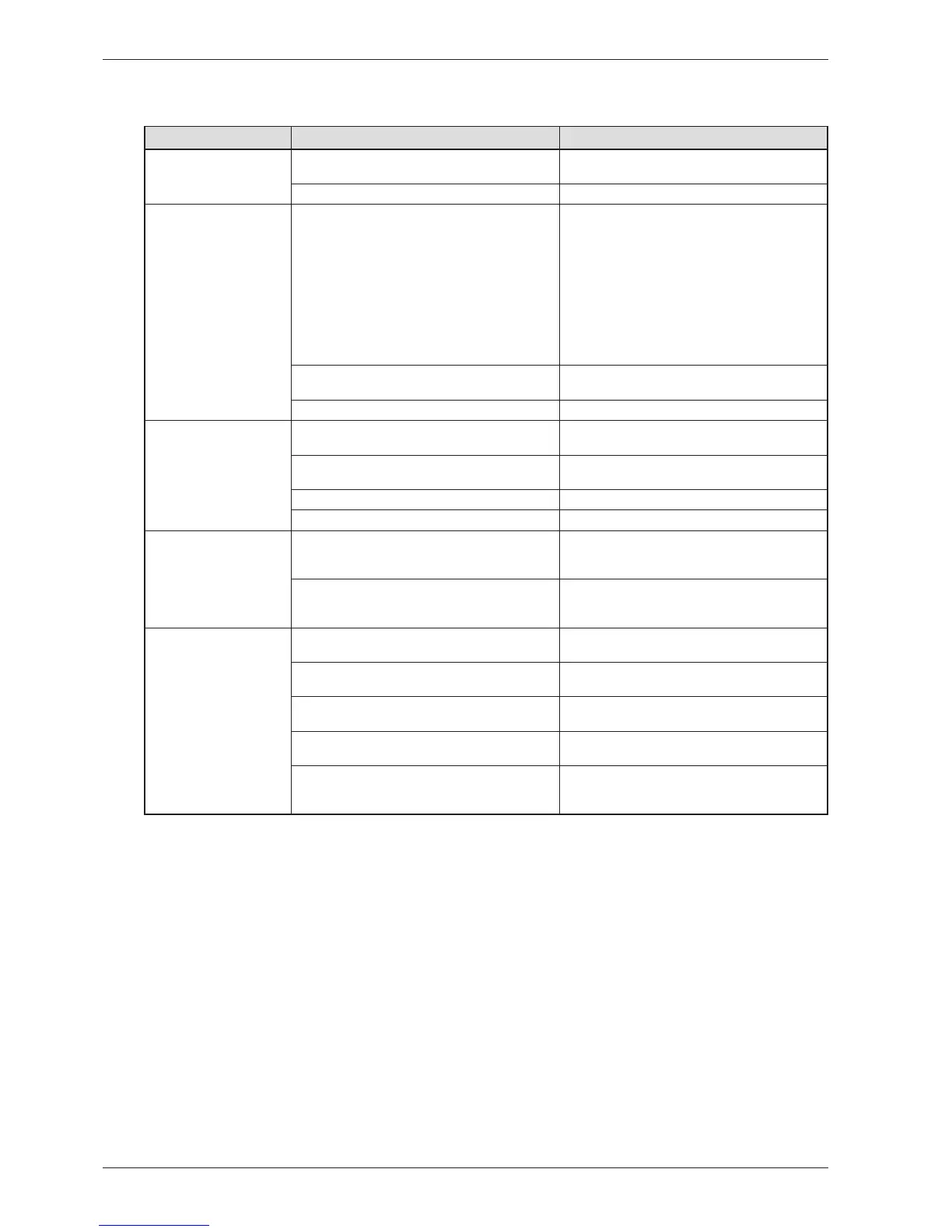

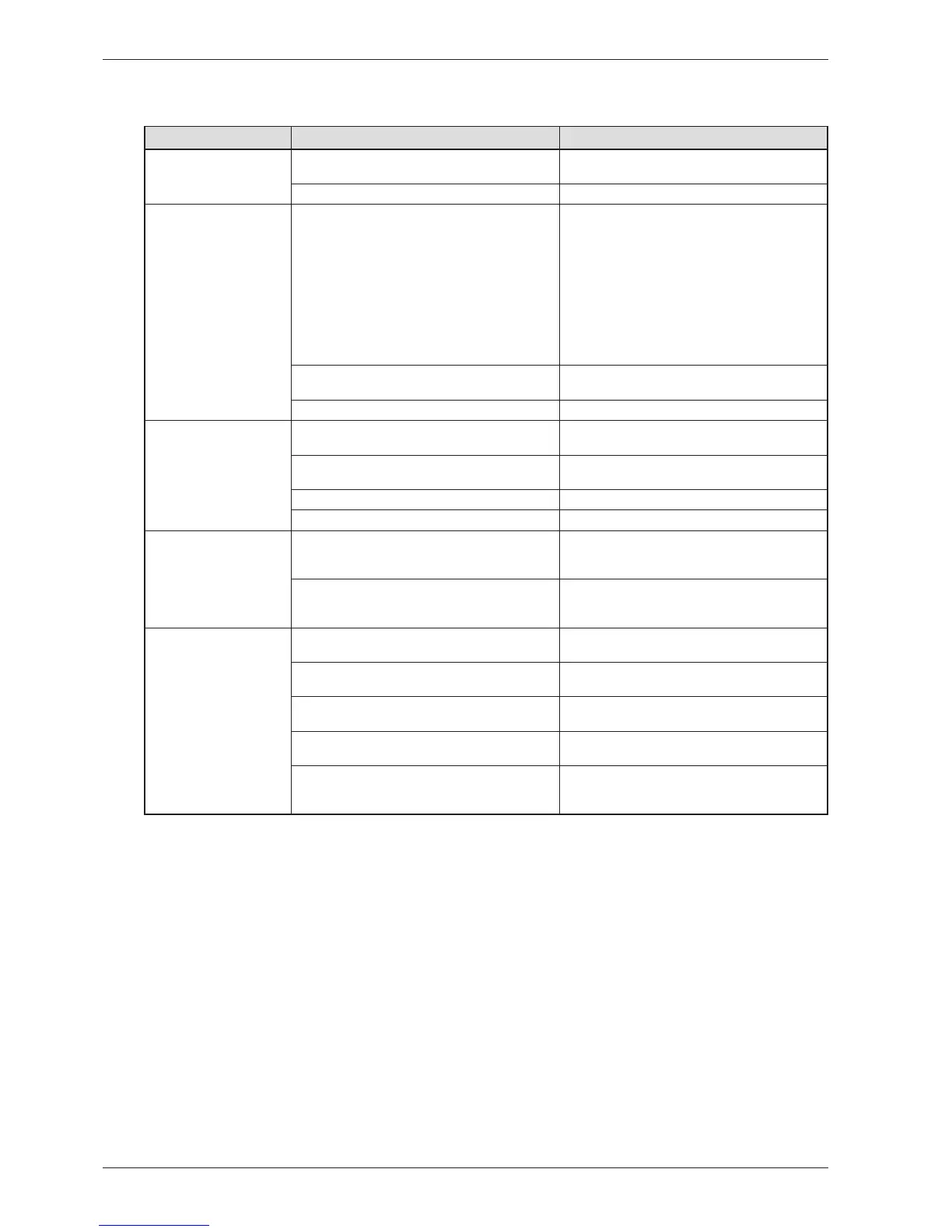

Other faults TD60

Fault symptom Cause Action

The machine will

not start

The outer door is not properly closed. • Check that the door pin is activating the door

switch.

The machine is not supplied with power. • Check the fuses and connections.

The machine stops

The automatic overheating protection has tripped. Check if the customer has:

• Opened the door and cleaned the filter and con-

denser unit

• Left the door open long enough for the overheating

protection to be reset

and the display and LEDs to light up

• Attempted to restart the program

Service action:

• Clean internal fan wheel, condenser, air ducts and

element.

• Check the seals.

The overheat protection in the motor has been

tripped.

• Clean and check the motor.

• If necessary, replace the motor.

Defective control unit • Replace control unit.

The washing does

not get dry

Air leakage at the door seals is affecting the drying

results.

• Check the sealing strips.

Air leakage around the motor shaft affects the drying

result.

• Check the seal around the motor shaft.

Defective rear thermistor • Replace the thermistor.

Defective control unit • Replace control unit.

The washing does

not get dry.

Mixing of various types of items can lead to uneven

drying results.

Customer information:

• Check that different types of items are not mixed

in the same machine. Remove the dry items.

How full the machine is affects the drying results. Customer information:

• Check that the machine is not overfilled. Remove

some of the washing if necessary.

Tumble-drying

takes too long.

The lint filter is blocked. Customer information:

• Cleaning the lint filter.

The condenser unit is blocked. Customer information:

• Clean the condenser.

The washing machine’s spinning affects drying. Customer information:

• Spin at a minimum of 800 rpm.

The machine is in a room with poor ventilation. Customer information:

• Open doors to adjacent rooms.

The evacuation hose is too long, blocked or bent. Customer information:

• Try to make the hose length as short as possible

with as gentle bends as possible.

Loading...

Loading...