50

TYRE PRESSURE

Often check that tyre pressure be within the

limits of 1-1,2 bar (Kg/cm

2

).

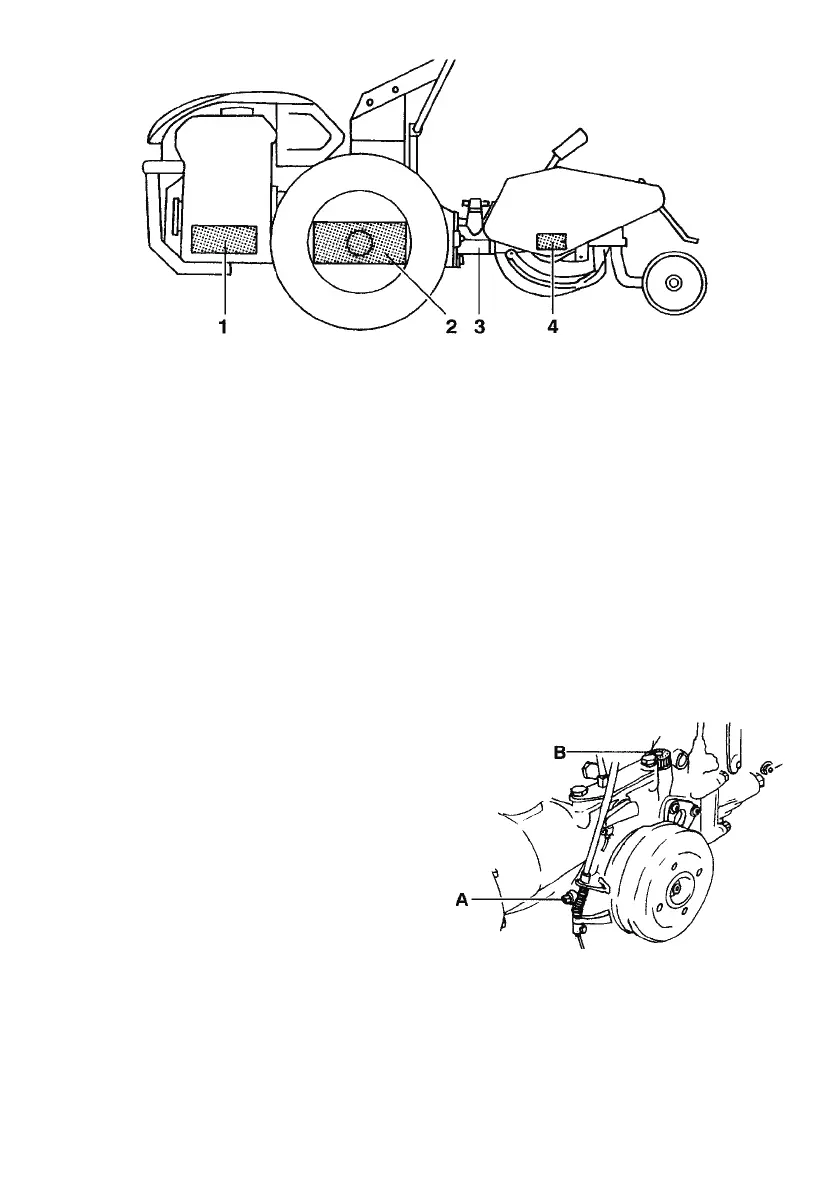

Fig.13

Fig.14

LUBRICATION (Fig. 13)

TYPE OF LUBRICANT

Engine: see engine manual.

Motorcultivator: use only ESSO UNIFARM

15-40 W oil and ESSO MULTIPURPOSE

grease.

1) ENGINE

Every day: check level and top up if ne-

cessary.

Oil replacement: to be carried out accor-

ding to intervals and methods set out by the

engine manufacturer.

2) GEARBOX (capacity 2,5 Kg)

Every 20 hours: check level and top up if

necessary.

Every 500 hours: replace oil.

