*IMPORTANT NOTE: THE NOTES AND MECHANICAL EXECUTIONS IMPLICIT IN THESE DRAWINGS ARE FOR GUIDANCE

PURPOSES ONLY. LOCAL, NATIONAL AND STATE CODES MUST BE ADHERED TO IN ALL CASES. IT IS IMPORTANT TO

USE ONLY QUALIFIED AND EXPERIENCED INSTALLATION PERSONNEL. AUTOFLAME TECH CENTRES CAN ADVISE.

IF IN DOUBT, PLEASE CONTACT AUTOFLAME.

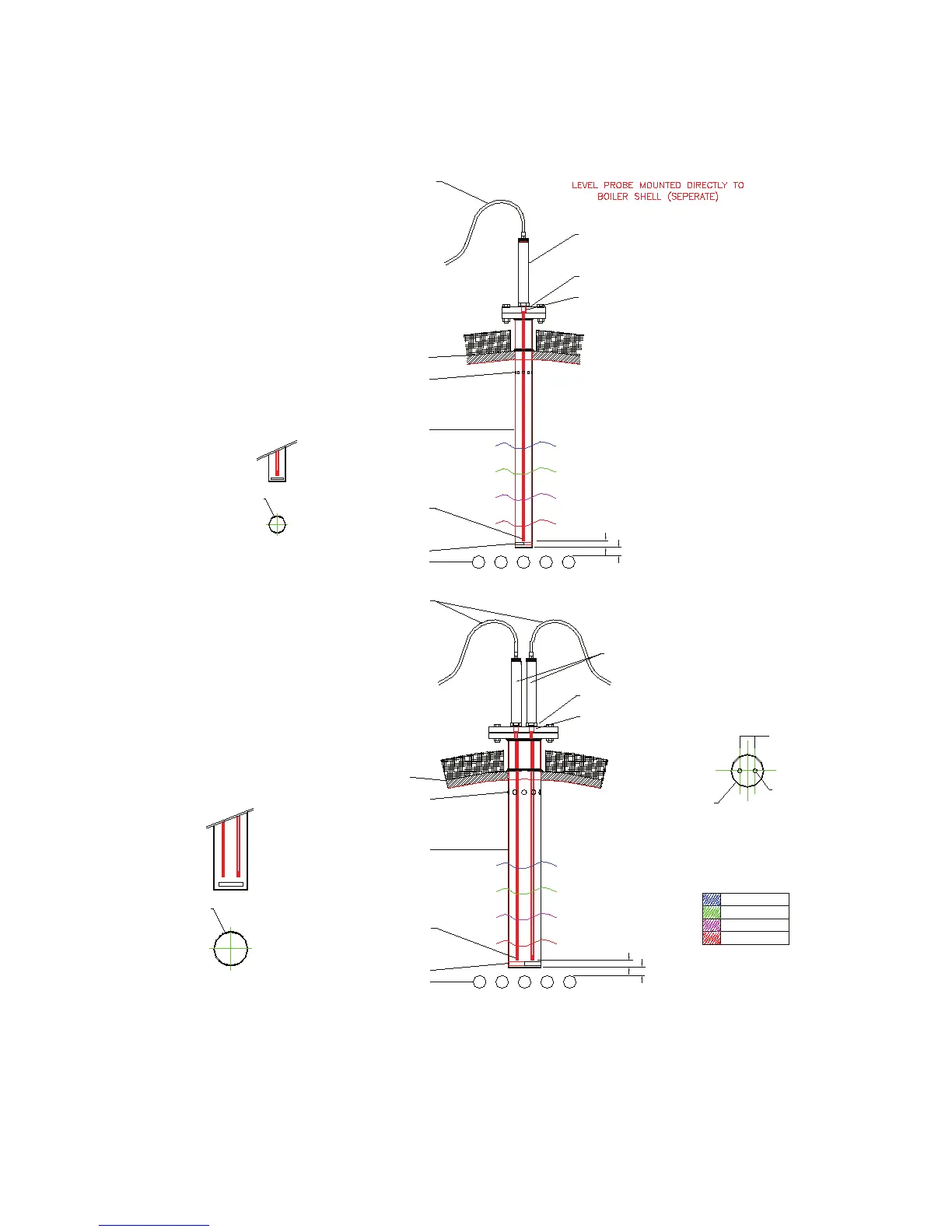

HIGH WATER

REQUIRED LEVEL

1st LOW WATER

2nd LOW WATER

BOILER TUBES

2off 18mm x 120mm SLOTS

BOTTOM 1” OF THE PROBE IS THE

SEALING PLUG AND WILL NOT

GIVE A CAPACITANCE READING

RECOMMENDED MINIMUM 6” PIPE I.D.

