22

500 Series

Tipping load

Tipping load is the load at which the rear tires lose contact

with the ground (tipping forward). Tipping load is inuenced

by several factors:

• The total load on the loader boom (attachment weight

and load combined)

• The distance of the load from the front tires

• Straight or articulated position of the loader frame

• Levelness of the ground

• Installed counterweights

• Driver presence

• Movements of the loader and the load

Overload will cause the loader to

tip forward. Always pay attention to

safe conditions operating whenever

loads or heavy attachments.

The lifting capacity and the stability of the loader are at the

best, when:

• the loader frame is kept straight

• the centre of gravity of the load is as close to the loader

as possible

• counterweights are tted to the loader

• swinging of the load is prevented and all controls are

used in a calm and careful manner

Example: If the centre of gravity of the load is 33.1 in

in front of the front axle (15.7 in from the pallet forks at

ground level), the tipping load is about 860 lb with a driver

weighting 165 lb and with the articulated frame turned to

max articulation.

If you leave the loader, tipping

and max. loads are reduced

respectively. The indicated load

is the maximum load that can be

loaded on pallet forks and the

machine will not tip over, i.e. the

weight of the standard pallet fork

attachment (210 lb (90 kg)) is

taken into account.

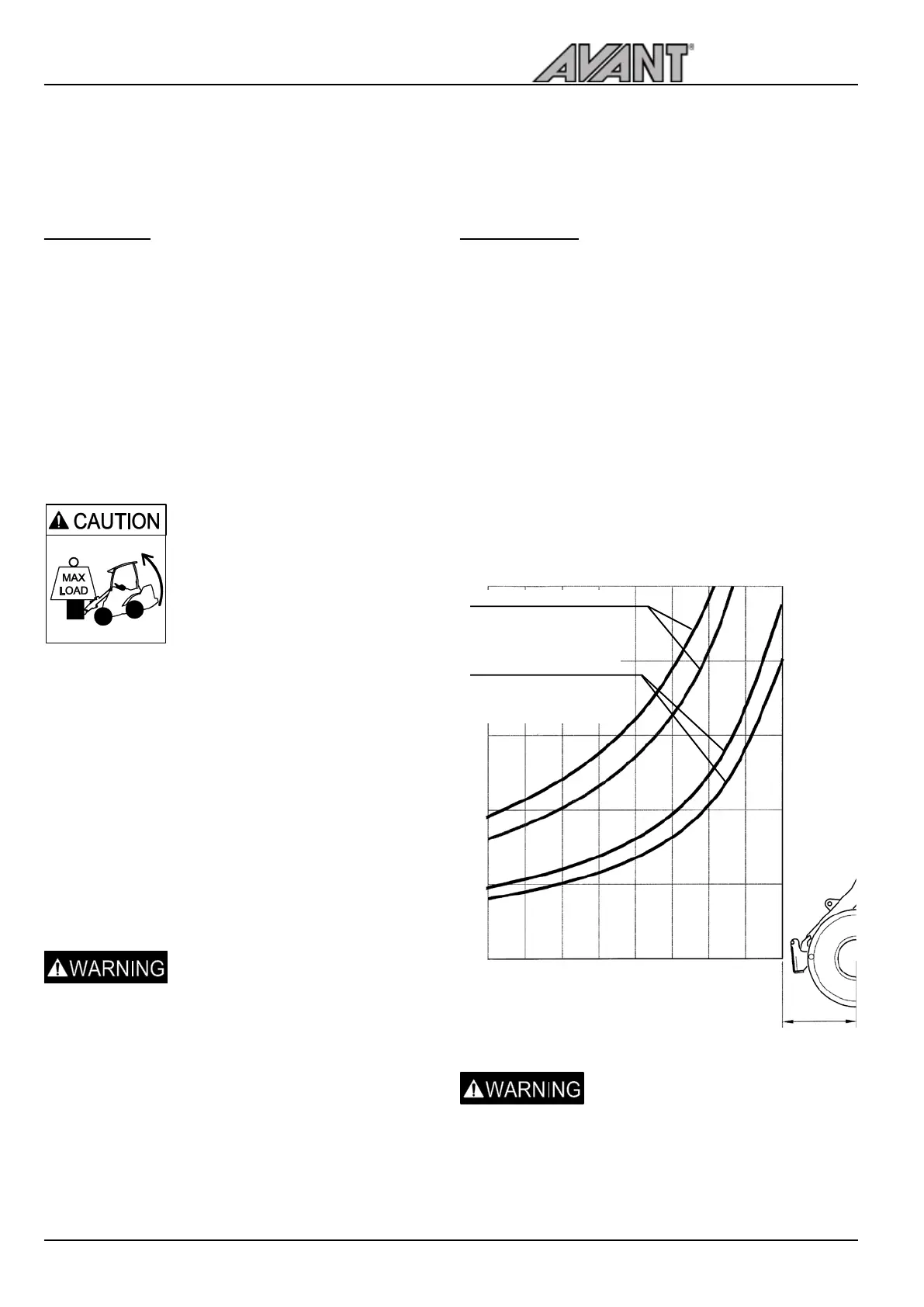

Load diagram

You can evaluate the load handling capability of the

loader with the load diagram, shown below, and the Rated

operating capacity shown on the next page and on the

label on the loader.The load handling capability depends

on the distance between the centre of gravity of the load

and the front axle of the loader.The diagram represents

the forward stability only, it does not refer to maximum

available lift force.

The load diagram below shows the tipping loads on a level

surface:

a) Tipping load with the loader frame in straight position.

b) Tipping load with the loader frame in maximum

articulation.

• ROC (Rate operating capacity), dened as 60 % of

tipping load for pallet forks.

Avoid overloading the loader

- know the load and lifting

capacity of the loader. The

diagram is valid only on rm and

level ground, with the conditions

listed above.

Tipping load with the loader

In max. articulation

Rear weight 375 lb (170 kg)

Driver 165 lb (75 kg)

Distance from front axle in inches

Rated operating capacity (ROC)

The loader In max. articulation

Rear weight 375 lb (170 kg)

Driver 165 lb (75 kg)

528 520

528

520

98.4 88.6 78.7 68.9 59.0 49.2 39.4 29.5 19.7

19.7

2750 lb

2200 lb

1650 lb

1100 lb

550 lb

Tipping load

Tipping load

Loading...

Loading...