5.5 Further Bottom Blowdown Time Reduction Savings Calculations

Bottom blowdown time reduction is used to control the opening time in ratio to the steam production. In

this way, the losses incurred from bottom blowdown can be lowered.

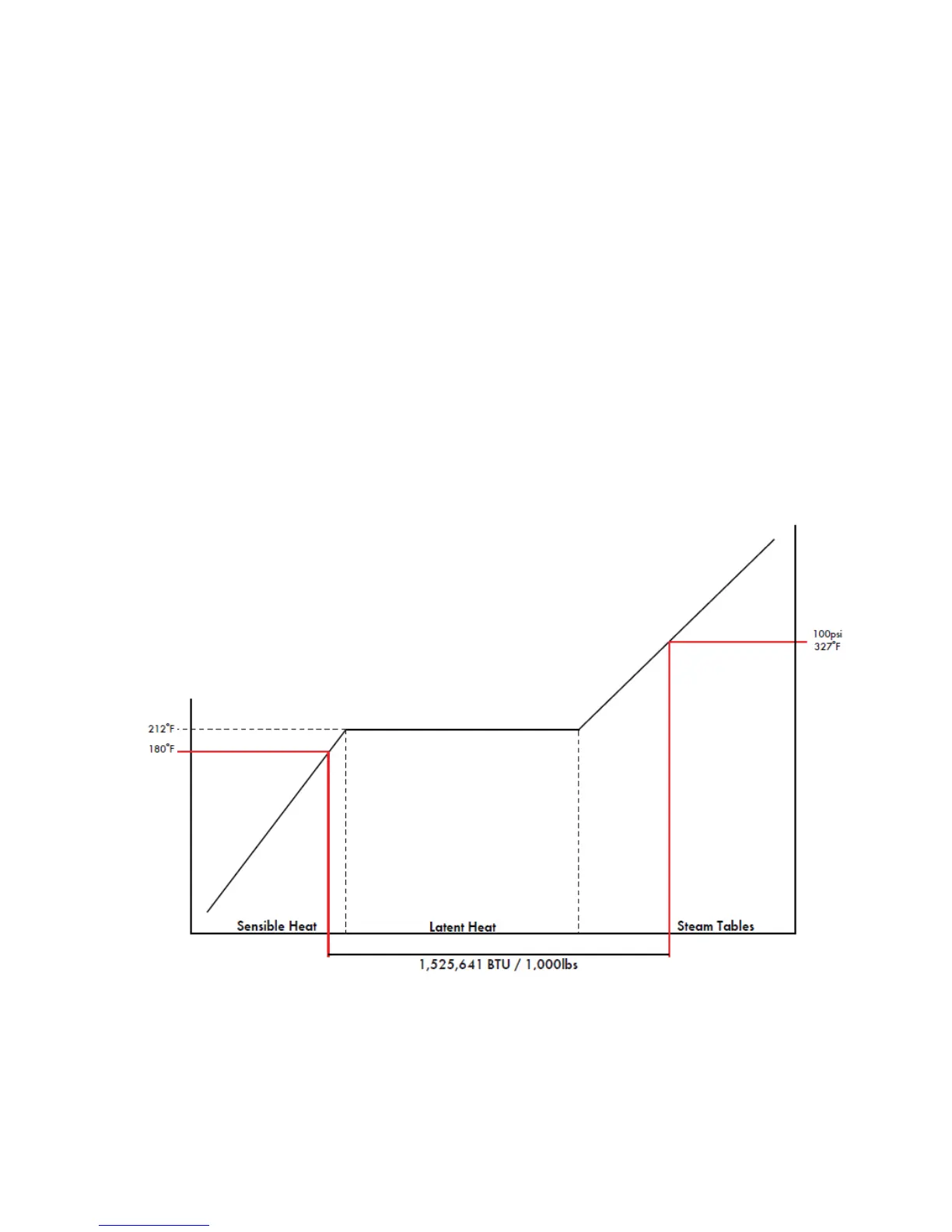

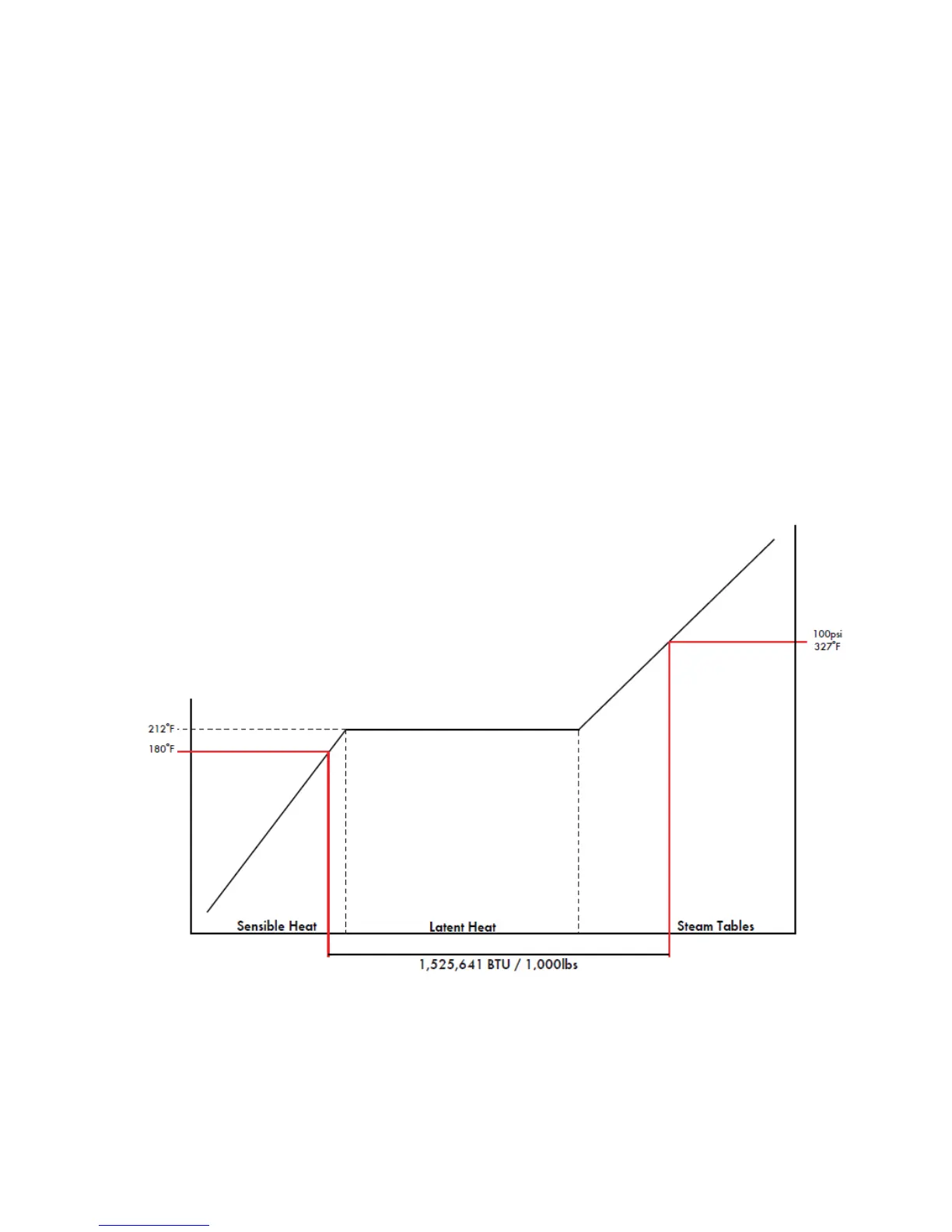

The example below is based on the heat required to generate steam from feed water at 180degF to

steam at 100 PSI (327degF). It is recognised in the steam industry that a typical steam boiler will lose

3% of its energy in steam generation to bottom blowdown management.

If a 20,000lb/hr boiler firing on natural gas is operating at Maximum Continuous Rating (M.C.R.), the

total required heat input would be 25,000,000 BTU/hr including 20% stack losses and 2% standing

losses.

Therefore for a typical shift cycle of 8 hours at 20,000lb/hr, which is approximately 200,000,000

BTU in heat. The typical blowdown losses of 3% would then be 6,000,000 BTU.

Assuming that £10.25 ($15.62) gives 1,000,000 BTU for firing on natural gas, the cost of

conventional bottom blowdown management at M.C.R. over 8 hours would be £61.50 ($93.62).

Assuming that £14.96 ($22.80) gives 1,000,000 BTU for firing on no.2 oil, the cost of conventional

bottom blowdown management at M.C.R. over 8 hours would be £85.27 ($129.94).

Loading...

Loading...