42

CONTROLS ADJUSTMENT

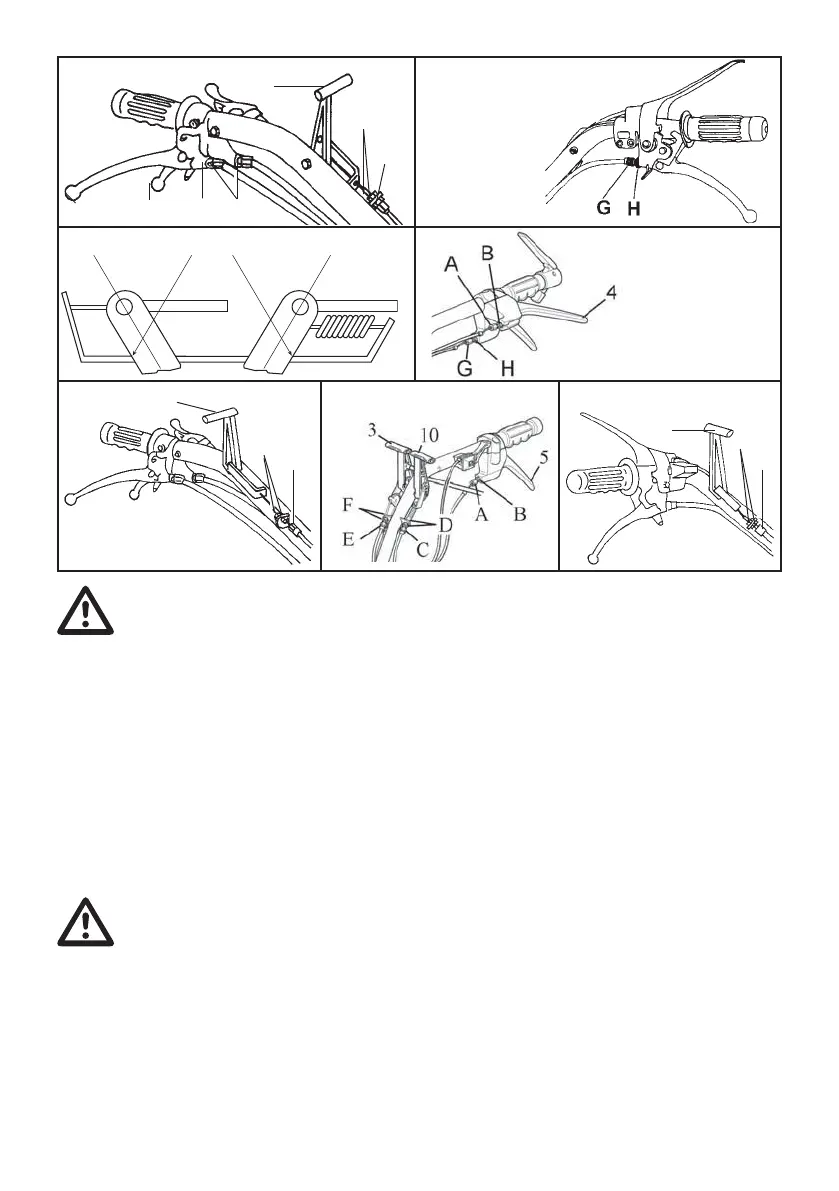

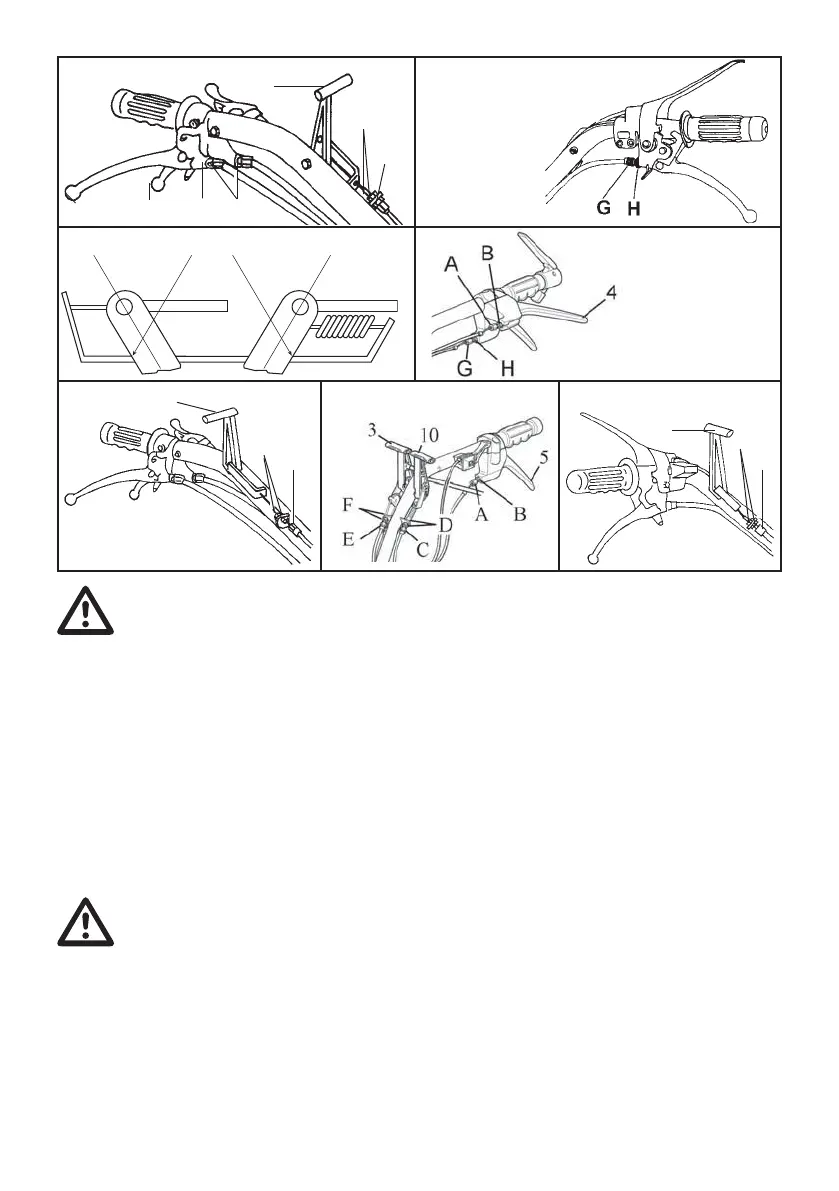

BRAKES (141)

The wheels must be locked when levers 4 and

5 (Fig. 14 - 15A - 16A) are engaged. If this is not

the case, loosen nuts B and then set adjuster A.

When adjustment is obtained lock nuts B again.

REVERSING GEAR CONTROL LEVER

(Fig. 14 - 16A e 14/1)

Check that the reversing gear lever on the

gearbox strikes against the plate as shown in

reference A, in forward speed and against plate

in reference B in reverse speed.

Use adjuster C and nuts D to adjust stroke.

ATTENTION: An incorrect position of

references A and B could CAUSE

DAMAGE TO THE GEARBOX.

CLUTCH

Check the idle stroke of the clutch lever regularly.

This should be approximately 5mm.

In order to change adjustment, loosen nut H

(Fig. 15 - 15A).

Screw or unscrew adjuster G until stroke is

approx. 5 mm, then lock nut H again.

DIFFERENTIAL LOCK (141)

If the differential lock is still engaged when

lever 3 (Fig. 16 - 16A) has been put in idle,

obtain proper adjustment by using adjuster E

and nuts F.

QUICKFIT SHUTTER

LOCK/UNLOCK LEVER

If by pulling lever 11 (Fig. 17), the implement

is not released, then set adjuster L and nuts I.

AIRBORNE NOISE

Acoustic pressure recorded at 1,6 m off the

ground in the centre of the handlebars by a B

& K 2230 instrument facing the engine.

Maximum level of acoustic pressure statistically

weighted equivalent:

90.7 dB (A)

Sound Power: 104.6 dB (A)

HANDLEBAR VIBRATION

Statistically weighed measurement in

accordance with ISO 5349: 16,2 m/sŸ2

Data refers to maximum values recorded with

the range of engines available.

Fig. 16

A

Fig. 14

54

B

10

C

D

Fig. 14/1

Fig. 15

A

B

3

E

F

Fig. 15/A

141M

Fig. 16/A

Fig. 17

11

L

I

141M

Loading...

Loading...