Q-7

(A)

Photoelectric

Sensors

(B)

Fiber

Optic

Sensors

(C)

Door/Area

Sensors

(D)

Proximity

Sensors

(E)

Pressure

Sensors

(F)

Rotary

Encoders

(G)

Connectors/

Connector Cables/

Sensor Distribution

Boxes/Sockets

(H)

Temperature

Controllers

(I)

SSRs/Power

Controllers

(J)

Counters

(K)

Timers

(L)

Panel

Meters

(M)

Tacho/

Speed/Pulse

Meters

(N)

Display

Units

(O)

Sensor

Controllers

(P)

Switching

Mode Power

Supplies

(Q)

Stepper Motors

& Drivers

& Controllers

(R)

Graphic/

Logic

Panels

(S)

Field

Network

Devices

(T)

Software

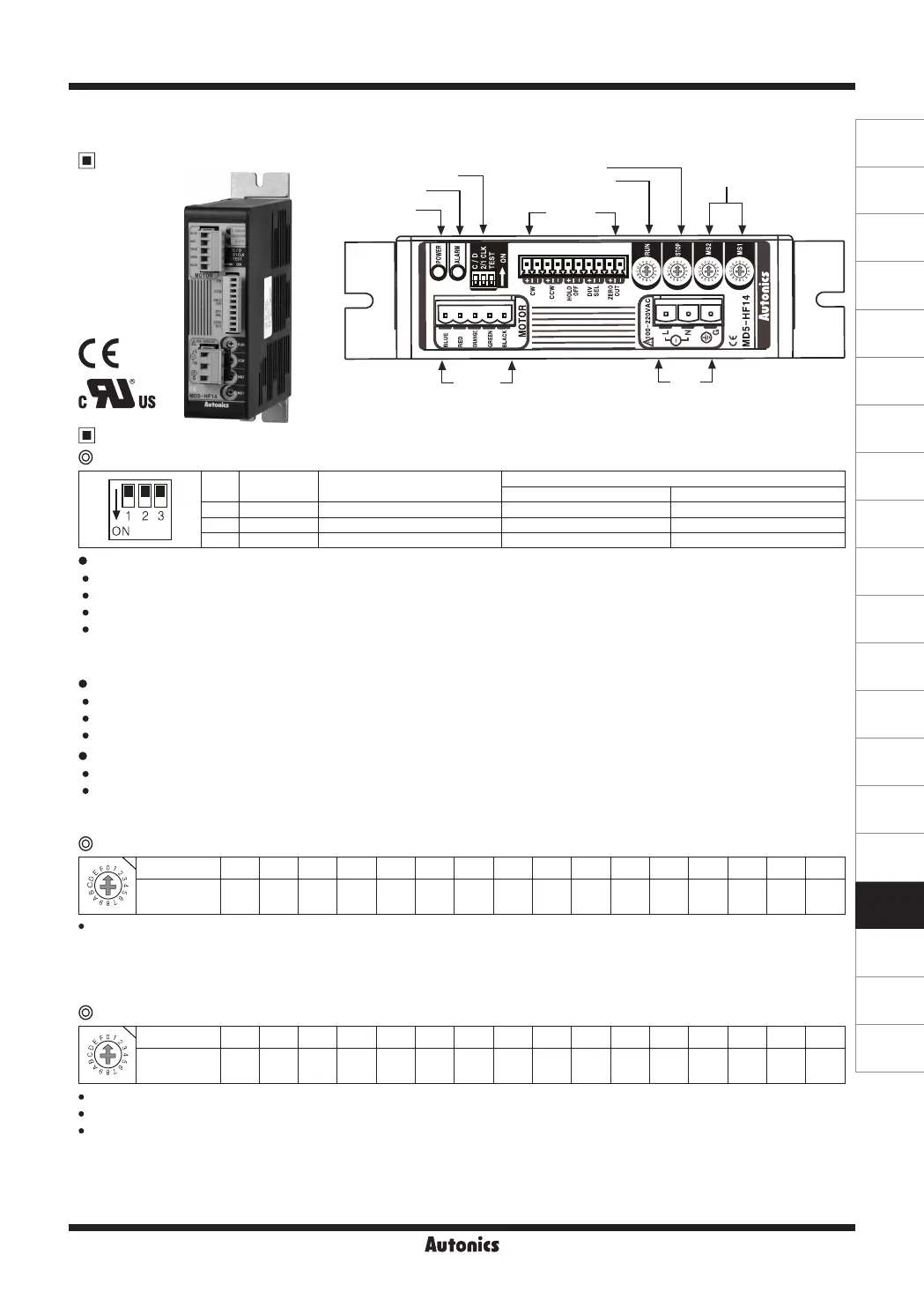

5-Phase Micro Stepper Motor Driver [MD5-HF14]

Function selection DIP switch

※

Refer to page Q-3 for the specifications.

Resolution

switch

RUN current switch

STOP current switch

Function selection DIP switch

Power indicator

Input

terminal

Alarm indicator (red)

Power

terminal

Motor

connection

terminal

Unit Description

No. Name Function

Switch position

ON OFF (default)

1 TEST Self diagnosis function 30rpm rotation Not use

2 2/1 CLK Pulse input method 1-pulse input method 2-pulse input method

3 C/D Auto current down Not use Use

TEST

Self diagnosis function is for motor and driver test.

This function makes the motor rotate with 30rpm in full step. Rotation speed varies with resolution settings.

Rotation speed = 30rpm/resolution

In 1-pulse input method, it rotates to CCW, and in 2-pulse input method, it rotates to CW.

※

Be sure that the TEST switch is OFF before supplying the power.

If the TEST switch is ON, the motor operates immediately and it may be dangerous.

2/1 CLK

2/1 CLK switch is to select pulse input method.

1-pulse input method: CW → operating rotation signal input, CCW → rotation direction signal input ([H]: CW, [L]: CCW)

2-pulse input method: CW → CW rotation signal input, CCW → CCW rotation signal input.

C/D (auto current down)

This function is to reduce the current provided for motor automatically for preventing severe motor's heat when motor stops.

If motor RUN pulse is not applied, the current provided for motor reduces as the set STOP current.

※

Be sure that when motor RUN current is reduced, the stop torque of motor also reduced.

※

Set the STOP current by the STOP current switch.

