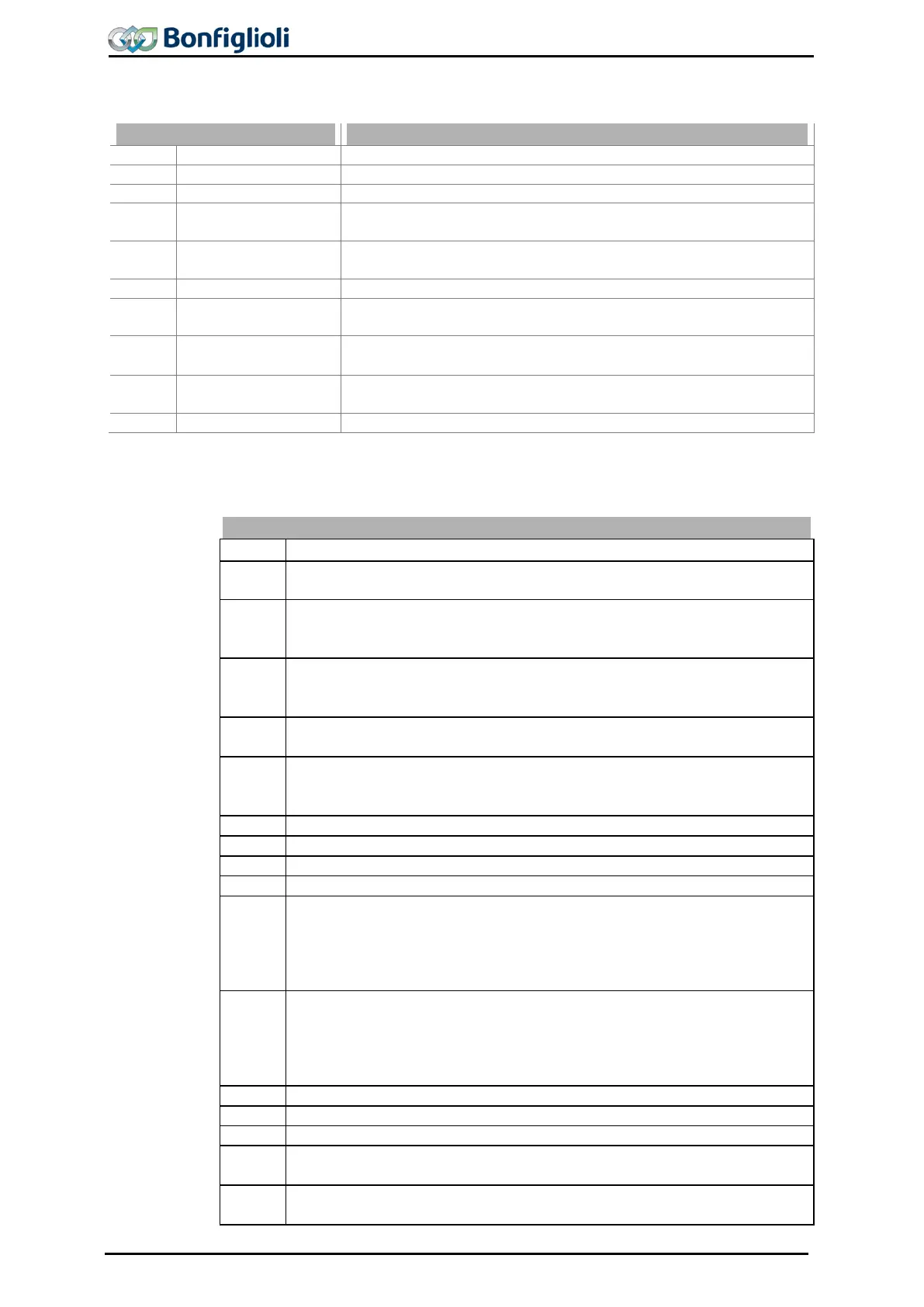

8.2.7 Status messages during commissioning (SS…)

The following status messages are possible during commissioning (setup):

Auto setup routine has been carried out.

The plausibility check (PC) of the motor data is active.

The calculation of dependent parameters is active.

The parameter identification demands enable on digital input

STOA and STOB.

Parameter identifica-

tion

The rated motor values are checked by the parameter identifica-

tion feature.

The setup routine via the operator panel is being carried out.

No enable signal. The parameter identification demands enable on

digital input STOA and STOB.

Error during the auto set-up routine. Check the value of Actual

error 259.

The parameter identification feature diagnosed an unbalance dur-

ing the measurements in the three motor phases.

The setup is not carried out until now.

