ThesystemmustbecleanedwithFernoxF3

Powerflushthesystemaccordingtothepowerflushequipmentsupplier'sinstructions.

FernoxMB1inhibitormustbeaddedaccordingtothesupplier'sinstructions.

FollowingthetreatmentprocessasampleofsystemwatermustbetakenandsenttoFernoxforanalysistoconfirmthesystemcleaninganddosingprocesshasbeen

successful.AcopyofthereporttobesenttoBaxiHeatingUKLtd,heateam,Ecogenteam,BrooksHouse,CoventryRoadWarwickCV34LL.

3.Pleasebeawareoftheresistancechartforthisappliance,andifyouarereplacingalowresistanceboilerie.oldcastiron,thesystemwillneedtoberebalanced(See

Section4).

4.Thefollowingconditionsshouldbeobservedonallsystems:

Draincocksshouldbefittedtoallsystemlowpoints.

Allgasandwaterpipesandelectricalwiringmustbeinstalledinawaywhichwouldnotrestricttheservicingoftheboiler.

Positionisolatingvalvesasclosetocirculatingpumpaspossible.

6.2TreatmentofWaterCirculatingSystems

1.Allrecirculatorywatersystemswillbesubjecttocorrosionunlesstheyareflushedandanappropriatewatertreatmentisapplied.Topreventthis,followtheguidelines

giveninBS7593"TreatmentofWaterinDomesticHotWaterCentralHeatingSystems"andthetreatmentmanufacturersinstructions.

2.Treatmentmustinvolvetheuseofaproprietarycleanser,suchasFernoxF3andaninhibitorsuchasFernoxMB1.

3.Fullinstructionsaresuppliedwiththeproducts,forfurtherinformationcontactFernox(08708700362).

Failuretoflushandaddinhibitortothesystemwillinvalidatetheappliancewarranty.

4.Itisimportanttochecktheinhibitorconcentrationafterinstallation,systemmodificationandateveryserviceinaccordancewiththeinhibitormanufacturer'sinstructions.

(Testkitsareavailablefrominhibitorstockists.)

5.ForinformationoradviceregardinganyoftheabovecontactTechnicalEnquiries08448711555.

