Faults and Failure

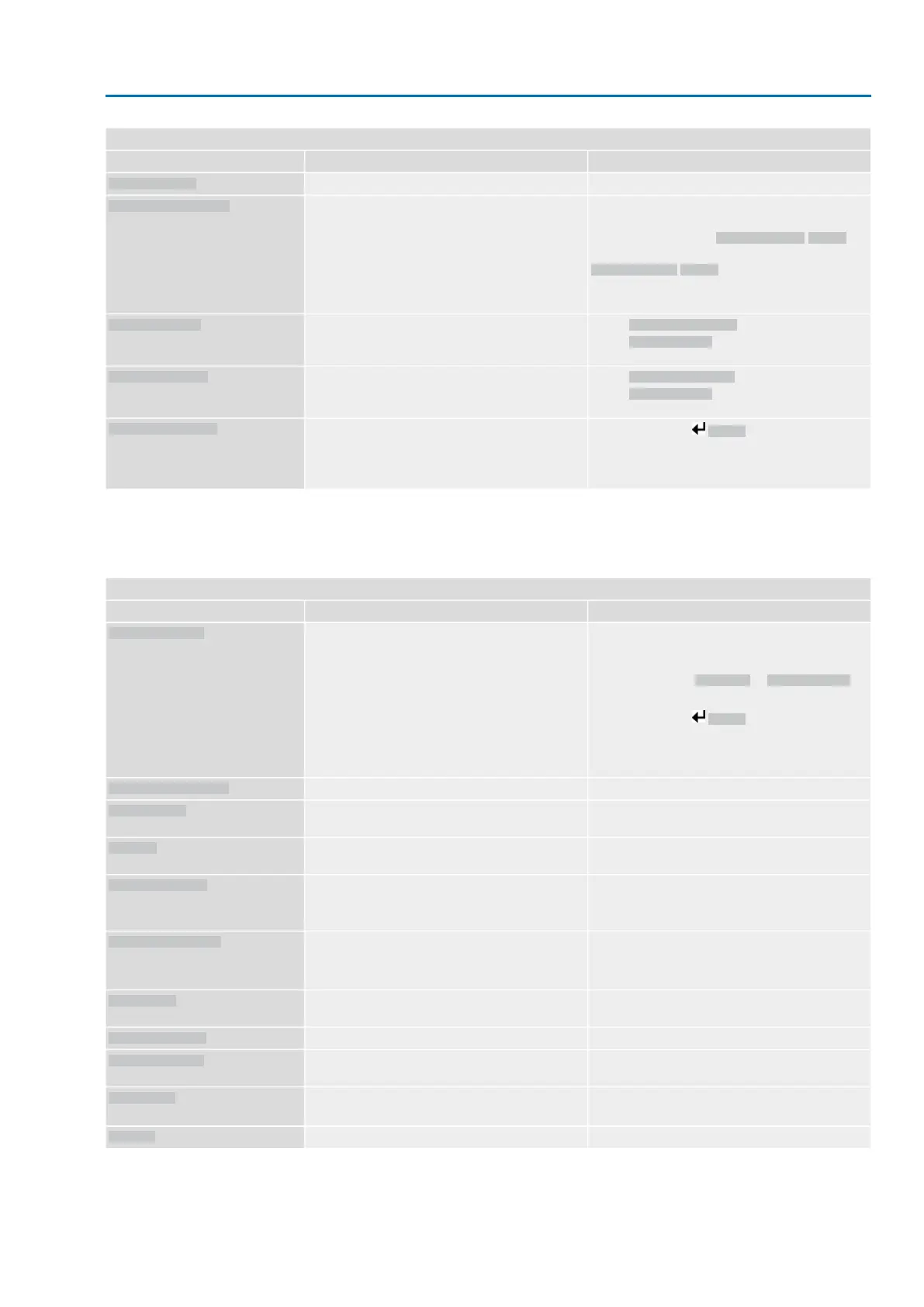

RemedyDescription/causeIndication on display

Check wiring.Loss of signal analogue input 2

Wrn input AIN 2

Check operation command control.

For 3-phase AC current mains, activate phase

monitoring (parameter Adapt rotary dir. M0171).

Check device configuration setting (parameter

Closing rotation M0176).

To delete the fault indication: Disconnect actuator

controls from the mains and perform reboot.

Contrary to the configured direction of rotation and

the active operation command, the motor turns into

the wrong direction.

Incorrect rotary direct.

Check DMF trip torque OP parameter.

Check DMF fault level parameter.

The torque in direction OPEN, measured at the

output drive shaft using the torque measurement

flange, is too high.

DMF fault OPEN

2)

Check DMF trip torque CL parameter.

Check DMF fault level parameter.

The torque in direction CLOSE, measured at the

output drive shaft using the torque measurement

flange, is too high.

DMF fault CLOSE

2)

Press push button Details to display a list of indi-

vidual indications.

For a description of the individual signals, refer to

Manual (Operation and setting).

