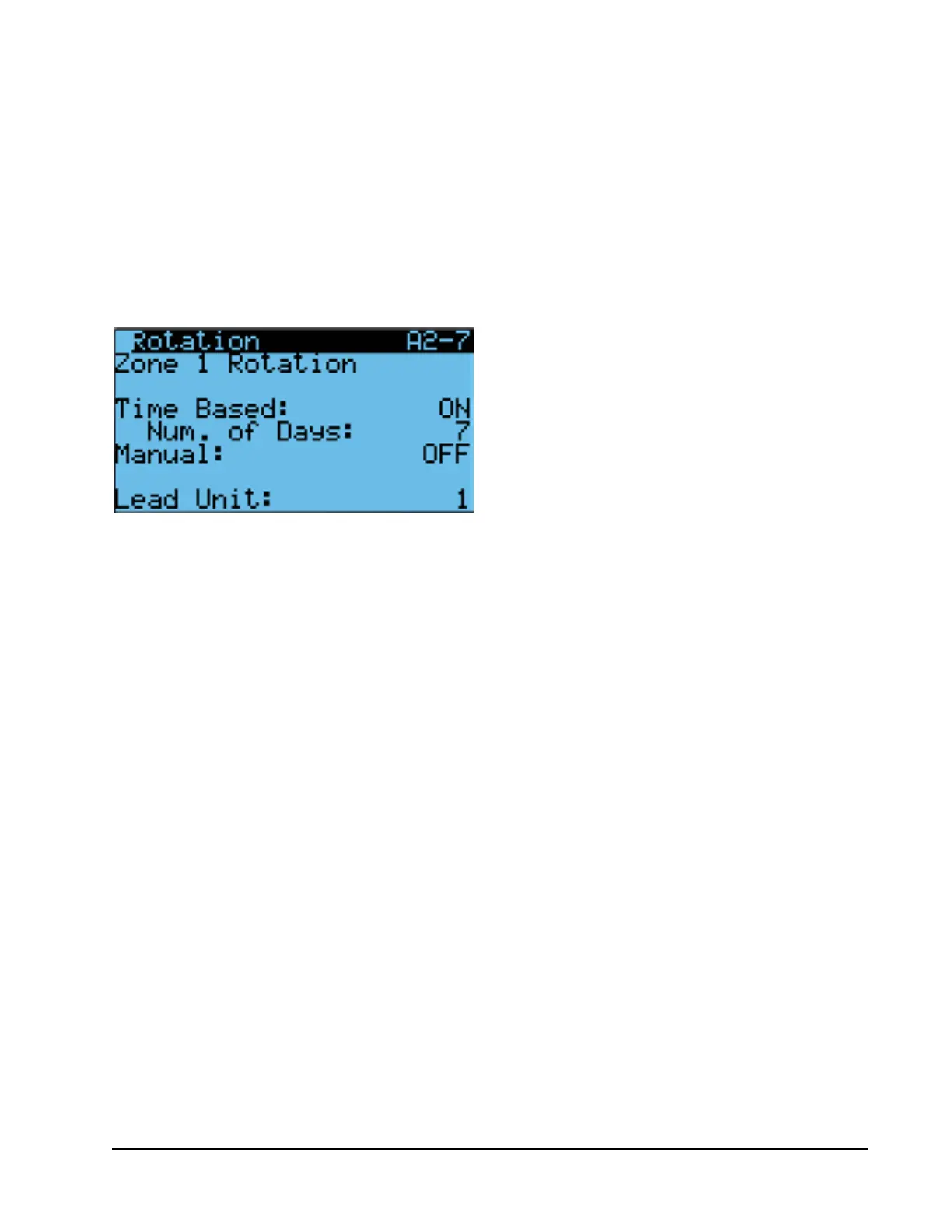

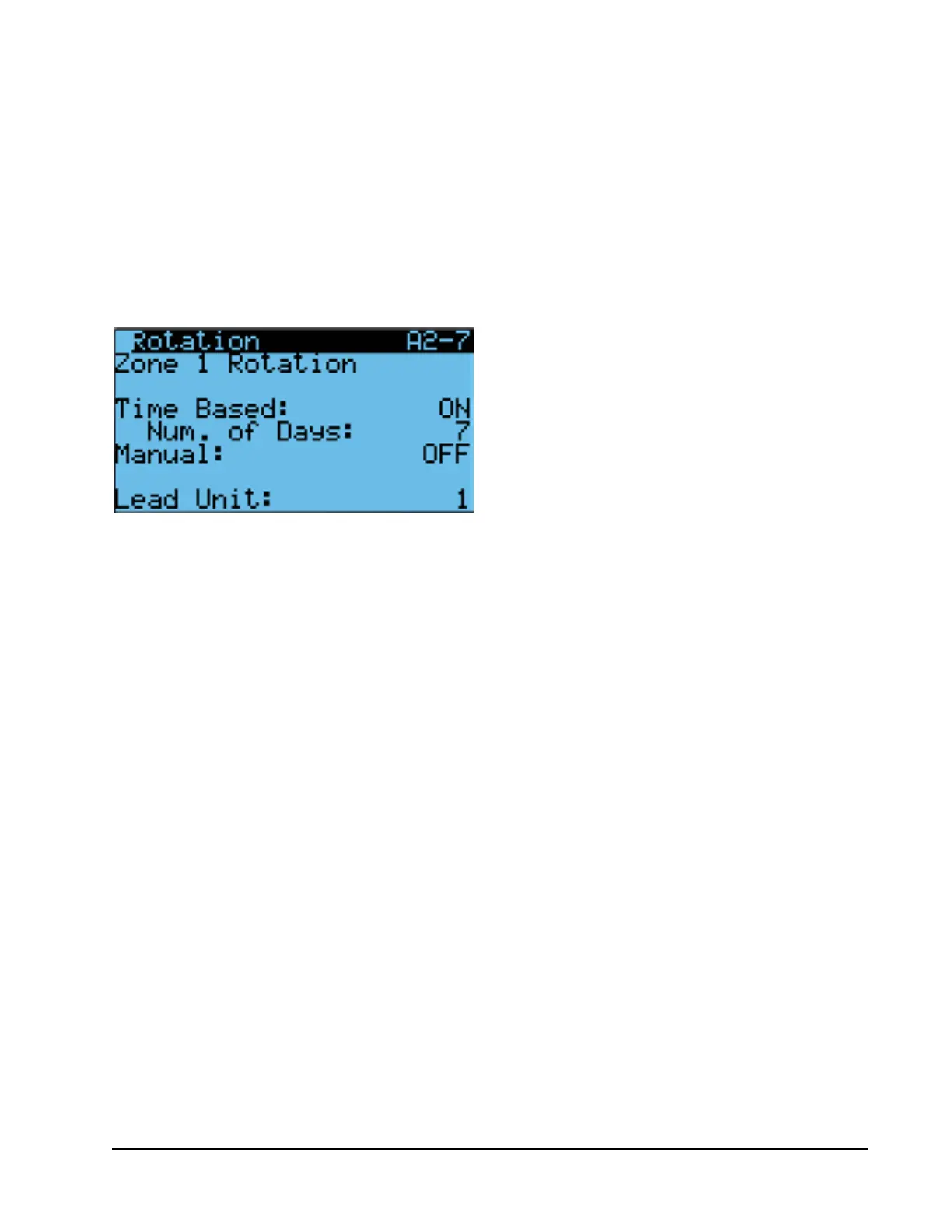

6. Press ENTER key to scroll to Time Based (see

Figure 23). The changeover time is 12 am.

7. Press UP or DOWN key to change ON to OFF.

8. Press ENTER key to scroll to Num. of Days.

9. Press UP or DOWN keys to adjust the number of

days.

10. Press ENTER key to scroll to Manual.

11. Press UP or DOWN key to change OFF to ON.

FIGURE 23

Rotation

Demand

The system will compare the zone temperature

(determined by zone averaging selection) to the

zone cooling and heating setpoint. A demand will be

calculated to determine how many units are required.

For cooling, the zone temperature will be compared

to the cooling setpoint. The controller will calculate a

demand based on how far above the setpoint and how

long it has been above the setpoint. The demand value

(0-100%) will then be split and applied to free cooling

and cooling separately shown as two demands both

ranged 0-100% applied to all of the available cooling

methods for that zone. For example, if the demand is

at 50% and there are 10 available stages of cooling in

that zone, there would be 5 stages active (50% x 10

= 5). The system will prioritize free cooling stages over

compressor stages. Adding to the example, if 5 of the

10 stages for cooling are economizer, 5 units would

be running economizer and no compressors running.

The demand is calculated for the cooling application.

However, for display purposes, the demand is split

so that the user can see demand separately for free

cooling and compressor.

For heating, the zone temperature will be compared

to the heating setpoint. The controller will calculate a

demand based on how far below the setpoint and how

long it has been below the setpoint. The demand value

0-100% will the be applied to all of the available stages

of heating in that zone. For example, if the demand is

at 50% and there are 5 available stages of heating in

that zone, there would be 2 stages active (50% x 5 =

2.5 and a half of a stage cannot be turned on).

Humidity Control

The LC can be configured to control up to three

humidifiers (field supplied) with relay outputs and

up to 14 units equipped with dehumidification. The