3) POWER TAKE-OFF FOR IMPLEMEN-

TS

Before attaching Implements, fill up with

Multipurpose grease.

4) ROTARY HOE BOX

Capacity 0,7Kg.

Every 20 hours: check level and, if neces-

sary, top up through the clearance hole close

to screw A.

Make sure to reassemble the screw together

with aluminium washer B in order to guaran-

tee tightness.

Every 500 hours: replace oil.

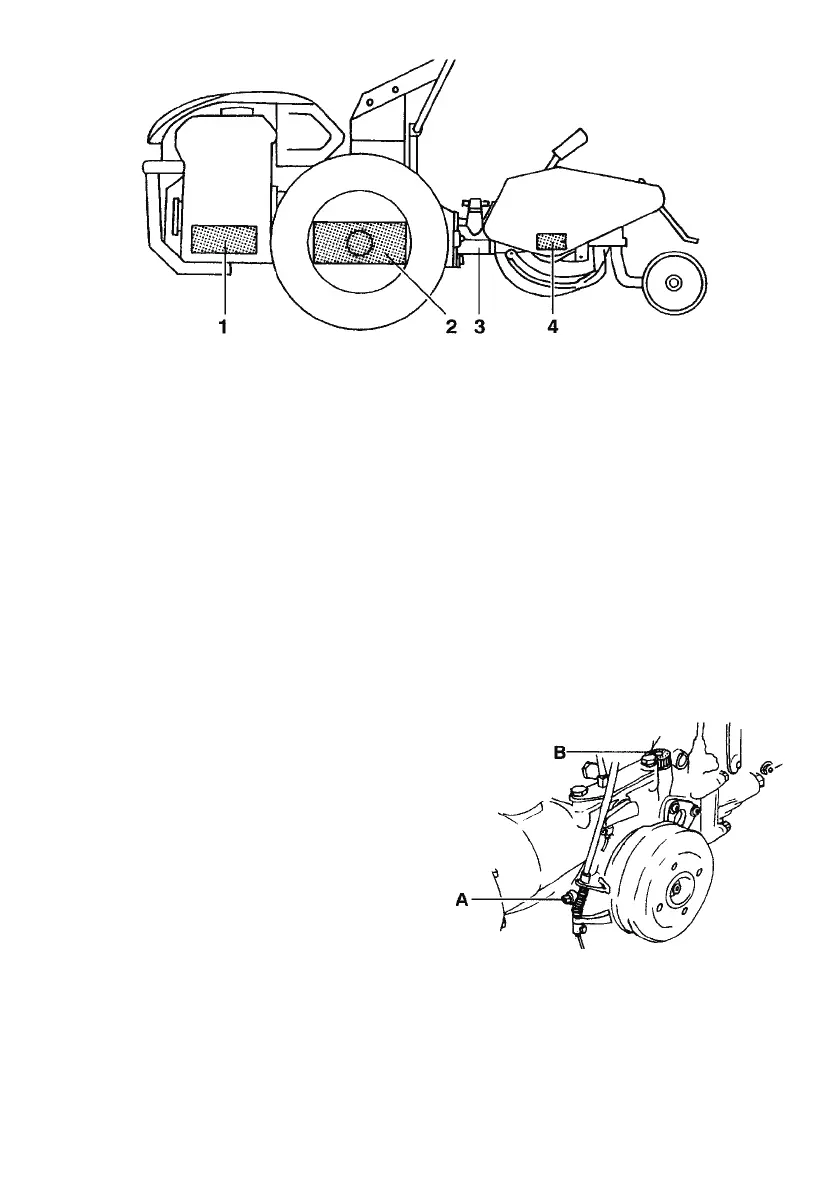

GEAR BOX OIL REPLACEMENT

(Fig. 14)

Oil must be replaced when hot, by unscrewing

fill cap A and fill cap B equipped with an oil

dipstick. When oil is completely drained,

replace cap A and pour the new oil through

hole B (2,5 Kg). Check level by using dipstick

on cap B. This operation is to be done with

motor cultivator in horizontal position.

Loading...

Loading...