3.1.2 Steam Flow Induced Surge

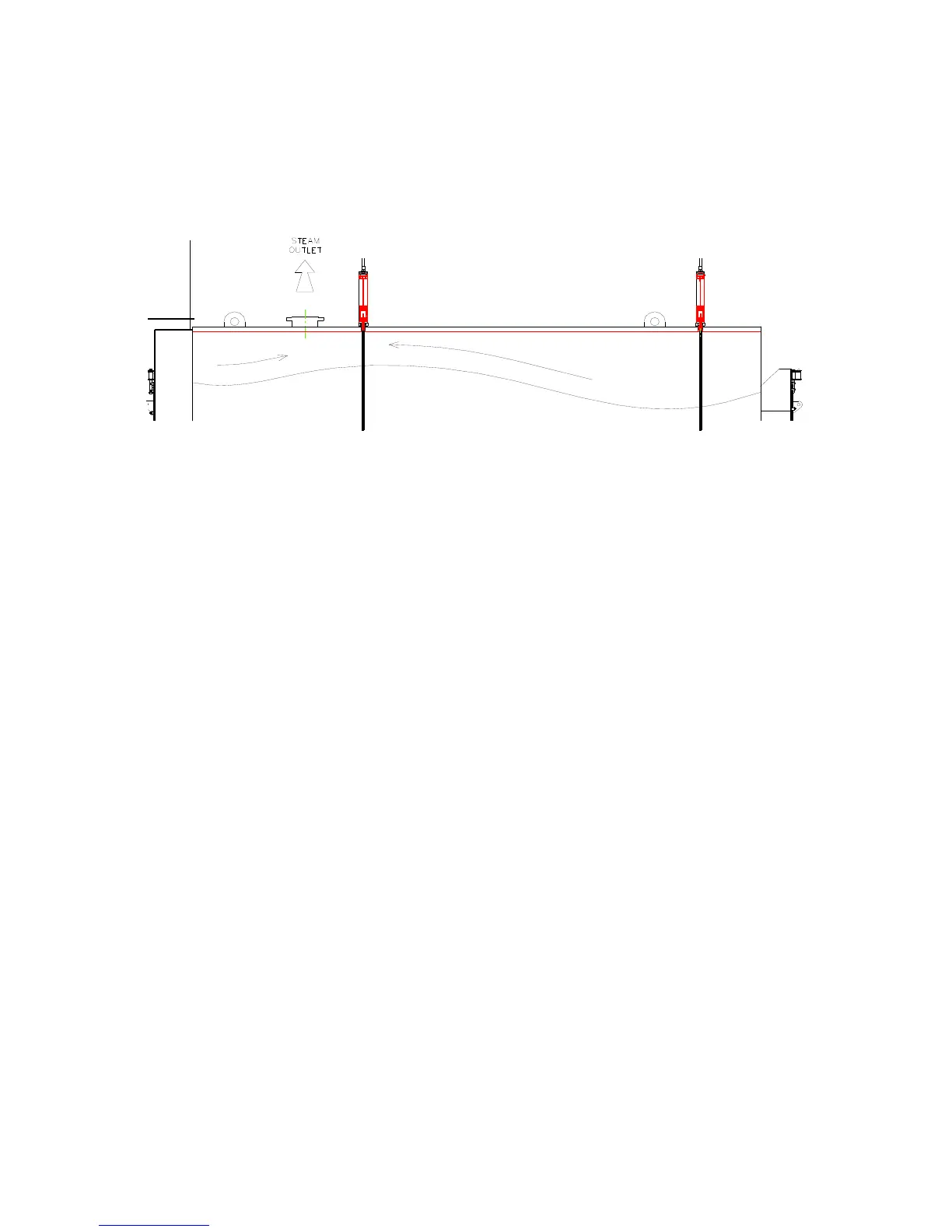

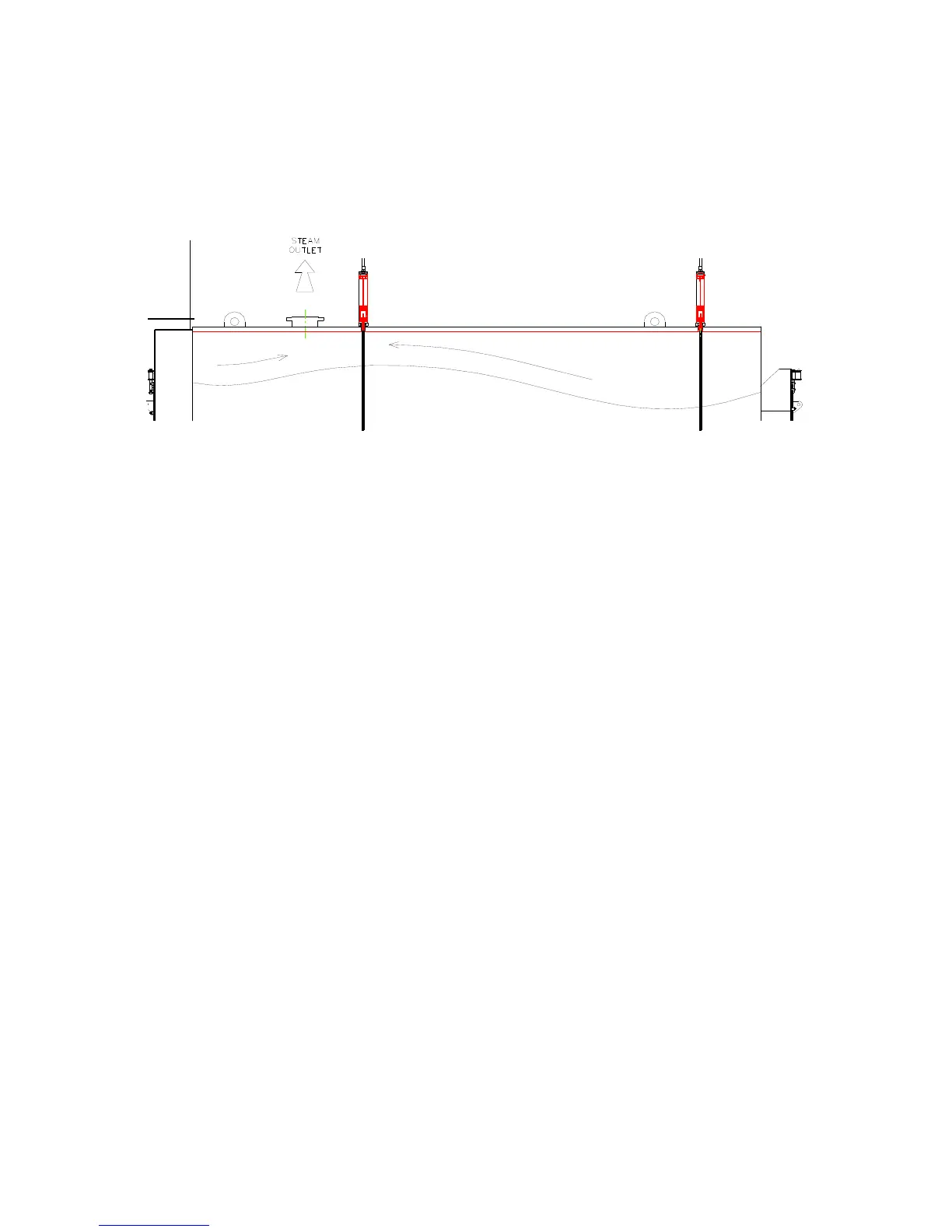

When the boiler is producing high quantities of steam, this steam travels over the surface and can

produce swells and surging motions (long wave).

The above situation will be shown in high relief when the steam outlet is at one end of the boiler and

one level probe is sited adjacent to the steam outlet and the second probe is sited at the opposite end

of the boiler. The user adjustable probe disparity value may have to be increased to take this situation

into account.

3.1.3 Foaming

Foaming on the surface of the boiler is brought about by a less than adequate blow down regime

and/or not controlling and managing TDS in the appropriate manner. Incorrect or insufficient water

treatment will exacerbate all of the above. Foaming will read as a step increase in water level. This

situation should only ever occur in a badly managed boiler plant.

It can be seen from the above examples that wave signature will tend to be very installation specific. It

is driven by boiler size, water treatment regime, position of heat transfer surface relative to water level

and the load pattern imposed on boiler.

The Autoflame system takes into account all of these variables and uses them to create a control

algorithm that produces perfect level control with absolute safety.

Loading...

Loading...