indoor humidity level for each zone is compared to the

dehumidification setpoint and humidification setpoint

for each zone.

Dehumidification

The LC6000 controller will monitor the indoor relative

humidity of each zone and compare the value to

three setpoints for each zone. The three setpoints

will be described as dehumidification off, passive

dehumidification and active dehumidification. The

default value for these setpoints will be 60% RH, 70%

RH and 80% RH, respectively.

When the humidity level inside the shelter falls to the

dehumidification off setpoint, the system will stop

attempting to dehumidify the space.

When the humidity level rises to the passive

dehumidification setpoint, all units with economizers

will disable the use of economizers for cooling calls.

This will act as passive dehumidification by forcing the

use of compressor for space cooling. Availability for

passive dehumidification will be determined by model

number. All units with economizers will be considered.

When the humidity level rises to the active

dehumidification setpoint, the controller will activate

staged dehumidification. The controller will then

calculate a dehumidification demand based on how

far above the setpoint and how long the RH level

has been above the setpoint. The demand will then

utilize all of the units with active dehumidification

capabilities to reduce the indoor humidity level. The

units will be staged on based on the existing cooling

rotation for the units in the zone up to an optional

maximum number of units running value. Availability

for active dehumidification will be determined by

model number. Units with concurrent electric reheat

or mechanical dehumidification will be considered.

NOTE: Only one type of dehumidification unit will

be considered depending upon configuration of the

LC6000 controller. Unit capability is determined by the

model number.

To change the dehumidification setpoints:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to Sys Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Zone 1, Zone 2

or Zone 3; press ENTER key.

5. Press UP or DOWN keys to scroll to Setpoints A2-2

(Zone 1), Setpoints A3-2 (Zone 2) or Setpoints

A4-2 (Zone 3).

Manual 2100-669F

Page 23 of 37

Loading...

Loading...