52

500 Series

3. Greasing of the loader

Greasing of pivot points is very important to avoid wear.

Most of the greasing points are on the loader boom. The

following table and pictures show the location of grease

nipples.

Suitable lubrication interval depends heavily on operating

conditions. Check the need of lubrication at least after

every 10 hours of use. Add grease if the joints have

become dirty. Adequate lubrication of the joints must be

ensured. Lack of lubrication will cause the joints to wear

quickly.

Use general purpose machine grease. A grease gun is

needed to apply grease to grease nipples. All lubrication

nipples are standard R1/8” nipples. Replace any

damaged nipples.

Clean the end of the nipple before greasing and add only

a small amount of grease at a time. New lubricant will

push out dirt from joints. Wipe excess grease with a cloth.

Greasing points are listed in the following table.

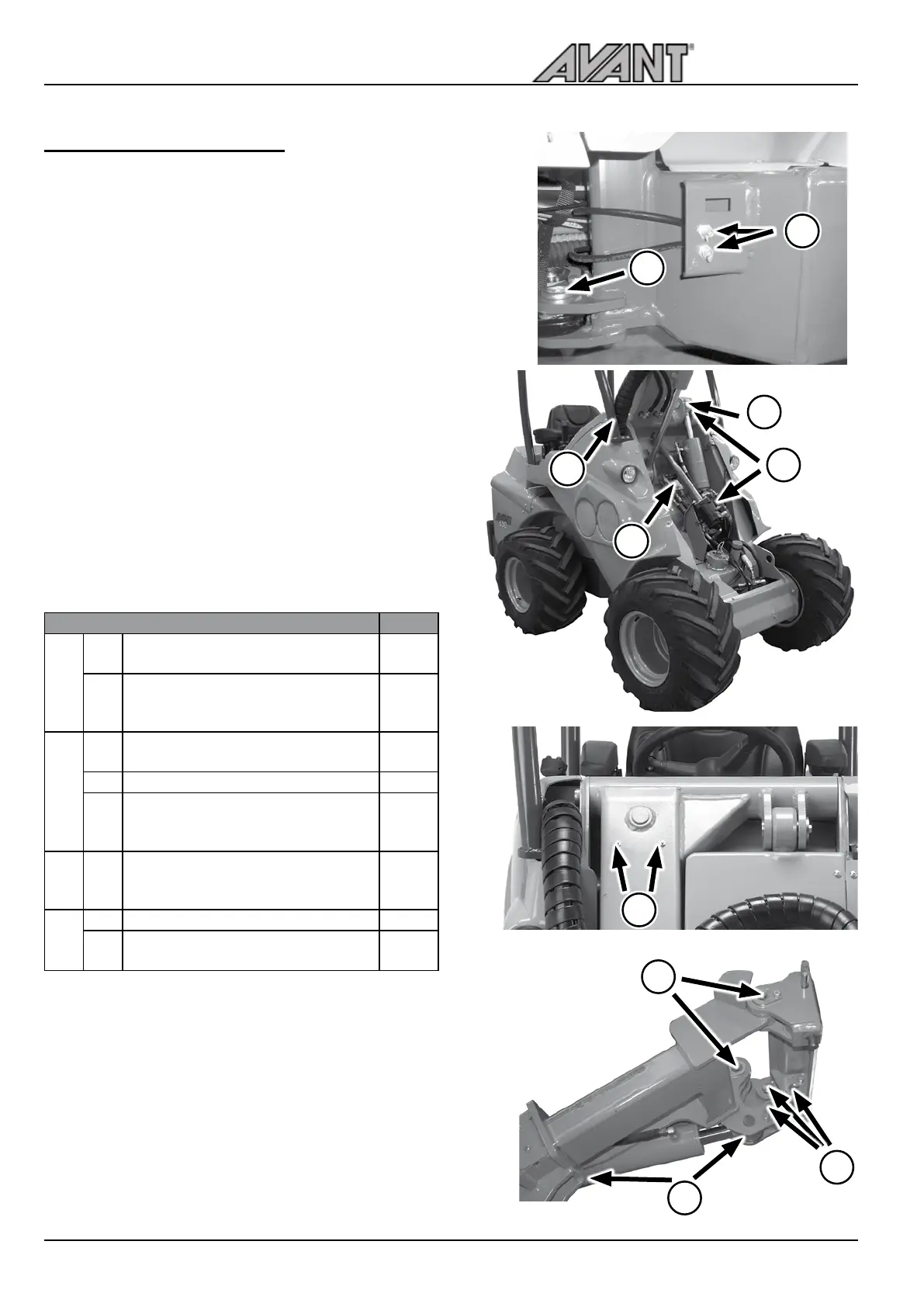

Greasing points pcs.