Collective signal 25:

FQM collective fault

3)

For lift plug valve product variant1)

For actuators equipped with torque measurement flange (DMF)2)

For actuators equipped with fail safe unit3)

Table 40:

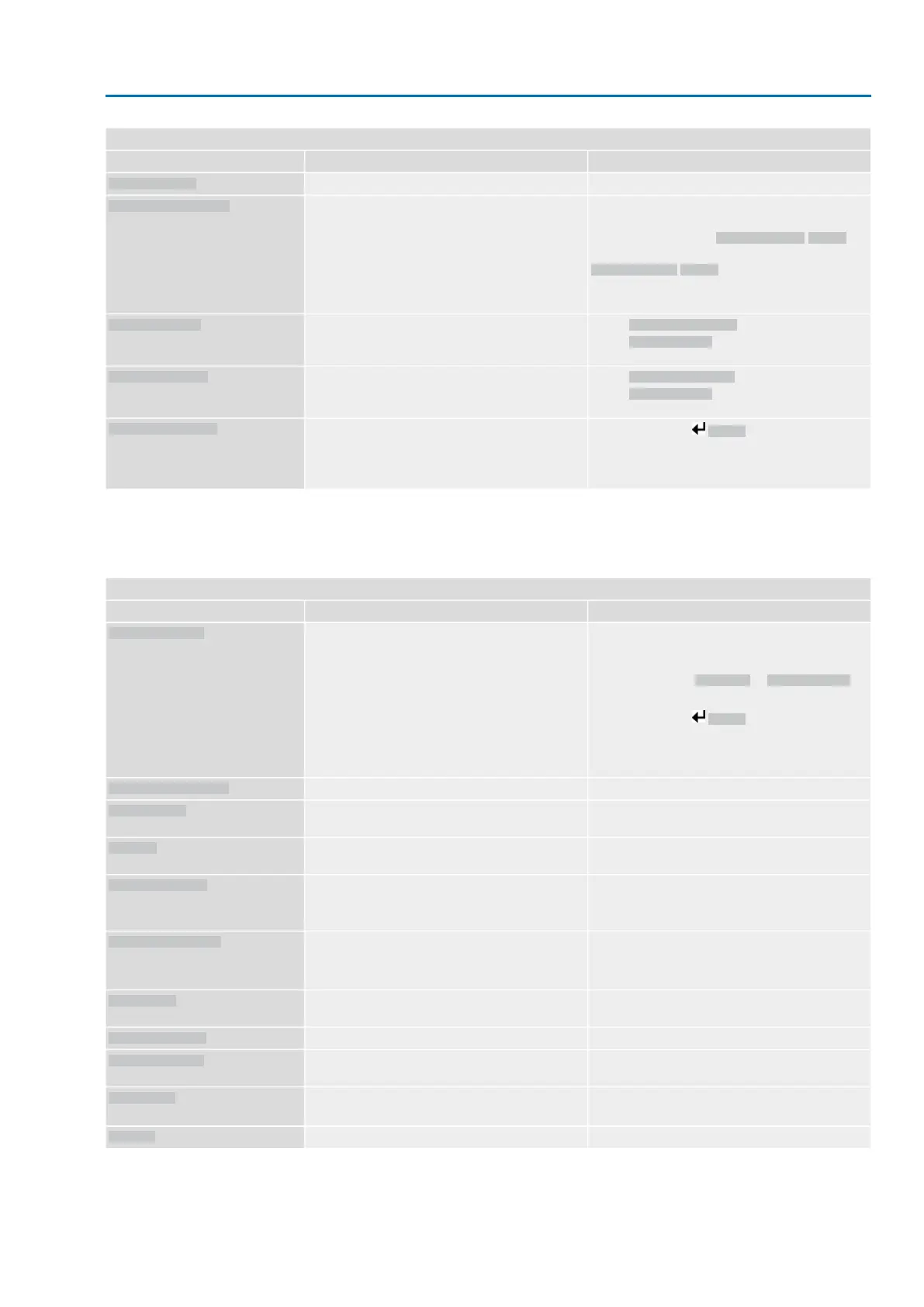

Not ready REMOTE and Function check (collective signal 04)

RemedyDescription/causeIndication on display

●

Check operation commands (reset/clear all op-

eration commands and send one operation

command only).

●

Set parameter Positioner to Function active.

●

Check setpoint.

Press push button Details to display a list of indi-

vidual indications.

For a description of the individual signals, refer to

Manual (Operation and setting).

Collective signal 13:

Possible causes:

●

Several operation commands (e.g. OPEN and

CLOSE simultaneously, or OPEN and SET-

POINT operation simultaneously)

●

A setpoint is present and the positioner is not

active

Wrong oper. cmd

Set selector switch to position REMOTE.Selector switch is not in position REMOTE.

Sel. sw. not REMOTE

Exit service software.Operation via service interface (Bluetooth) and

AUMA CDT service software.

Service active

Check setting and status of function <Local controls

enable>.

Actuator is in operation mode Disabled.

Disabled

●

Enable EMERGENCY stop switch.

●

Reset EMERGENCY stop state by means of

Reset command.

The EMERGENCY stop switch has been operated.

The motor control power supply (contactors or

thyristors) is disconnected.

EMCY stop active

●

Detect cause for EMERGENCY signal.

●

Verify failure source.

●

Apply +24 V DC at EMERGENCY input.

Operation mode EMERGENCY is active (EMER-

GENCY signal was sent).

0 V are applied at the EMERGENCY input.

EMCY behav. active

Check I/O interface.The actuator is controlled via the I/O interface (par-

allel).

I/O interface

Start motor operation.Manual operation is activated.

Handwheel active

Verify master configurationFieldbus connection available, however no process

data transmission by the master.

FailState fieldbus

Release push button STOP.A local STOP is active.

Push button STOP of local controls is operated.

Local STOP

Check interlock signal.An interlock is active.

Interlock

85

SAEx 07.2 – SAEx 16.2/SAREx 07.2 – SAREx 16.2 Control unit - electromechanical

ACExC 01.2 Intrusive Modbus RTU Corrective action

Loading...

Loading...