15 BA-106/1EA M53.10XX

4 - Concealed hinge installation

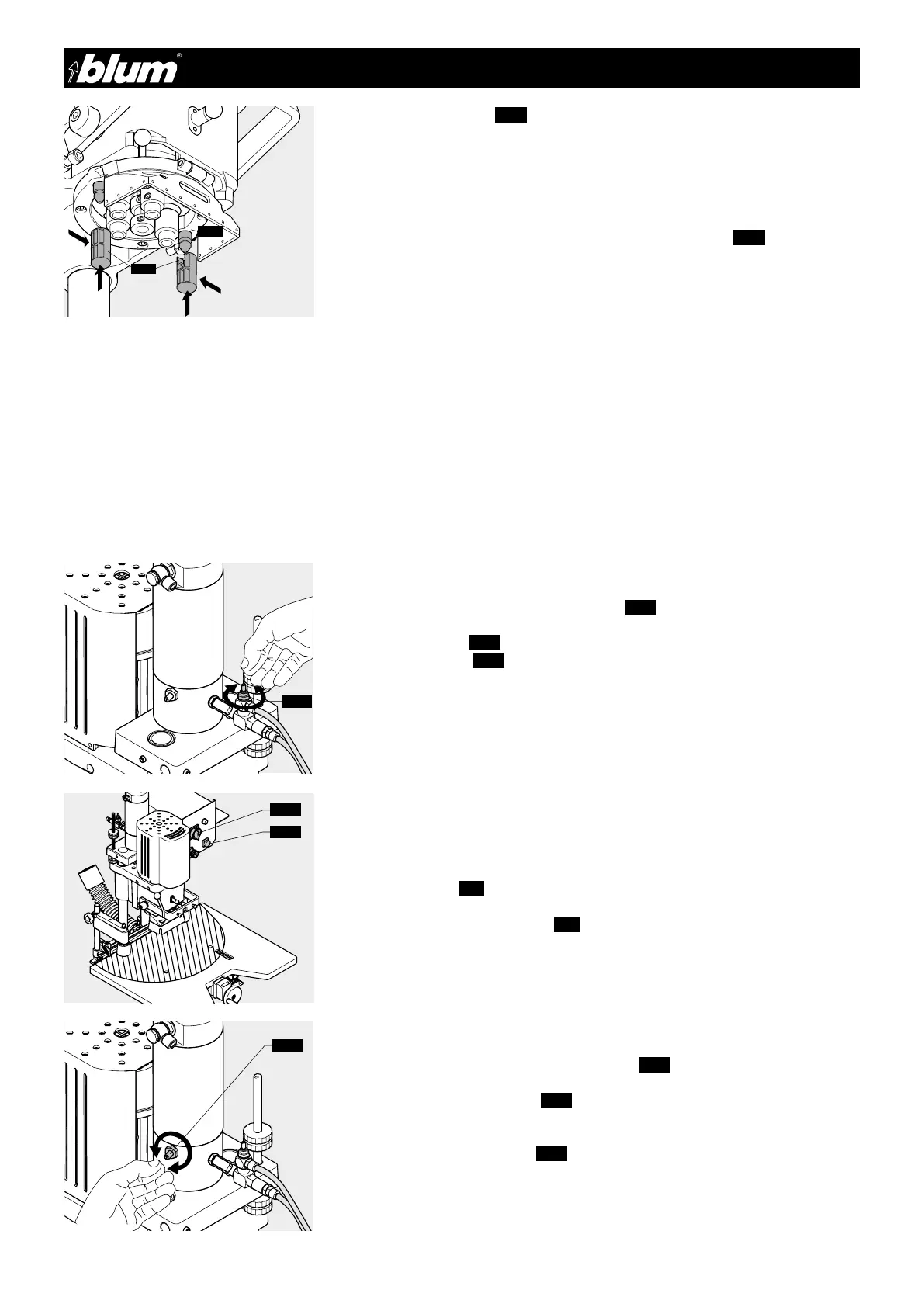

4.1.7) Boring depth stop (4.11)

Another option to maintain a constant boring depth is to install the boring depth stop.

When the boring depth stop is installed, the boring depth is always 13 mm regardless of

the thickness of the work piece.

Installing the boring depth stop:

• Drill power switch to OFF

• Remove drill bit

• Push boring depth stop into the locking holes of the retainer ring (4.12) until it

engages and turn 90 degrees with force.