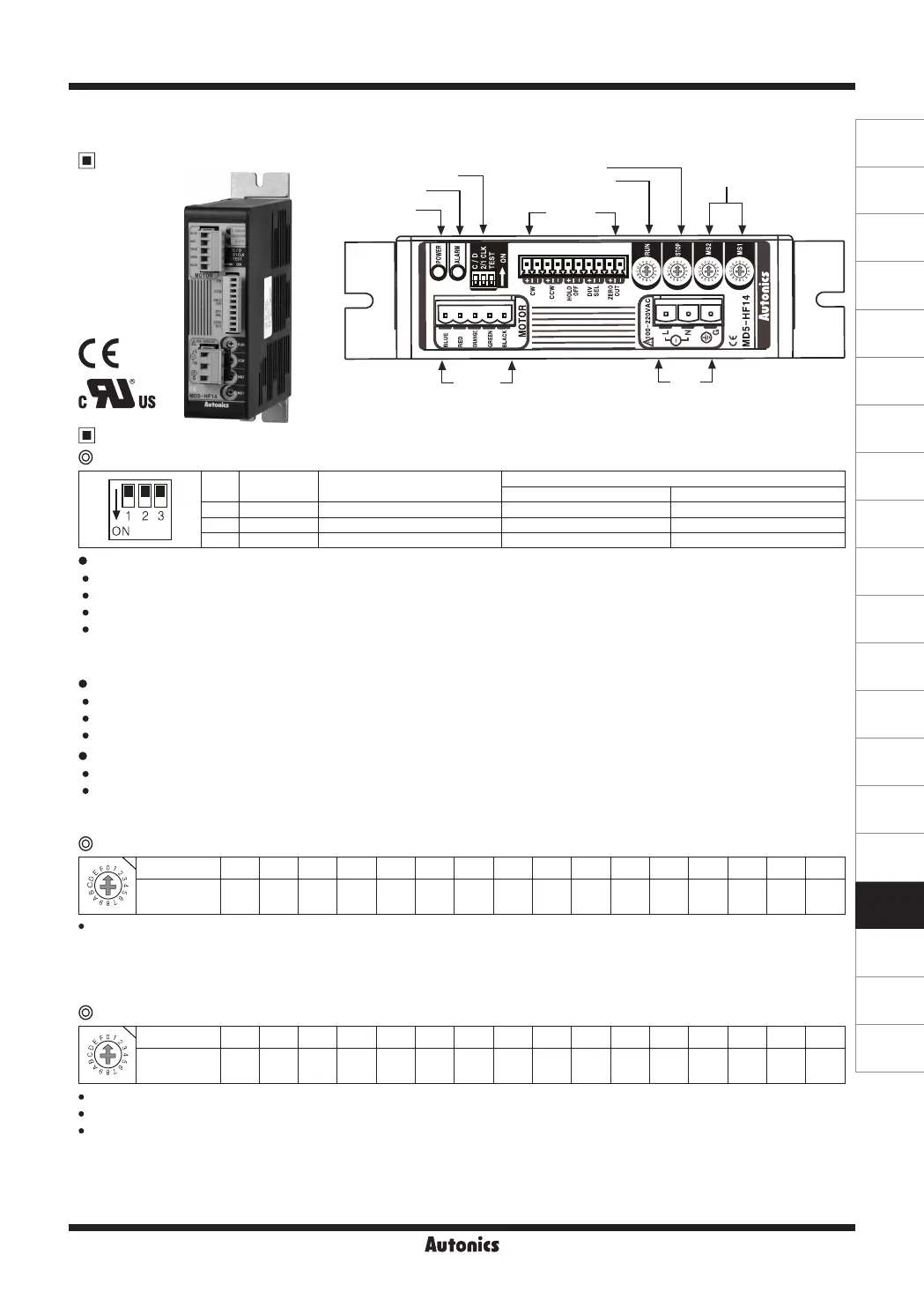

Setting RUN current

Switch No. 0 1 2 3 4 5 6 7 8 9 A B C D E F

Current

(A/Phase)

0.4 0.5 0.57 0.63 0.71 0.77 0.84 0.9 0.96 1.02 1.09 1.15 1.22 1.27 1.33 1.4

Switch No. 0 1 2 3 4 5 6 7 8 9 A B C D E F

% 27 31 36 40 45 50 54 58 62 66 70 74 78 82 86 90

Setting RUN current is for the current provided for motor when the motor runs.

※

When RUN current is increased, RUN torque of the motor is also increased.

※

When RUN current is set too high, the heat is severe.

※

Set RUN current within the range of motor's rated current according to its load.

※

Change RUN current only when the motor stops.

Setting STOP current is for the current provided for motor when the motor stops for preventing severe motor's heat.

This setting is applied when using C/D (current down) function.

Setting value of STOP current is percentage (%) ratio of the set RUN current.

E.g.) Set RUN current as 1.4A and STOP current as 40%.

STOP current is set as 1.4A×0.4=0.56A

※

When STOP current is decreased, STOP torque of the motor is also decreased.

※

When STOP current is set too low, the heat is lower.

※

Change STOP current only when the motor stops.

Setting STOP current

5-Phase Stepper Motor Driver (1.4A/Phase, AC Power)

Functions

Loading...

Loading...