22 BA-106/1EA M53.10XX

7.1 - Maintenance

7 - Maintenance and service

• Disconnect the electrical power from the machine.

• Set power switch to OFF

• Remove (7.7 ) light bulb cover. (unscrew)

• Remove defective light bulb ( 7. 8). (Press and turn counter clockwise)

• Install new bulb (7.8). (Press and turn clockwise)

• Reattach ( 7.7) light bulb cover.

7.1.4) Releasing cylinder air pressure

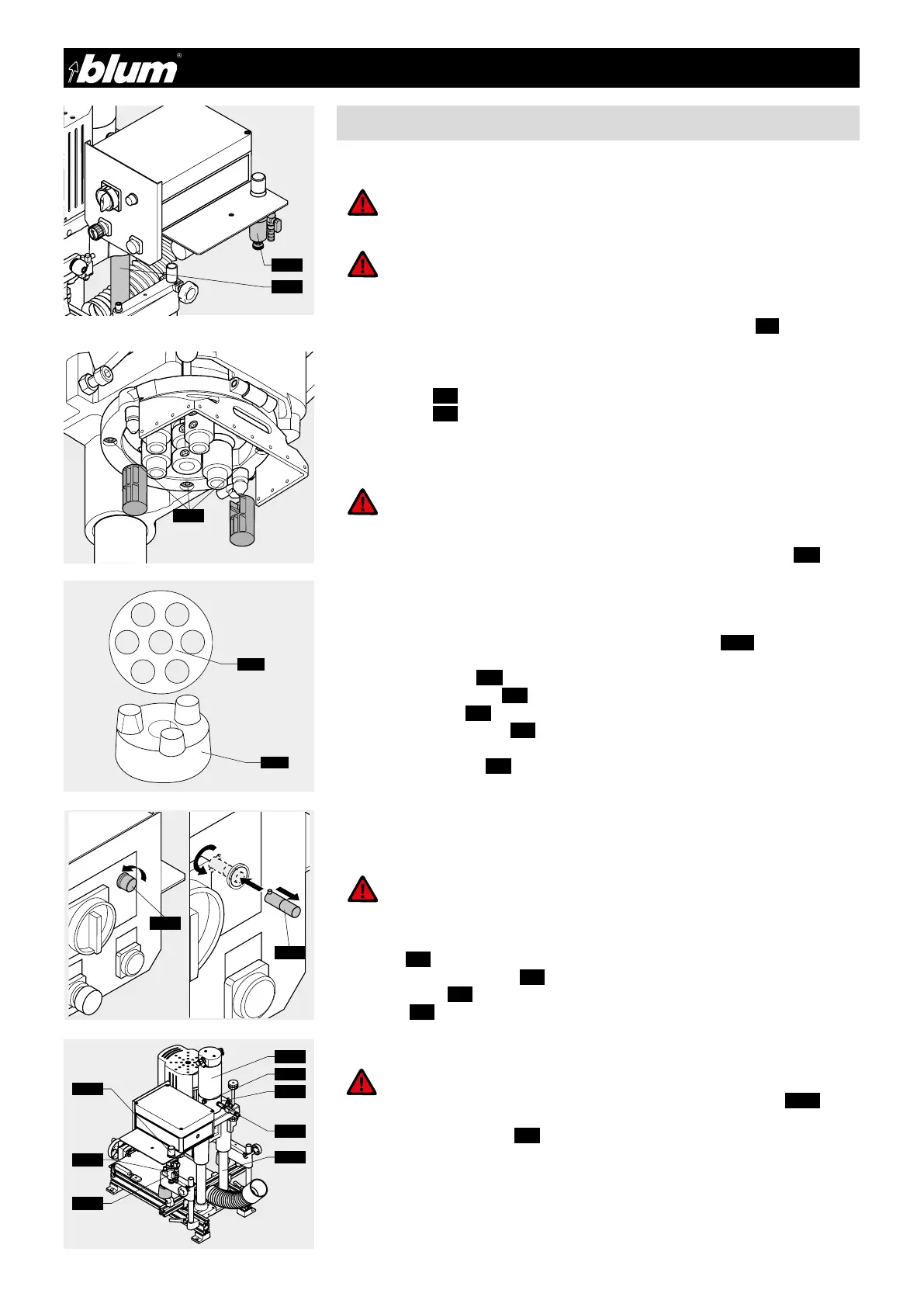

• Dust and chips should be removed from the machine on a regular basis

• Before using the machine, you should always check the air filter unit (7.1) for water

which may accumulate there. Empty the unit if necessary.

• Before every use of the machine, check the pneumatic lines and electrical lines for

damage.

• The columns ( 7. 2) are maintenance free and should not be oiled

• The columns ( 7. 2) must be cleaned regularly with a dry cloth to remove dust.

(Do not use cleaners or solvents)

ATTENTION:

Disconnect electrical and pneumatic power from machine before per-

forming any maintenance operation.

ATTENTION:

Disconnect electrical and pneumatic power from machine before per-

forming any maintenance operation.

ATTENTION:

Disconnect electrical and pneumatic power from machine before per-

forming any maintenance operation.

ATTENTION:

Air pressure remains in cylinder after pneumatic power is disconnected.

