www.balluff.com 9english

5.1 Installation

For dimensions, see Fig.4-1 on page7.

► Fasten the module with 2M6 screws and a maximum

tightening torque of 3Nm using the mounting holes

(see Fig.4-2 on page7).

5.2 Electrical connection

Requirements for complying with the protection

classes:

For IP67, all plugs and caps must be properly connected

and the tightening torque of 0.6Nm must be observed

(see data sheets of connectors and caps).

5.2.1 Power supply

NOTICE

Unwanted voltage dips

Non-separated electric circuits of the power supplies for

sensor and actuator can lead to unwanted voltage dips

of the sensor supply when switching actuators.

► Fuse the power supplies for sensors and actuators

separately.

► Make sure that the power supply of the device is

sufficiently dimensioned to cover start-up and peak

currents and design the fuse protection concept

accordingly.

– Establish power supply of sensor/bus and

actuator via a separate power source if possible.

– The total current for the sensor and actuator

supply must not exceed 9A each.

– For UL: Observe cable requirements and power

supply requirements (see chapter8.7.2 on

page14)!

5

Installation and connection

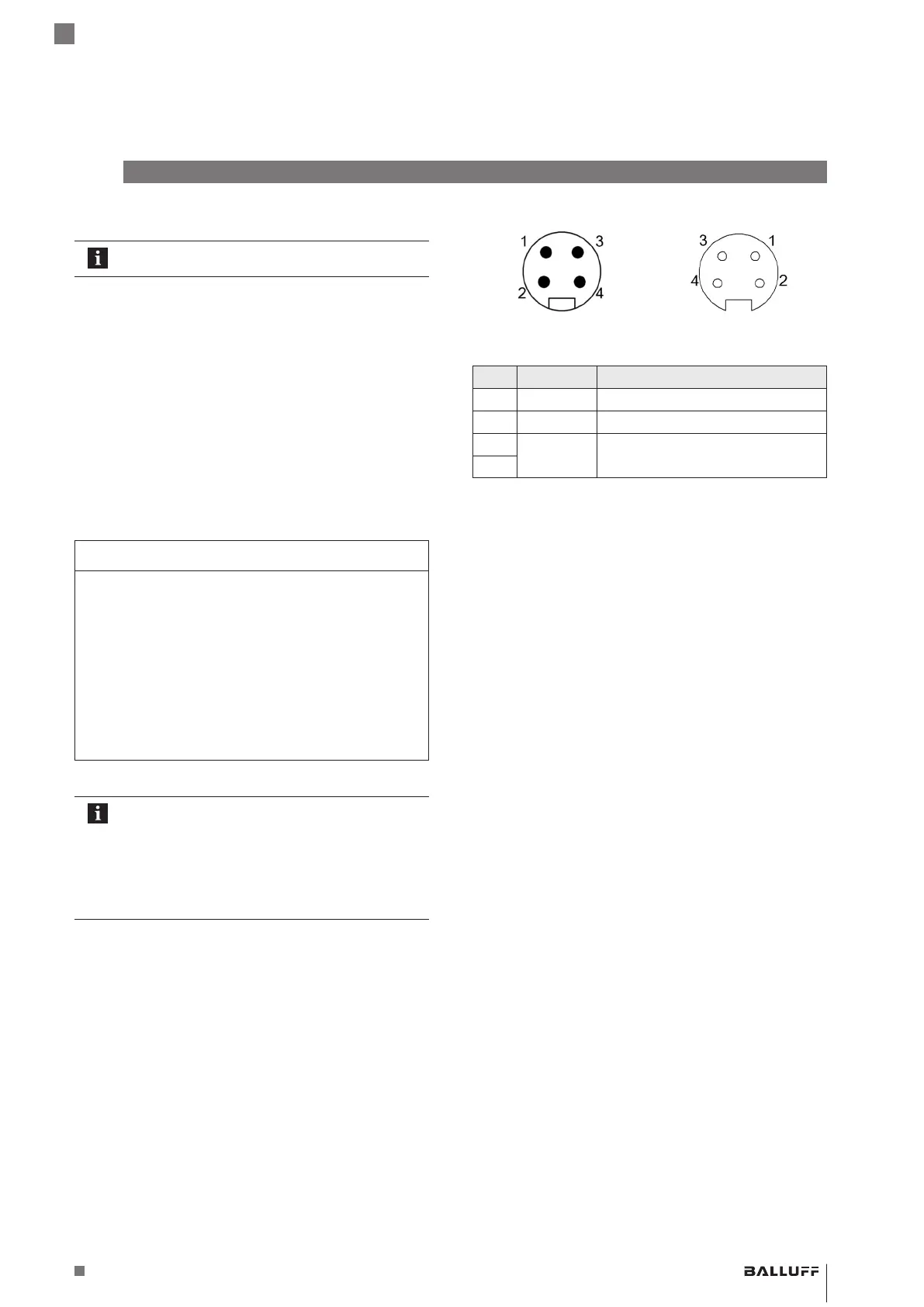

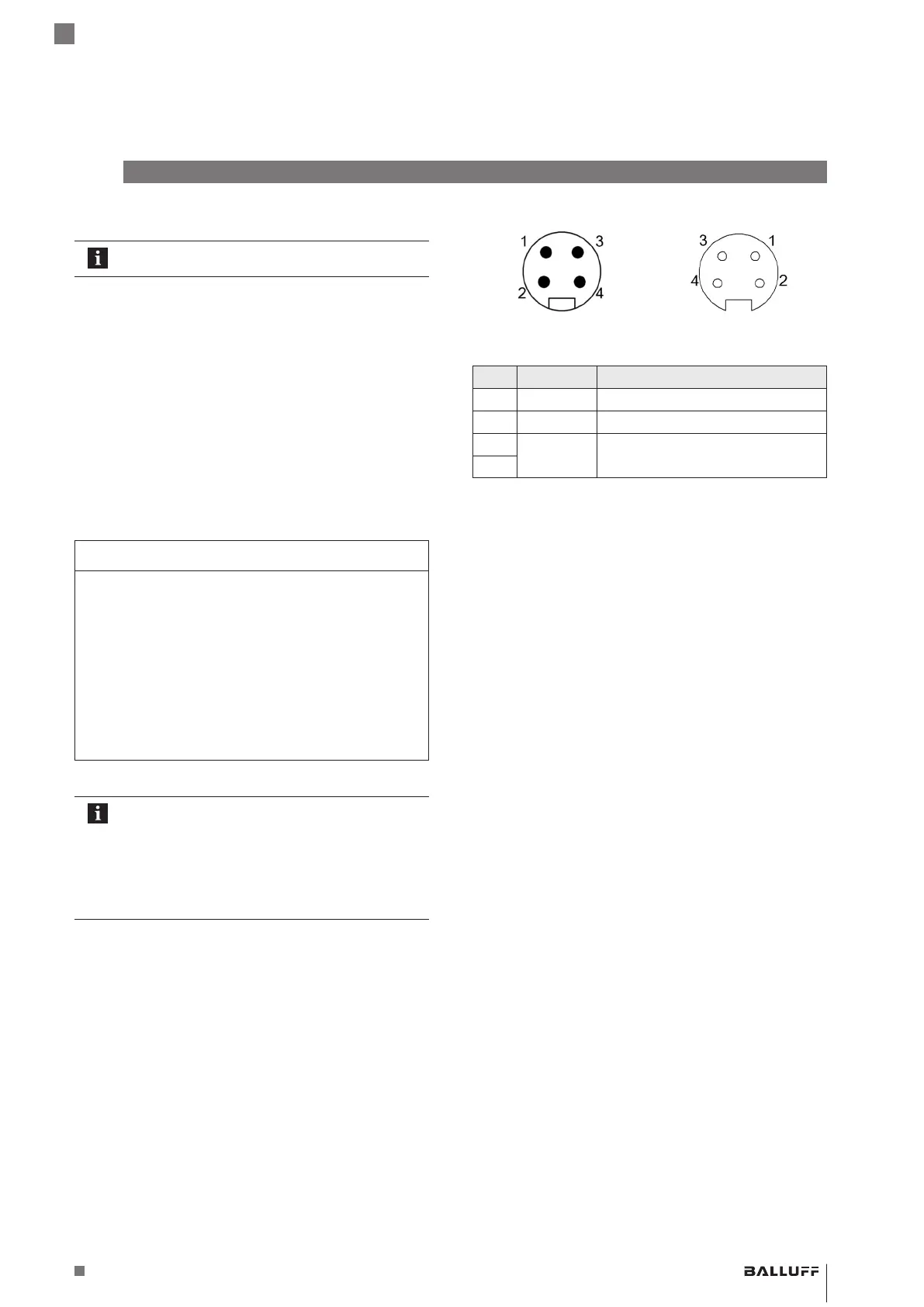

7/8" connector 7/8" socket

Fig.5-1: Top view of 7/8" plug (left) and socket (right)

Pin Signal Description

1 UA Actuator supply +24V

2 US Module/sensor supply +24V

3

GND Common ground

4

Tab. 5-1: Pin assignment

BNI EIP-508- _ 05-Z015- _ _ _

Network interface

Loading...

Loading...