10x 24mm HOLES EQUSPACED AROUND 6” PIPE

BOILER SHELL

1m (3’0”) OF 10mm (0.4”) PMA SUPPLIED

1.5m OF 4 CORE SCREEN PRE-WIRED INTO THE PROBE

CAPACITANCE PROBES

INSTALLED WITH COPPER

SEALING WASHER

1/2” BSP/NPT PARALLEL THREAD

RECOMMENDED

MINIMUM 6” PIPE

TAPPING DETAIL

TAPPED 1/2” BSP

1/2” CLEARANCE FROM END OF PROBE SHROUD

1” OF CLEARANCE ABOVE BOILER TUBES

LEVEL PROBES MOUNTED DIRECTLY TO

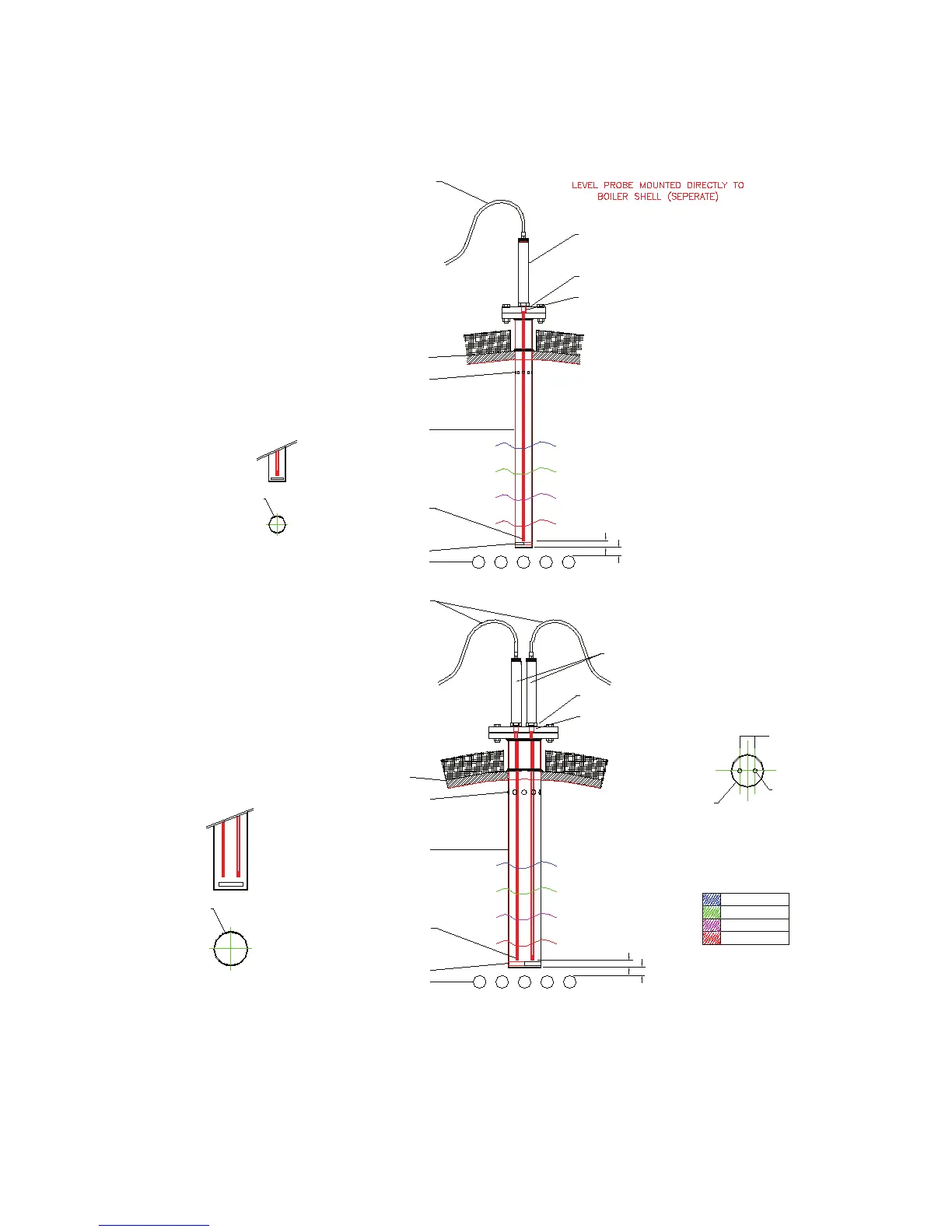

BOILER SHELL (TOGETHER)

18mm WIDE SLOT BOTH SIDES

9mm WIDE SLOT BOTH SIDES

BOILER TUBES

2off 9mm x 67mm SLOTS

BOTTOM 1” OF THE PROBE IS THE

SEALING PLUG AND WILL NOT GIVE

A CAPACITANCE READING

RECOMMENDED MINIMUM 3” PIPE I.D.

10 x 12mm HOLES EQUISPACED AROUND 3” PIPE

BOILER SHELL

1m (3’0”) OF 10mm (0.4”) PMA SUPPLIED

1.5m OF 4 CORE SCREEN PRE-WIRED INTO THE PROBE

CAPACITANCE PROBE

INSTALLED WITH SUPPLIED

COPPER SEALING WASHER

1/2” BSP/NPT PARALLEL THREAD

1/2” CLEARANCE FROM END OF PROBE SHROUD

1” OF CLEARANCE ABOVE BOILER TUBES

Loading...

Loading...