Be aware, when this action is taken the boring head will drop (4.23).Keep

hands clear.

ATTENTION:

The cylinder remains pressurized after pnematic power is disconnected

from machine. To release cylinder, see section 7.1.4 for cylinder depres-

surization instructions.

7.1.1) Maintenance

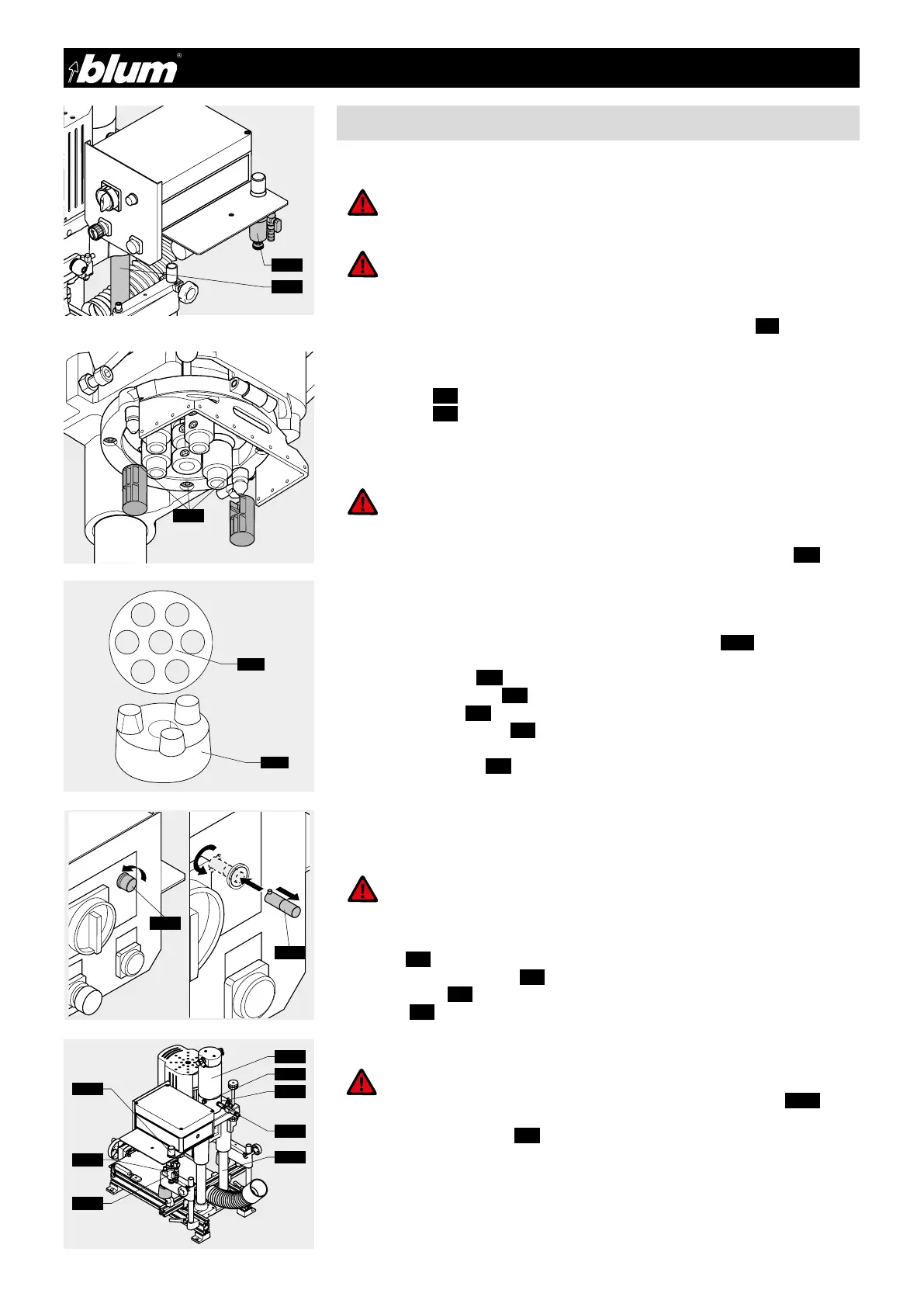

7.1.2) Damaged clutch

The clutch is damaged if:

• The drill bit is jammed in the work piece but the motor fan wheel continues (2.9)

to turn.

• Set power switch to OFF

• Disconnect electrical and pneumatic connections to the machine

• Remove drill bits

• Remove the 4 bolts that hold safety shield to gearbox housing (4.24)

• Move safety shield to one side then while holding internal gearbox, pull out boring

head securing knob. (4.5) This will allow the internal gearbox to come down and out.

• Remove dampening ring ( 7. 5)

• Remove old clutch (7.6)

• Attach replacement clutch (7.6) on to the spindle. (ensure correct positioning of clutch

and spindle)

• Insert dampening ring ( 7.5)

• Preposition clutch base for alignment with motor

• Slide gear box up into housing

• Ensure clutch reengages

• Reinstall safety shield

7.1.3) Replacing the light bulb

• Use the cylinder vent valve ( 7. 9) to release air pressure from the cylinder.

7. 6

7. 5

4.24

Loading...

Loading...