Alaris™ GP (Guardrails™) Volumetric Pump

Alarms

BDDF00535 Issue 1

33/56

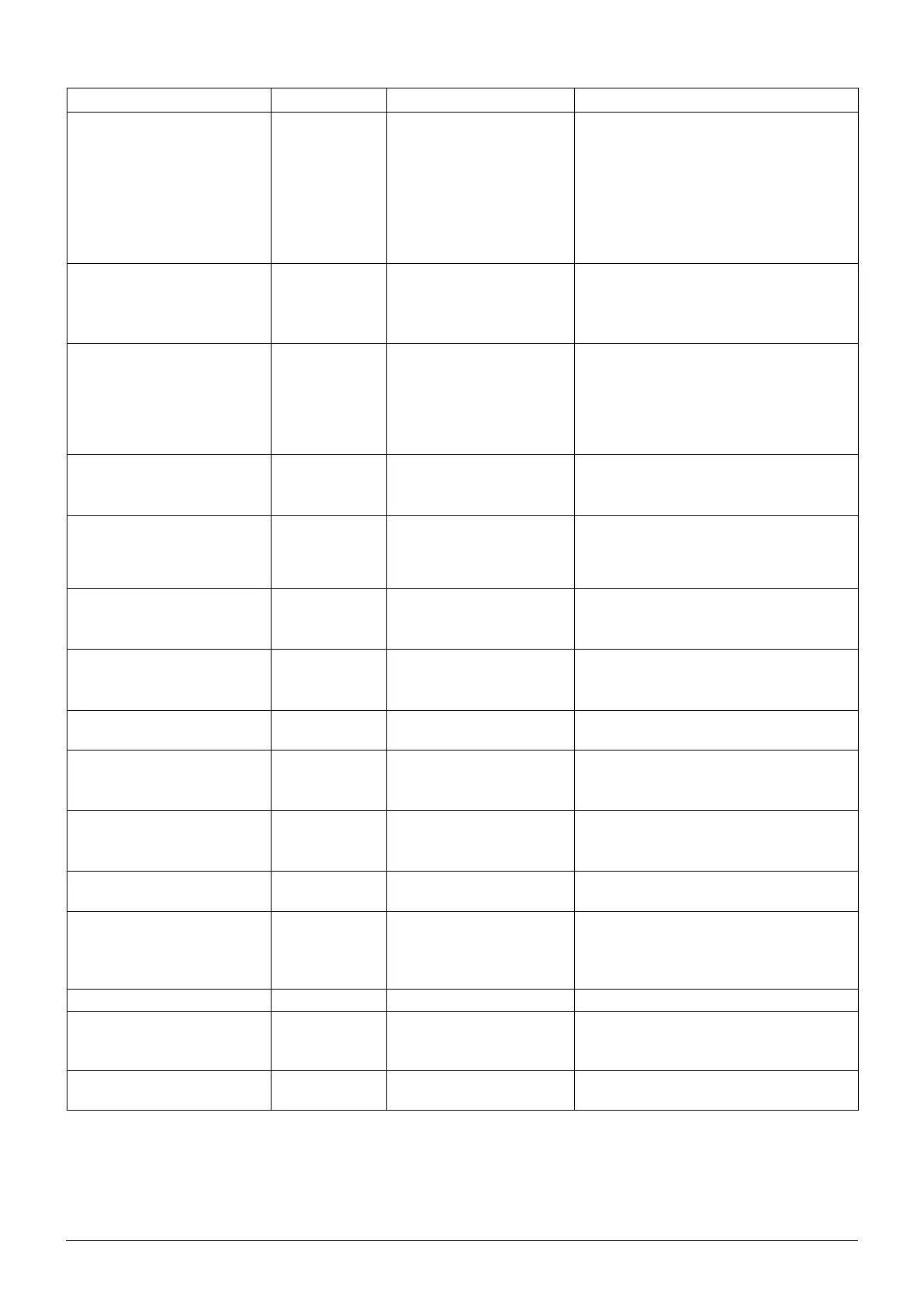

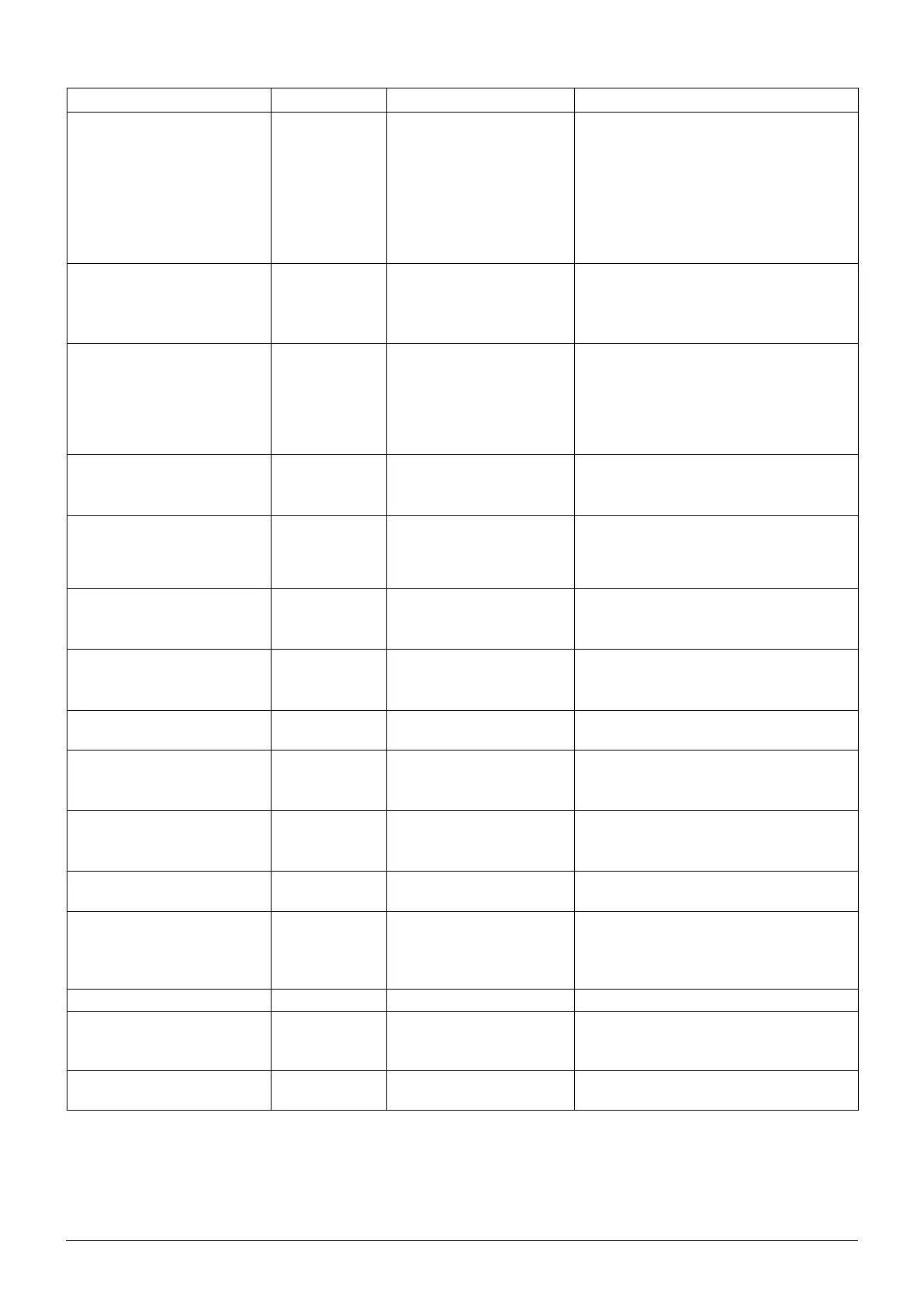

Display Infusion Status Cause(s) Action

NO FLOW Infusion stopped Flow sensor detects no flow.

• Check flow sensor.

• Check fluid level in container.

• Ensure all clamps above Pump are

open.

• Ensure drip chamber is half filled.

• Ensure that the bag spike is inserted

correctly.

• Check flow sensor is clean.

FLOW ERROR Infusion stopped

Gross difference between

detected drops and expected

amount of drops.

• Clamp infusion set using roller clamp.

• Check flow sensor.

• Check fluid level in drip chamber.

FLOW ERROR (In secondary

infusion mode only)

Infusion stopped Unexpected drops detected.

• Hang secondary container above

primary.

• Check drops are from secondary

container when infusing.

• Flow sensor disconnection is

recommended.

FREE FLOW Infusion stopped Uncontrolled flow possible.

• Clamp infusion set using roller clamp.

• Remove Pump from use.

BATTERY EMPTY Infusion stopped

The internal battery is

exhausted. The Pump will

automatically switch off in the

immediate future.

• Connect to power supply immediately

or switch Pump off.

SAFETY CLAMP Pump on hold

Safety clamp broken or

missing.

