6 STEAM AND HEAT FLOW METERING

6.1 Steam Flow Metering

Autoflame steam flow metering is available in the water level control; it has been granted an

international patent. By the addition of one temperature detector it is possible to extrapolate steam

flow from a boiler both as an instantaneous value and a totalised amount over time. A full steam flow

metering package is available with just the addition of one temperature sensor to the expansion board,

avoiding the cost of an expensive steam flow meter and orifice plate that is typically accurate at the

higher firing rates only.

An explanation of this is detailed below in the example:

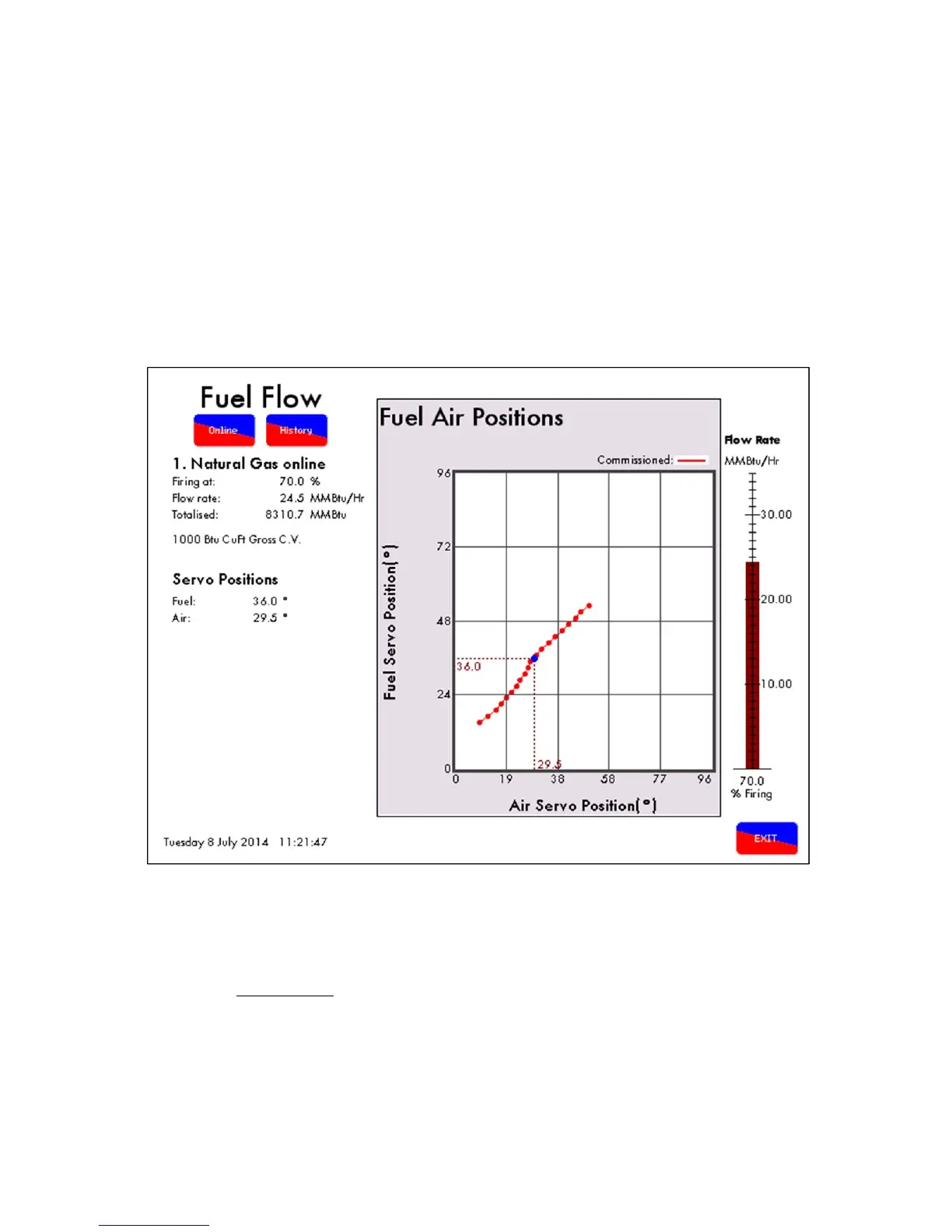

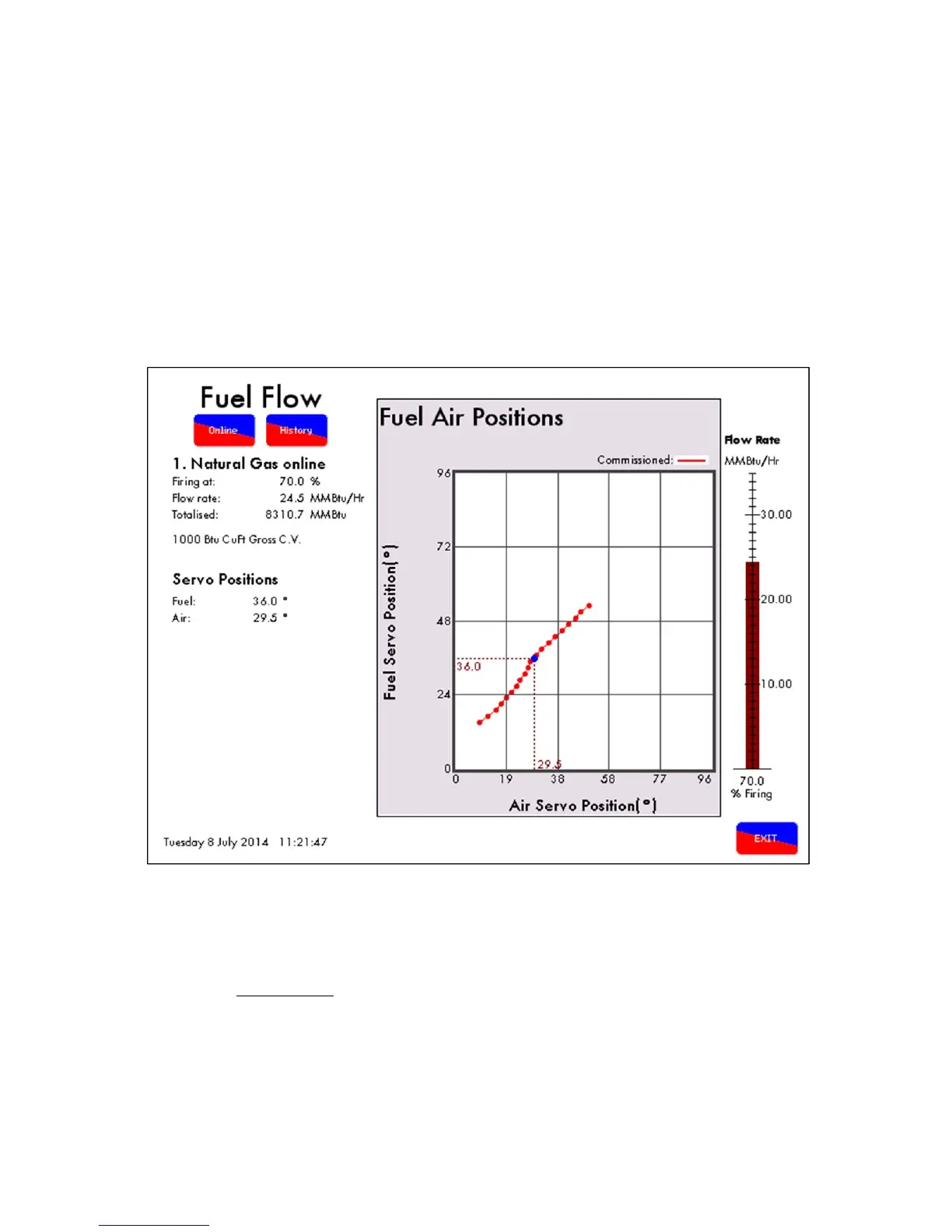

Figure 6.1.i Fuel Air Positions

From Fuel Flow Metering it can be seen that the fuel gross calorific heat input is 24.5 million BTU/hr.

Therefore 24,500,000 BTU/hr (gross fuel calorific value)

Less 245,000 BTU/hr (1% loss standing losses, expansion option 9.1)

Less 4,410,000 BTU/hr (18% stack loss)

Equals 19,845,000 BTU/hr (net calorific value of the fuel into the wet side of the boiler)

Note: If an E.G.A. is used, the stack loss is taken from the E.G.A. greater accuracy.

Loading...

Loading...