A

1. Articulation joint

Left side of loader

2

2. Steering cylinder

Both ends of steering cylinder, near

articulation joint

2

B

3. Boom pivot pin

Both ends of boom pivot

2

4. Lift cylinder 2

5. Leveling cylinder If tted.

Lower end accessible under front

cover.

2

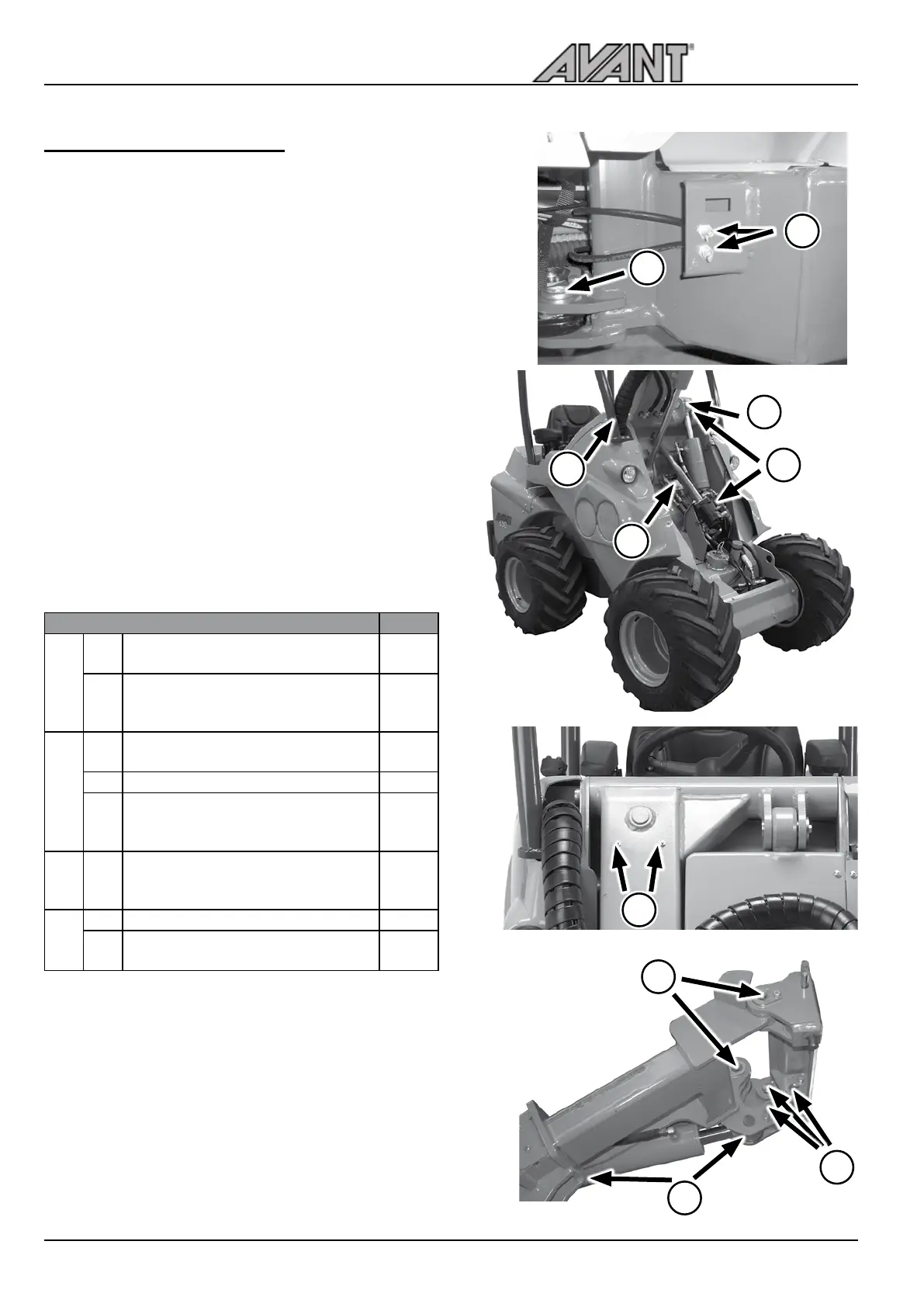

C

6. Telescopic boom

Grease when boom is completely

retracted

3

D

7. Tilt cylinder 2

8. Attachment coupling plate

Pivot pins and tilting mechanism

5

1

2

3

5

3

4

6

8

8

7

Daily inspections and maintenance

Loading...

Loading...