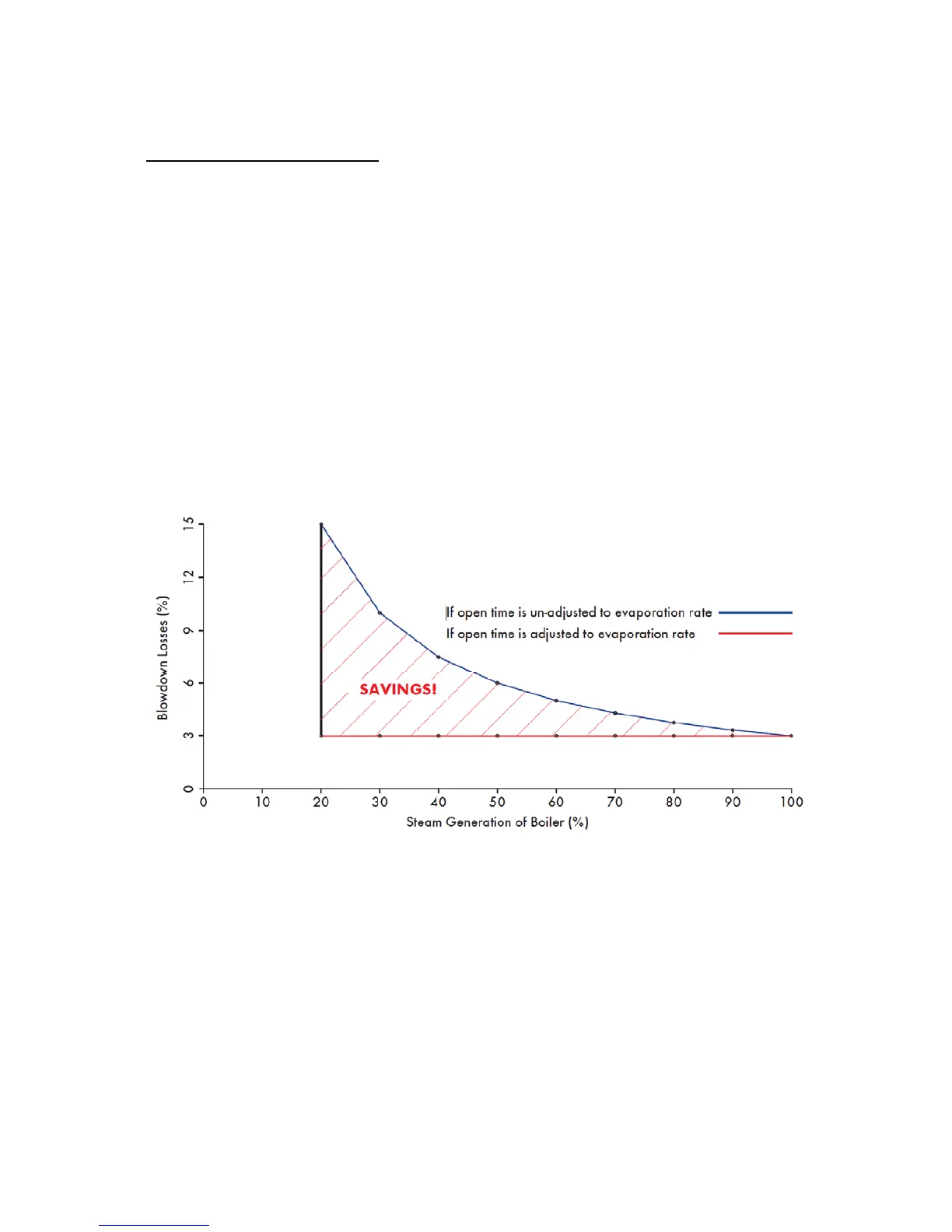

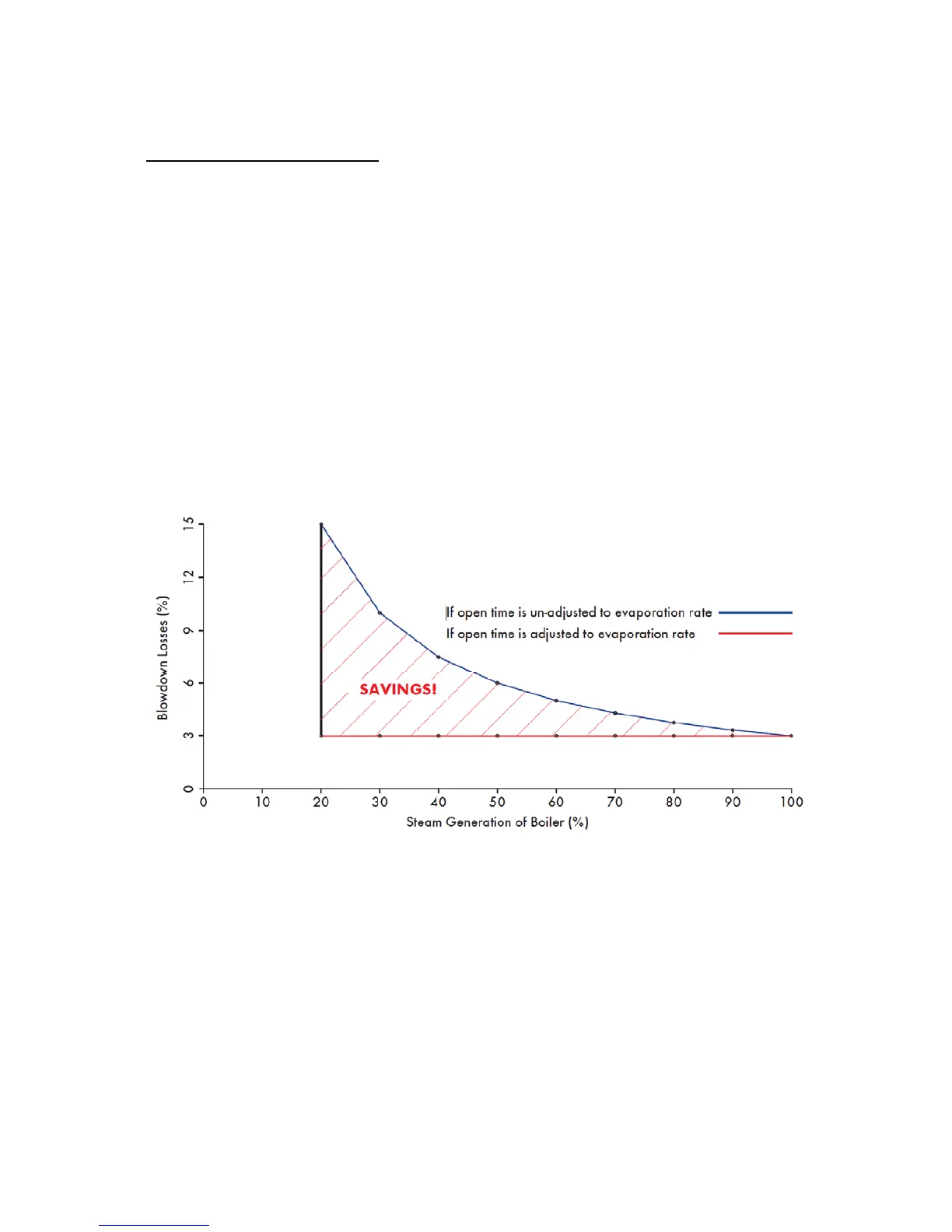

5.1.2 Bottom Blowdown Time Reduction

Calculated Bottom Blowdown Losses

With a typical loss in steam generation of 3% from the conventional bottom blowdown management,

Autoflame have developed a Bottom Blowdown Time Reduction feature to minimise these losses which

occur when keeping the boiler heat transfer surfaces clean.

It follows that blowdown time can be reduced as a function of the rate of steam generation. Silt and

sludge formation within the boiler is always in ratio to work done or steam generation. Therefore the

reduction in the blowdown valve open time can be made, as long as the reduced open time is in ratio

to the evaporation rate or steam generation rate.

Blowdown savings in the region of 1-2% are possible on total fuel usage

(dependant on boiler load)

Blowdown timing automatically reduced in ratio to steam generation

Blowdown timings set by users

Operators may only trigger pre-set timings, eliminates excessive blowdown by operator

Ensures minimal blowdown to satisfy removal of solids, silt and sludge

For time reduced bottom blowdown, steam flow metering is required, this can be set through expansion

option 38.1 (see section 2.2). The accurate burner rating must be set through M.M. options 33 and

77, as well accurate fuel flow metering through M.M. option 57.

Loading...

Loading...