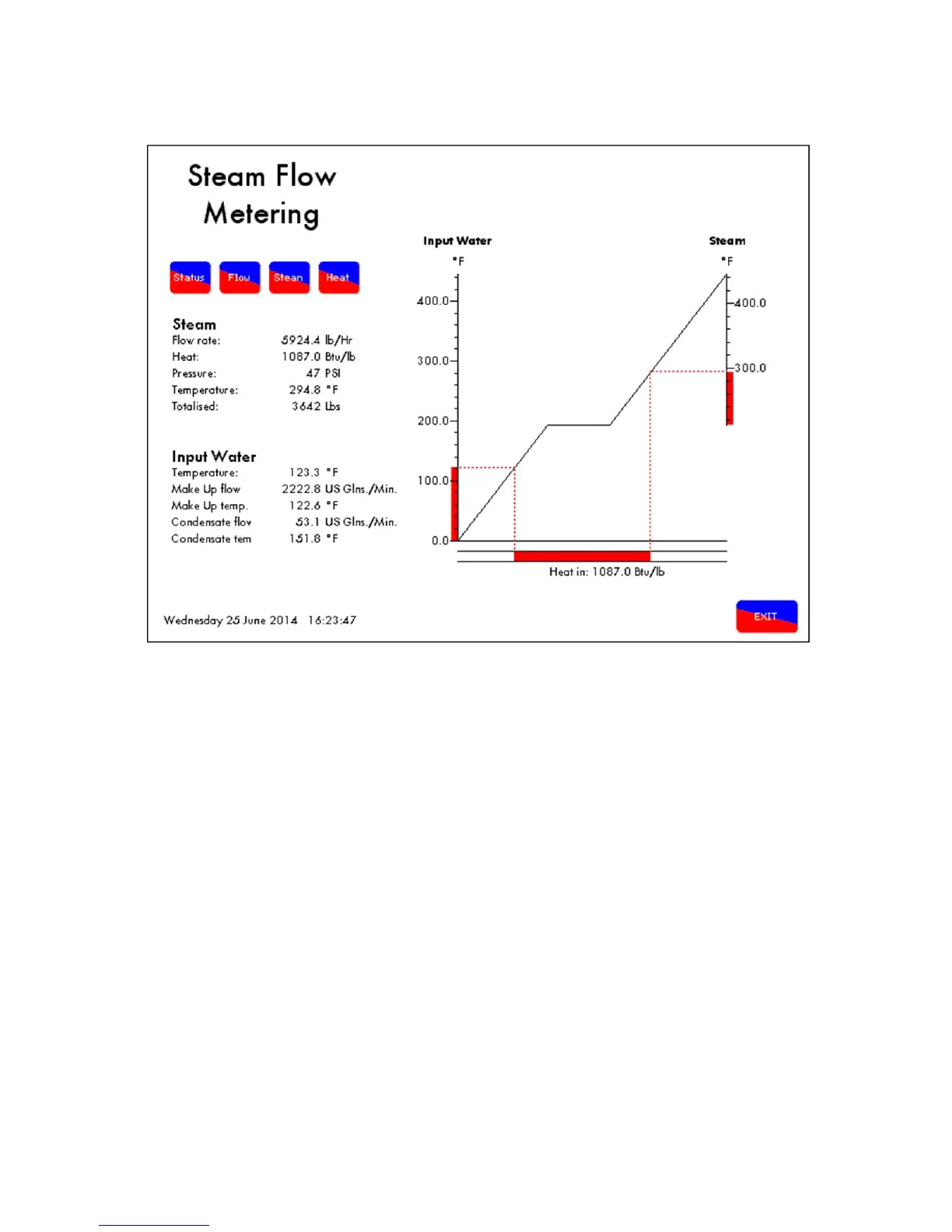

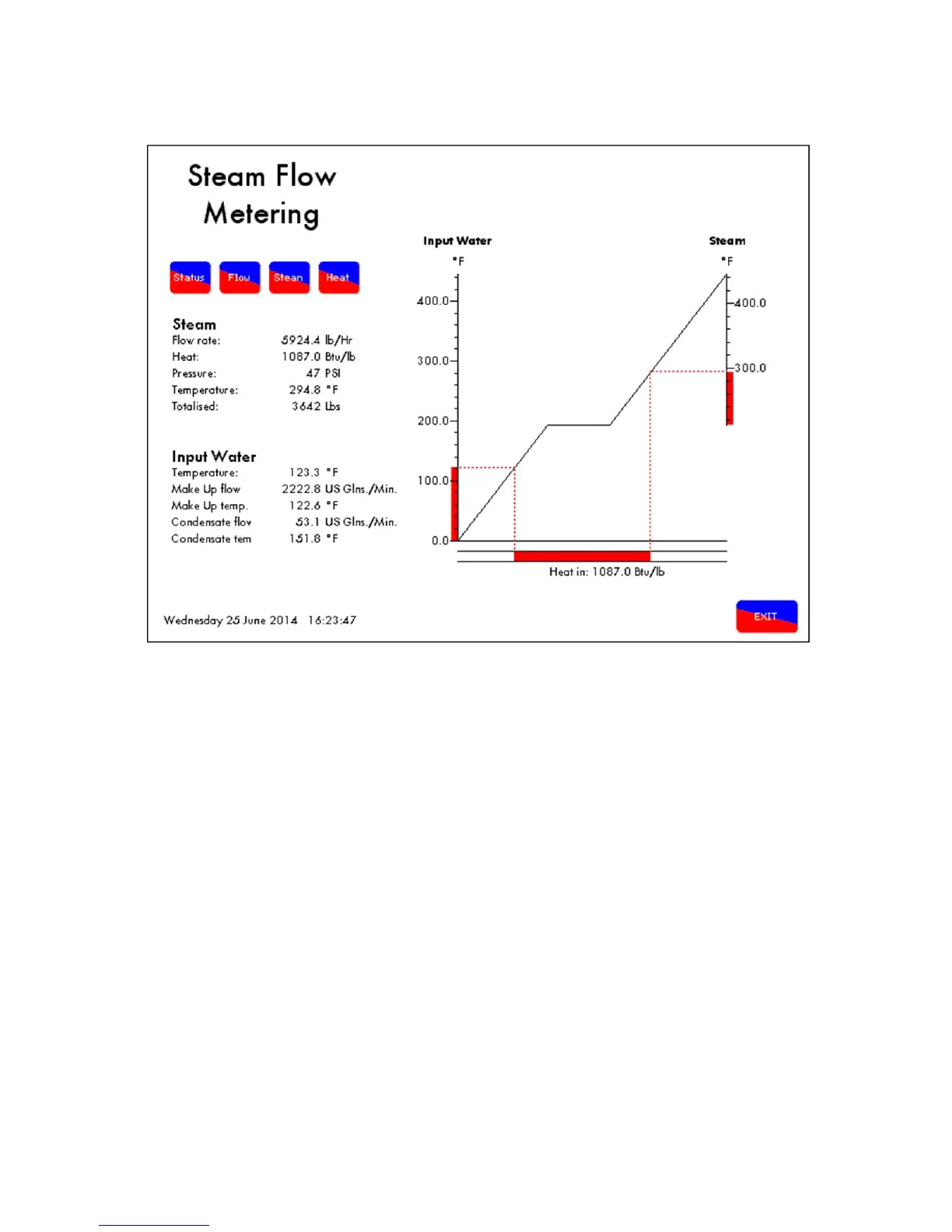

6.1.1 Steam Flow Metering Incorporating a Deaerator

Figure 6.1.1.i Steam Flow Metering with Deaerator

A common practice in steam generation is the use of a “deaerator” to remove the oxygen from the

feed water and hence reduce the incidence of oxygen corrosion in the boiler, steam and condensate

pipe work.

The principle of a deaerator is to mix the make-up water with the condensate return and live steam

direct from the boiler in a tank. Flash steam may also be directed back to the tank. The effect is to

mechanically “scrub” the oxygen from the feed water and also to preheat it before it is pumped to the

boiler.

In the system as set out above it is no longer valid to measure the temperature of the feed water just

before it enters the boiler as the inlet temperature for the “steam meter” calculation. This water has

already been preheated by steam from the boiler and therefore this additional energy should not be

taken into the software calculation.

The solution is to treat the boiler and deaerator as one system. The energy into the system is supplied

by the burner and the inlet temperature is the “weighted average” of the condensate return

temperature and makeup water temperature. The outlet steam temperature is measured by a

temperature sensor in exactly the same way as in a system without a deaerator.

Loading...

Loading...