8.13GeneralFittingNotes

NOTE:Thefluesystemmayonlybeinstalledasdescribedinthissection

1.Cutaholeintheexternalwallwhichtheconcentricflueassemblywillpassthrough.Theholeshouldallowthefluetofallbacktotheboileratanangleof1.5°to3°.

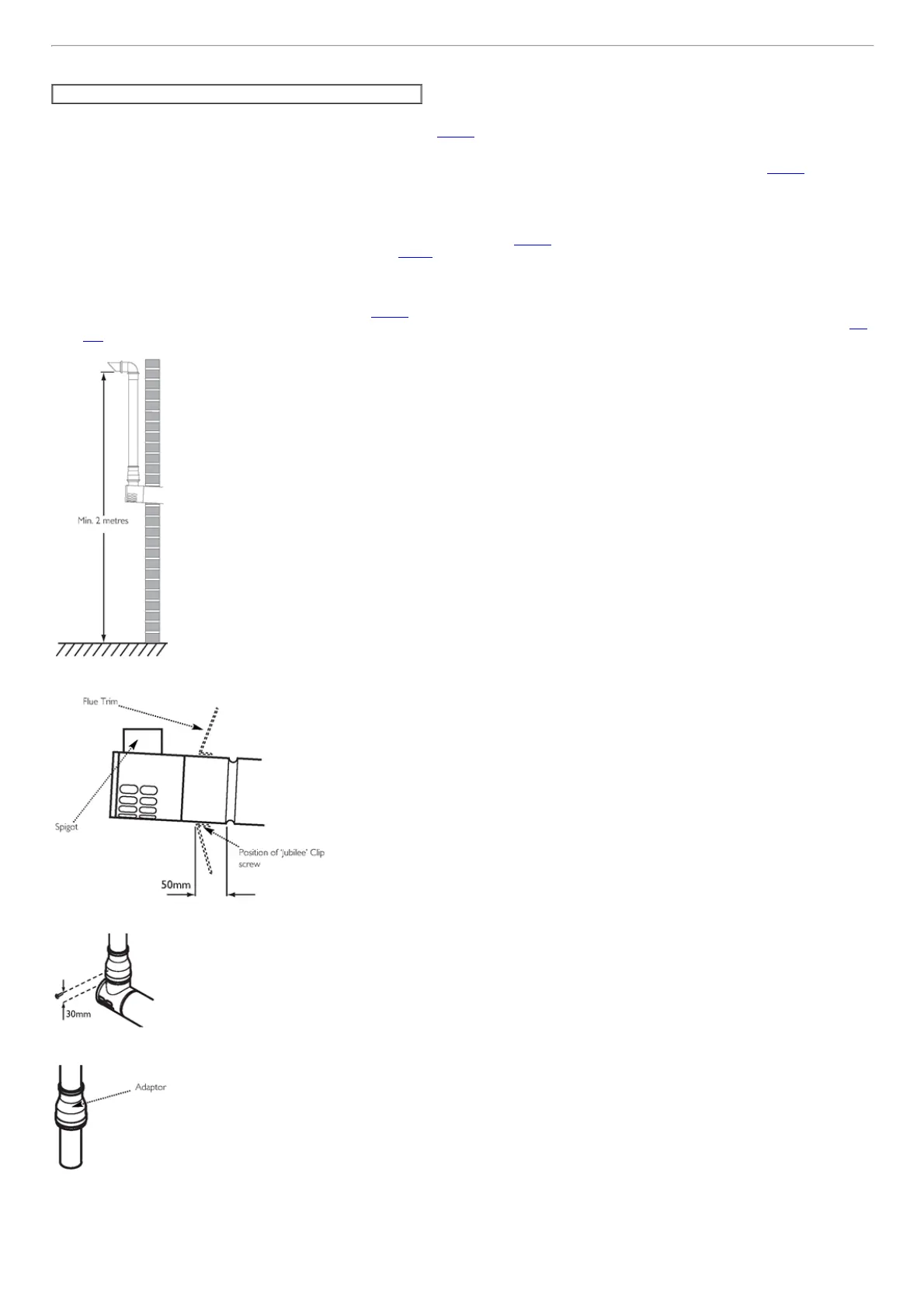

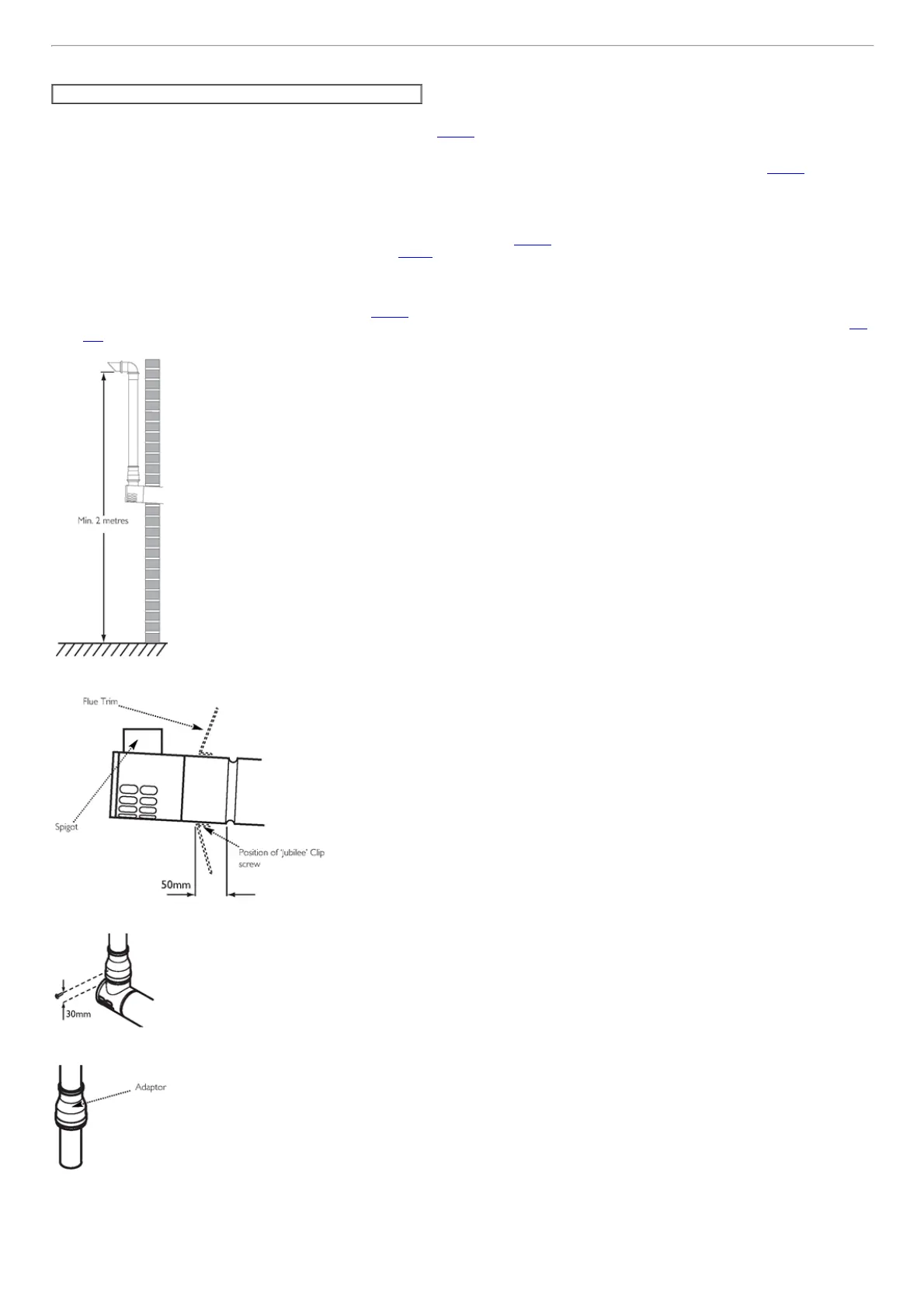

2.Whencompletedtheterminalmustbeatleast2metresabovegroundlevel(Fig.21g).

3.Measureandcuttosizetheconcentricassemblyandanyextensionsthatarebeingused.

4.Inserttheconcentricassemblythroughtheholefromoutsidethebuilding.

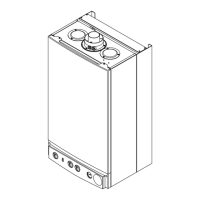

5.Ifrequired,theflexiblefluetrimshouldbefittedpriortothisasitcannotbefittedafter.Usethelarge'Jubilee'cliptosecurethetrimtotheflue(SeeFig.21h,trimshown

dotted),withthescrewpartoftheclipatthebottom.

6.Connectanyextensionsorelbowsthatarebeingusedtotheconcentricassembly.Engagetheextension,elboworconcentricassemblyintheboilerflueelbow.Fitthe

boilerflueelbowtotheboileradaptor.

7.Ensurethattheconcentricassemblyandanyextensionsfallbacktotheboileratanangleofatleast1.5°andthattheexternalairinletistothebottom.