page12

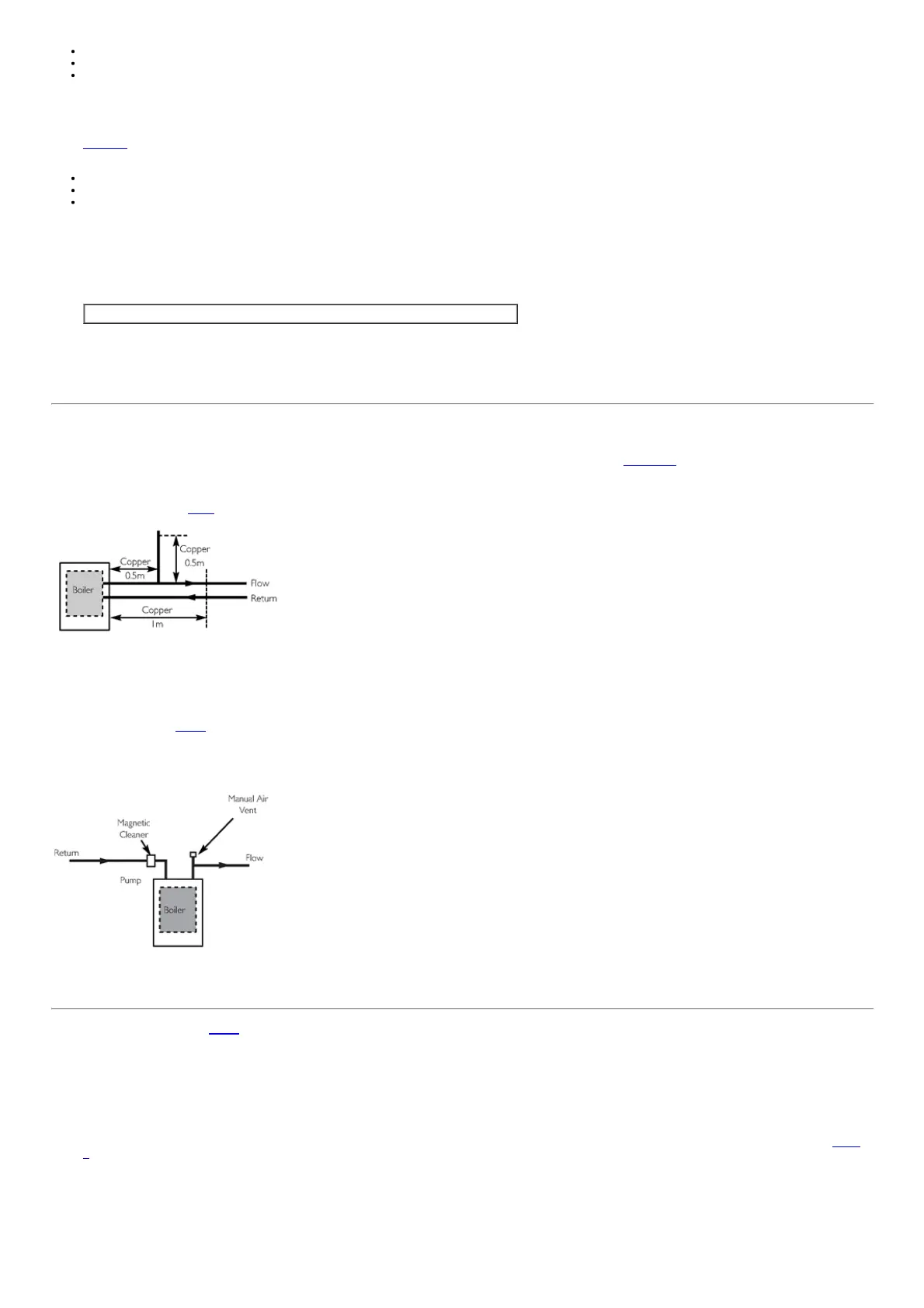

6.3Pipework

1.Thesizesofflowandreturnpipesfromtheboilershouldbedeterminedbynormalmethods,accordingtotherequirementsofthesystem.Theconnectionstotheboilerwill

accept22mmpipefittings.Compressionfittingsmustbeusedtopreventheatdamagetotheboiler(assuppliedseeSection9.3).

2.A20°Cdropintemperatureacrossthesystemisrecommendedforcondensingboilers,butwhereradiatorsizingismarginalitmaybeadvisabletoretainasystem

temperaturedropof11°C.

