48

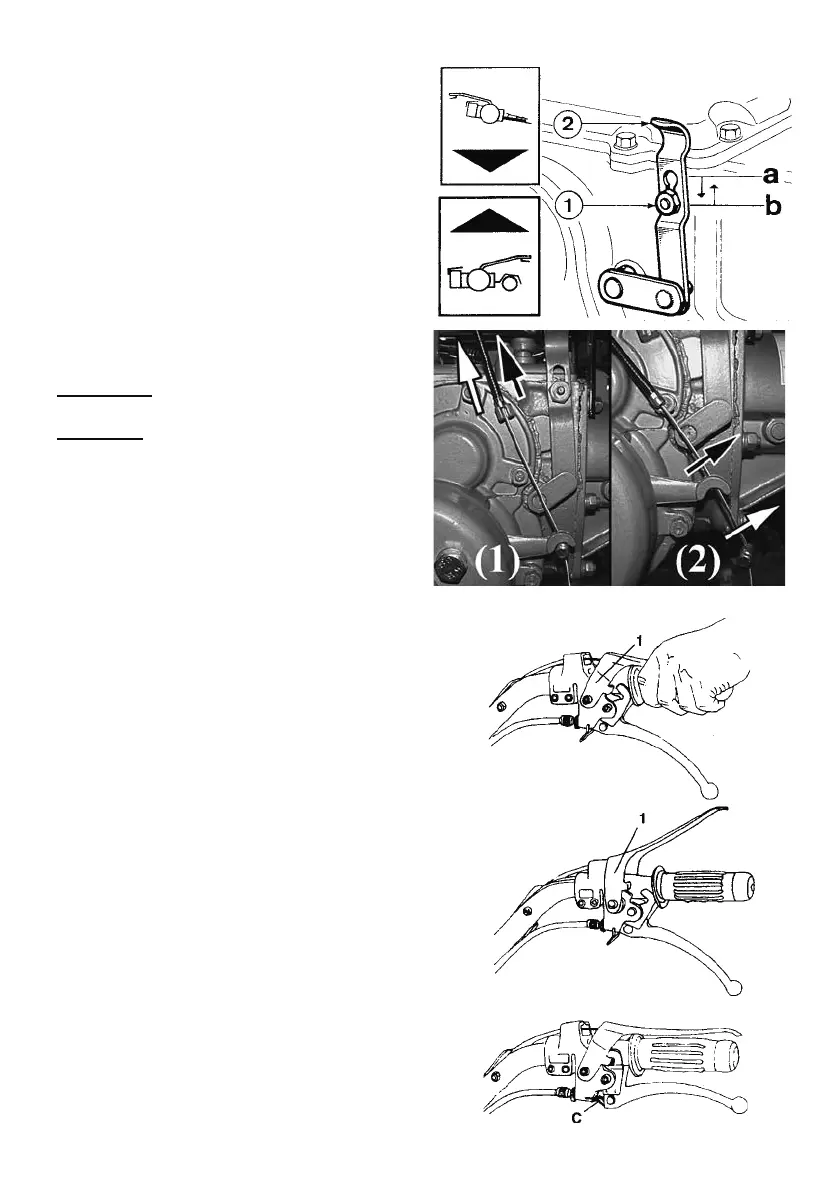

4) Pull lever 10 ( Fig. 2 ) and rota-

te the column in anti-clockwise direc-

tion (leftwards), as shown in Fig. 7/B.

5) Bring lever 10 back to its original position

to thus lock the column.

6) Put handles back on support S.

N.B. - To bring the handlebars / column back

to normal position (tilling), repeat the same

operations whilst turning the handlebars/

column in clockwise sense (rightwards) as

shown in Fig. 7/A.

IMPORTANT - each time the handlebars

are turned through 180°, always move the

Reversing Gear control lever:

Position a - Front implement version

cultivator (Fig. 8)

Position b - Rotary hoe version cultivator

(Fig. 8)

N.B. - To facilitate invertor engagement,

engage the IV gear and whilst pulling the

clutch, perform small to and fro movements

with the wheels.