• Clamp infusion set using roller clamp.

• Replace infusion set.

• Investigate and correct set loading.

SET MISLOAD Pump on hold Set loaded incorrectly.

• Clamp infusion set using roller clamp.

• Investigate and correct set loading.

FLOW SENSOR DISCONNECT Infusion stopped

Flow sensor unplugged

during infusion.

• Check / replace flow sensor or set VTBI.

WRONG SET Pump on hold Safety clamp not detected.

• Clamp infusion set using roller clamp.

• Check set and close door.

• Replace infusion set (If necessary).

DOOR CLOSE INCOMPLETE Pump on hold

Safety clamp in non-occluded

position with door open or

obstructed.

• Clamp infusion set using roller clamp.

• Investigate and correct set loading.

• Close door.

DO NOT USE

Pump on hold /

infusion stopped

Internal error has occurred. • Remove Pump from use.

LEVER OPEN Infusion stopped Door lever is open

• Check door lever.

• Check lever hooks.

• Check lever is not obstructed, if so, free

obstruction.

VTBI DONE Infusion stopped Intended VTBI completed. • Set new VTBI or clear VTBI.

SET CLOCK Pump on hold Date / time not set.

• Qualified Service Personnel must set

date / time.

• Press CANCEL softkey to continue.

SET SERIAL NUMBER Pump on hold Serial number not set.

• Contact Qualified Service Personnel to

set the serial number.

Loading...

Loading...