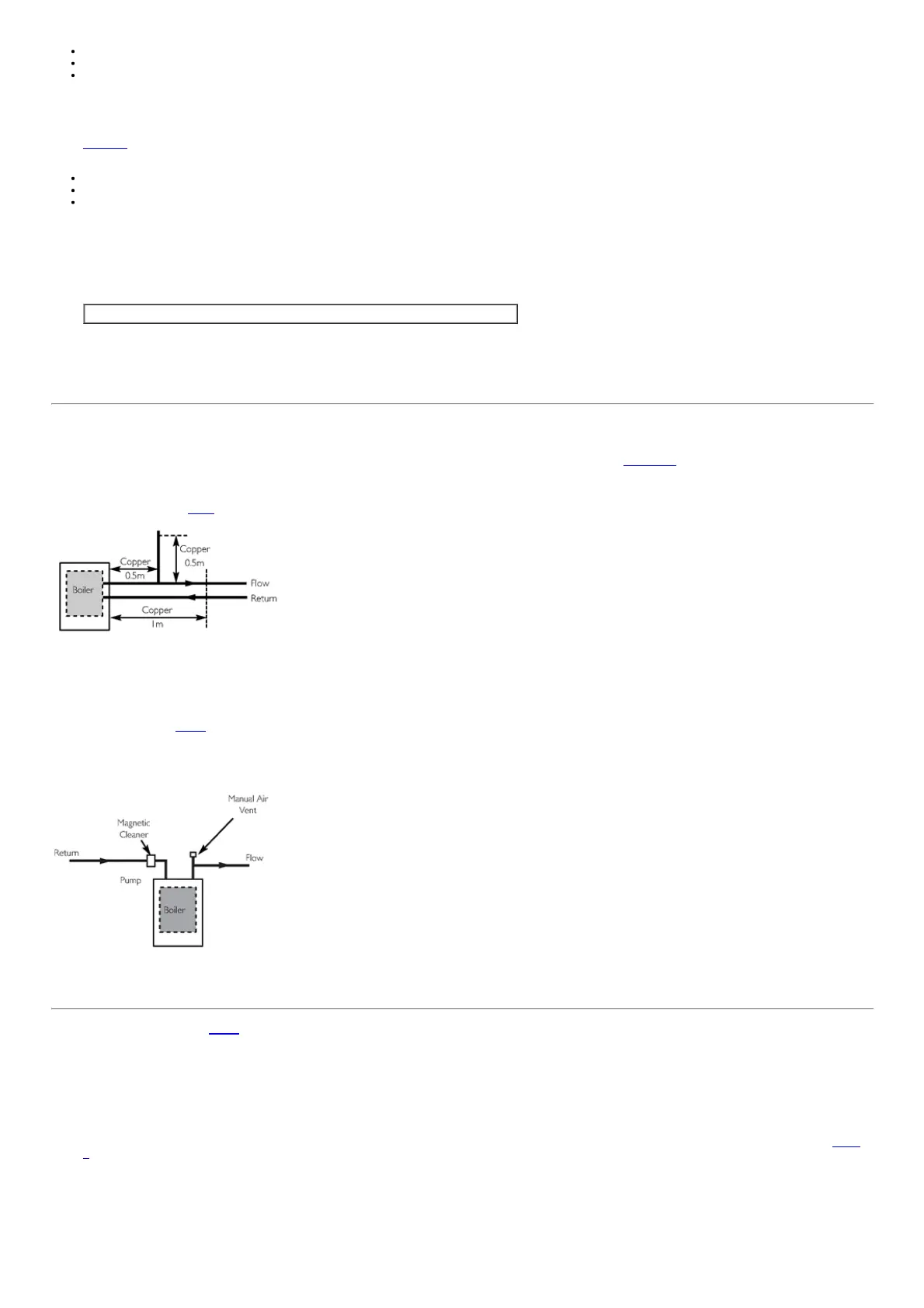

3.InsystemsusingnonmetallicpipeworkitisnecessarytousecopperpipefortheboilerFlowandReturn.Thecoppermustextendatleast1metrefromtheboilerand

includeanybranches(Fig.4).

Fig.4

6.4BypassRequirements

1.AnAutomaticBypassmustbefitted.Theappliancerequiresaminimumbypassof7l/minforopenventedsystems.

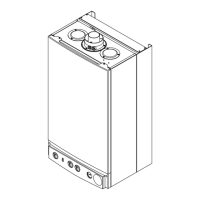

6.5MagneticCleaner(Fig.5)

1.A'ADEYMagnaCleanTwinTech'MagneticFiltermustbefittedonthereturntoboilerasclosetotheapplianceaspossible.

FAILURETOFITTHISDEVICEWILLINVALIDATETHEAPPLIANCEWARRANTY.

Fig.5

page13

6.6SealedSystemsDetails(Fig.8)

1.SAFETYVALVEAsafetyvalvecomplyingwiththerequirementsofBS6750Part1mustbefittedclosetotheboilerontheflowpipebymeansofahorizontalor

verticallyupwardconnectionwithnointerveningvalveorrestrictionsandshouldbepositionedtofacilitatetesting.Thevalveshouldbepresetandnonadjustableto

operateatapressureof3bar(45Ibf/in

2

).Itmustbearrangedtodischargeanywaterorsteamthroughapipetoasafeoutletposition.

2.PRESSUREGAUGEApressuregaugeofminimumrange04bar(060Ibf/in

2

)withafillpressureindicatormustbefittedtothesystem,preferablyatthesamepointas

theexpansionvesselinaneasilyvisibleposition.

3.EXPANSIONVESSELAnexpansionvesselcomplyingwiththerequirementsofBS4814mustbefittedtothesystembymeansofaconnectionclosetotheinletside

ofthecirculatingpumpinaccordancewiththemanufacturersinstructions,theconnectingpipebeingunrestrictedandnotlessthan15mm(1/2in)nominalsize.The

volumeofthevesselshouldbesuitableforthesystemwatercontentandthenitrogenorairchargepressureshouldnotbelessthanthesystemstatichead(SeeTable.

1).FurtherdetailsofsealedsystemdesigncanbeobtainedfromBS5449andtheBritishGaspublicationentitled'SpecificationsforDomesticWetCentralHeating

Systems'.

4.FILLINGLOOPAfillingloopconnectiononthecentralheatingreturnpipeworkmustbeprovidedtofacilitateinitialfillingandpressurisingandalsoanysubsequentwater

lossreplacement/refilling.Thesealedprimarycircuitsmaybefilledorreplenishedbymeansofatemporaryconnectionbetweentheprimarycircuitandasupplypipe

provideda'Listed'doublecheckvalveorsomeothernolesseffectivebackflowpreventiondeviceispermanentlyconnectedattheinlettothecircuitandthetemporary

connectionisremovedafteruse.Thefillingmethodadoptedmustbeinaccordancewithallrelevantwatersupplyregulationsanduseapprovedequipment.Yourattention

isdrawnto,forGB:GuidanceG24.2andrecommendationR24.2oftheWaterRegulationsGuide.forIE:thecurrenteditionofI.S.813"DomesticGasInstallations".

5.VENTINGAmethodofventingthesystemduringfillingandcommissioningmustbeprovidedbyfittingmanualvents.Caremustbetakentoensureanyairinthe

systemiscompletelyvented.

Loading...

Loading...