Fig.8

Fig. 10

Fig. 11

Fig. 9

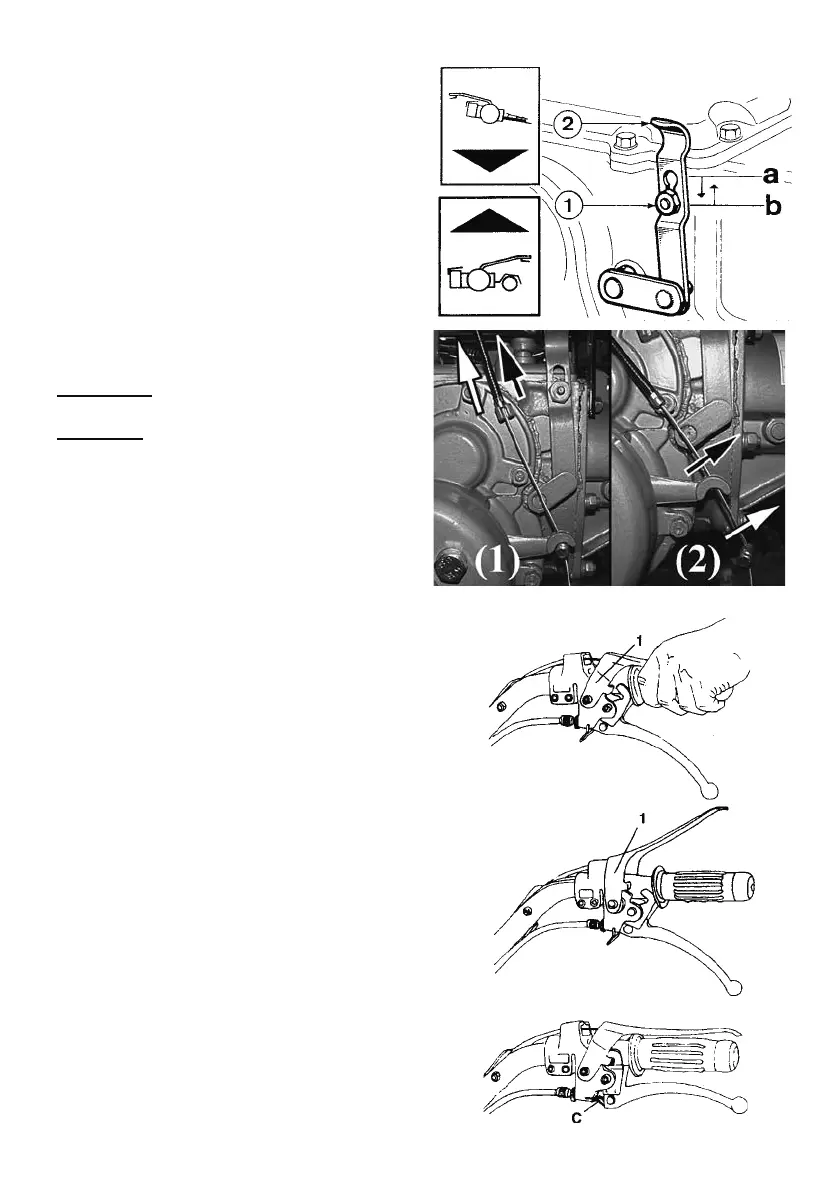

SAFETY DEVICES

The Motorcultivators are equipped with

several safety devices, which are:

1) Engine Stop “MOTORSTOP”

The working position of the Motorstop

control lever 1 is shown in Fig. 9. If, for any

reason, the handlebars are released from the

operator’s hands, lever 1 will automatically

adopt the position shown in Fig. 10 and thus

stop the engine.

2) CLUTCH HOOK

With clutch hook C (Fig 11 ) inserted, any

power transmission with gears engaged will

be prevented.

3) POWER TAKE-OFF HINDRANCE

DEVICE

The motorcultivators are equipped with a

device, fitted inside the gearbox, that controls

the engagement of the Reverse Gear and

the P.T.O. Each time the Reverse Gear is

engaged, the P.T.O. is disengaged and

vice versa.

Fig.8 A

Loading...

Loading...