• Attach drill bit

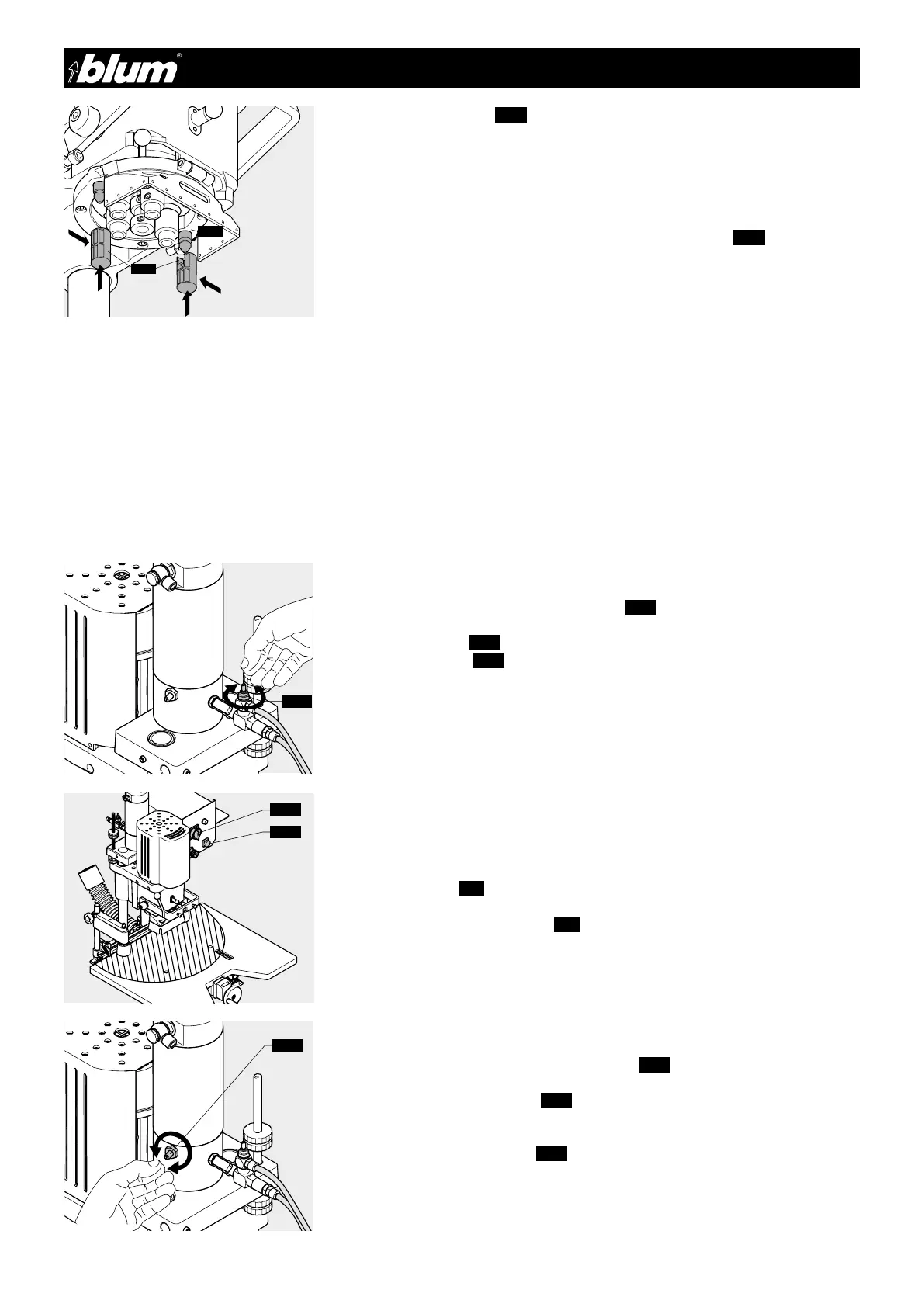

4.1.8) Setting speed of downward stroke

The stroke speed is set via a steel knurled knob (4.13) on the back of the cylinder.

• Faster: Turn screw (4.13) to the left

• Slower: Turn screw (4.13) to the right

4.1.9) Checking stroke brake

The stroke brake slows down the speed of descent just before the drill bit enters the

wood. (This extends the life of the drill bit and ensures clean edges)

• Drill power switch (3.1) to OFF

• Keep the machine’s work area (A) free.

• Press the drill/press stroke button (3.2) and observe the head movement.

4.1.10) Setting the stroke brake

The brake is set by turning the brass knurled knob (4.14) on the side of the cylinder.

• Hard wood: Turn knurled knob (4.14) to the right:

Brake will be applied harder.

• Soft wood: Turn knurled knob (4.14) to the left:

Brake will be applied less.

IMPORTANT:

The drill bit length must be set to 57 mm. (See point 4.1.2). The knurled

hand wheel should be adjusted so that it doesn

‚

t limit the boring depth.

(See point 4.1.5)

4.11

4.12

!

Loading...

Loading...