8.Usesuitablebracketstosupporttheconcentricassemblyandanyextensions,andmakegoodinsideandoutside.

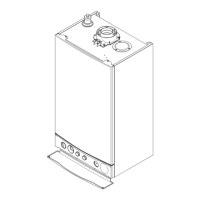

9.The60Øexhaustcannowbefitted.Slidetheadaptorovertheplainendofthe60Øexhaust(Fig.21k)andengagetheexhaustintheterminal.Slidetheadaptordownover

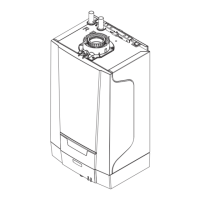

thespigot.Markanddrilltheadaptor,usinga2mmbit,asshowninFig.21j.Securetheadaptortothespigotusingoneofthescrewssupplied.

10.Ifitisnecessarytoshortenthe60Øexhaustoranyoftheextensions,theexcessmaterialmustbecutfromtheplainendofthepipe.

11.Determinethepositionofthe60Øexhaustandmarkonthewallasuitablepositionforthesupportbracket.Ifextensionsarebeingused,asupportbracketissuppliedin

eachkit.

12.Drillthewall,andfitthebracket(s)usingtheplugandscrewprovided.

13.Markanddrillthe60Øexhaust,usinga2mmbit,asshowninFig.21L.Completetheinstallationofthe60Øexhaust,securinginthebrackets.

14.Fitthe93°elbow/plumeoutletandsecurewiththetworemainingscrewssupplied.Ensuretheplumeoutletisatleast45°tothewallandthatthe'peak'isuppermost(Fig.

21m).

Fig.21g

Fig.21h

Fig.21j

Fig.21k

Loading...

Loading...