M10

Instruction Manual

52

7 TROUBLESHOOTING

7.1 MALFUNCTIONING AND POSSIBLE SOLUTIONS

The following table summarizes the possible malfunctions that may occur during the use of the M10 meter,

for which the possible causes and solutions to be adopted in order to restore correct operation of the

flowmeter are listed.

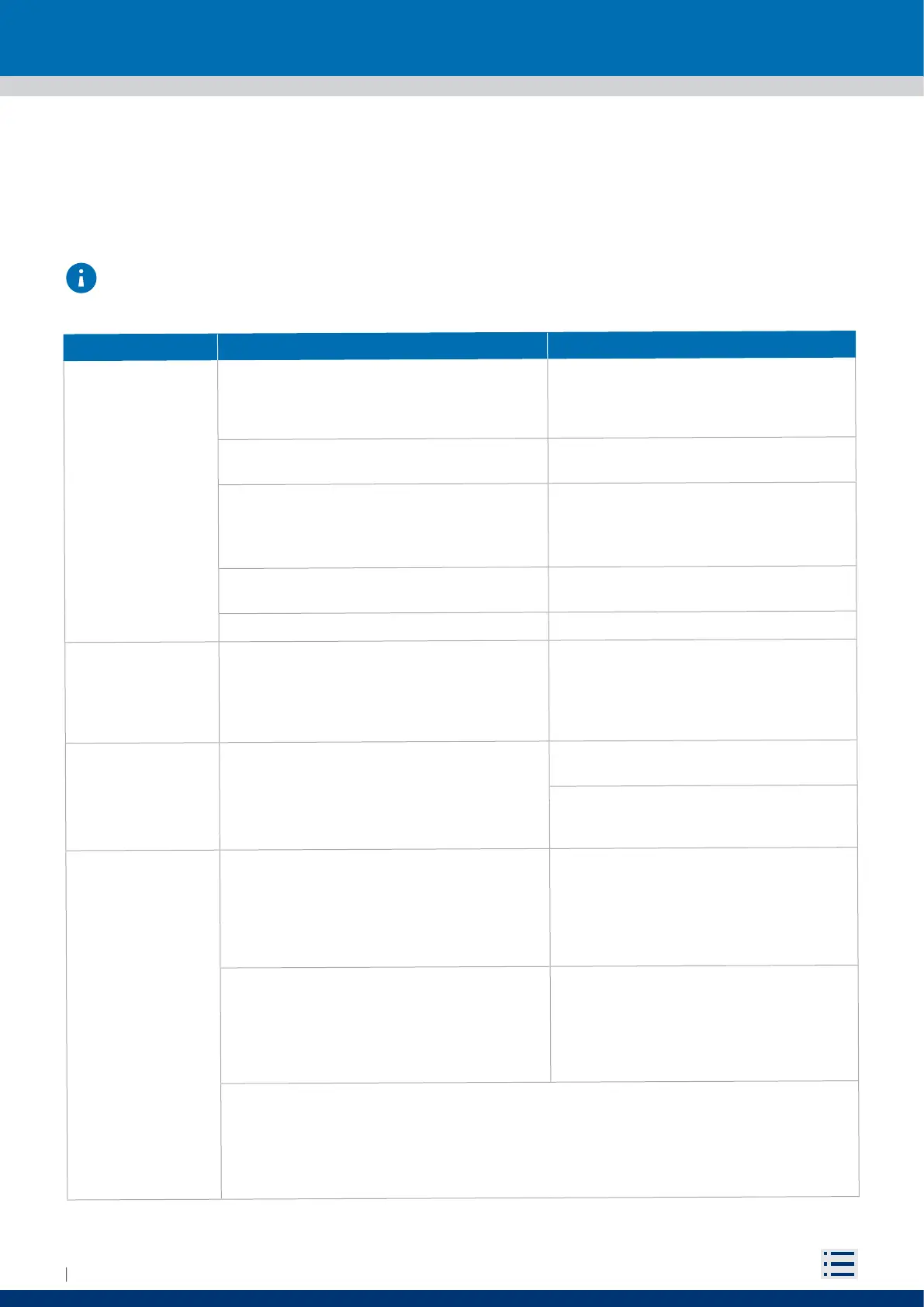

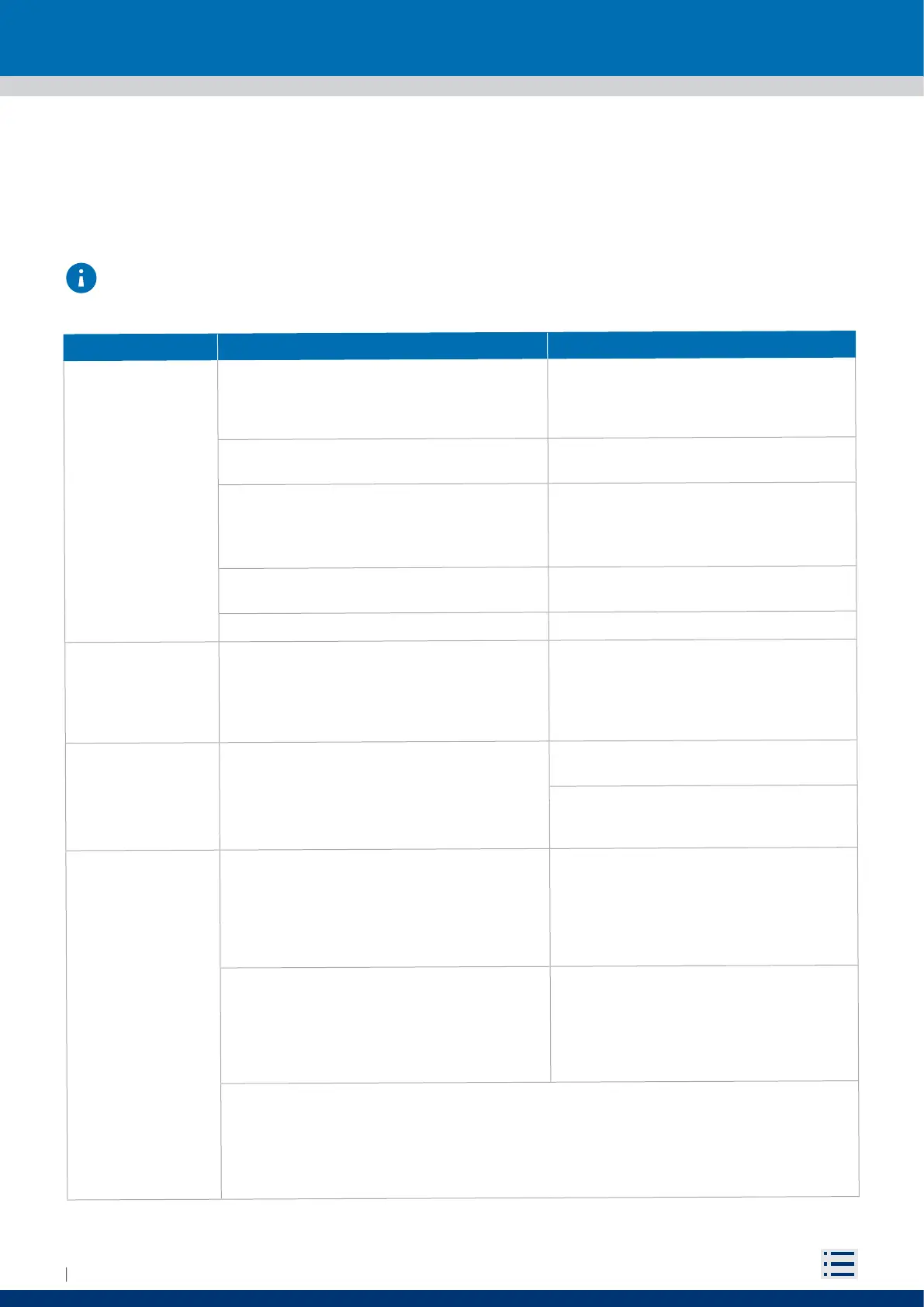

MALFUNCTIONING POSSIBLE CAUSE SOLUTION

The meter shows

a flow rate even

when there is no

flow.

Grounding missing or incorrect. Check that the meter and the liquid are

correctly grounded, making sure that the

relative earth ground connections are

correctly connected.

Lack of liquid in the sensor downstream of

the converter.

Check that the sensor is full of liquid.

Electric conductivity of the liquid is too low,

or it is not compatible with the material

used for the sensor electrodes.

Check which electrode type is used on

the sensor.

If necessary, replace electrodes and/or

sensor.

Missing or incorrect “zero calibration”. Perform manual zero calibration if

necessary.

Cut-o filter value is too low for the process. Increase filter value.

External pulse

totalizer shows

results dierent

than expected.

Pulse output configuration error. Check the pulse volume and pulse

duration settings.

Simulate a flow rate through System >

Simulation and test the output using a

pulse counter.

The screen is

turned o and it

doesn’t turn on.

There is no voltage supply, or it is incorrect. Mains powered: Check the power supply

is 12Vdc

Battery powered: check the battery

life and correct installation, replace the

battery pack.

The flow reading is

very unstable.

Hydraulic nature:

Air bubbles/pockets or unstable flow (vortex

motion). The minimum required linear

distances upstream and downstream of the

device were not complied with.

Check for the presence and correct

installation of vents on the pipe to avoid

the presence of air in the pipe.

Check for the minimum required linear

distances upstream and downstream of

the device.

Electrical nature:

Grounding missing or improperly made,

oxidized nodes, very noisy ground point,

usually in common with the grounding

systems of pumps or inverters, liquid

conductivity is too low.

Change the grounding point or preferably

create a new one for the exclusive use

of the meter.

NOTE: If with full pipe and stable liquid an unstable reading can be observed

(which varies rapidly) then most likely it is a problem of electrical noise.

Only if necessary, set the filters in the following way:

Set the “damping” to 150

Reduce the “peak cut o” filter

Increase the “bypass” filter

Loading...

Loading...