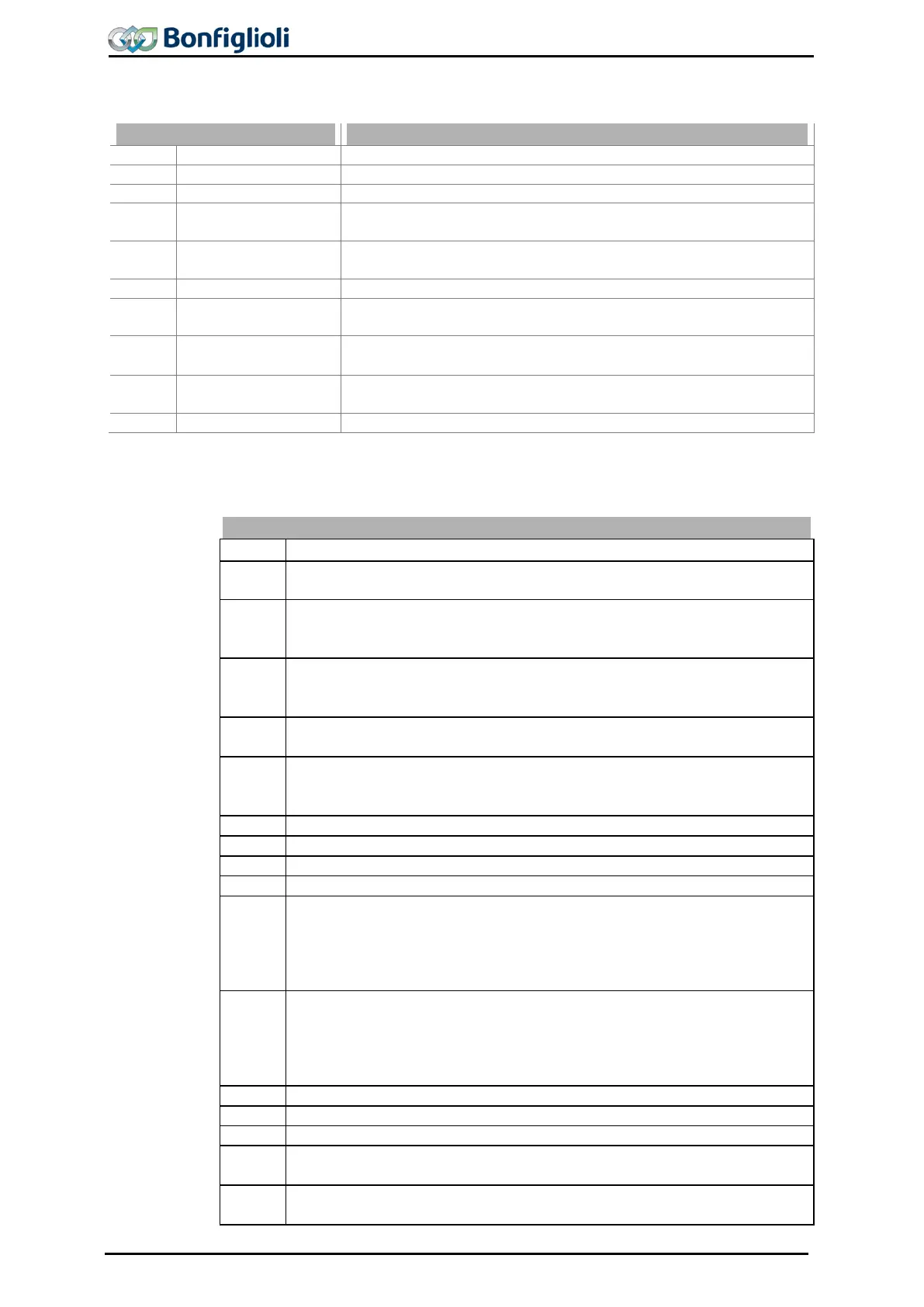

8.2.8 Warnings during commissioning (SA…)

SA000

No warning message present. This message can be read out via an option-

al communication board.

SA001

The value of the parameter Rated voltage 370 is out of the rated voltage

range of the frequency inverter. The maximum reference voltage is indi-

cated on the nameplate of the frequency inverter.

SA002

For a three-phase motor, the calculated efficiency is in the limit range.

Check the values entered for the parameters Rated voltage 370, Rated

current 371 and Rated power 376.

SA003

The value entered for parameter Rated cos phi 374 is outside of the nor-

mal range (0.6 to 0.95). Check the value.

SA004

For three-phase motor, the calculated slip is in the limit range.

Check the values entered for parameters Rated speed 372 and Rated fre-

375.

Current Controller non typical value; refer to 17.5.1.

Current Controller non typical value with 2 kHz; refer to chapter 17.5.1.

Current Controller non typical value with 4 kHz; refer to chapter 17.5.1.

Current Controller non typical value with 8 kHz; refer to chapter 17.5.1.

The stator resistance is very high. The following causes are possible:

− The motor cable cross-section is not sufficient.

− The motor cable is too long.

− The motor cable is not connected correctly.

− The contacts are not in a proper condition (corrosion).

The rotor resistance is very high. The following causes are possible:

− The motor cable cross-section is not sufficient.

− The motor cable is too long.

− The motor cable is not connected correctly.

− The contacts are not in a proper condition (corrosion).

Shorten Motor Line using Switching frequency 16 kHz.

Shorten Motor Line using Switching frequency 12 kHz and higher.

Shorten Motor Line using Switching frequency 8 kHz and higher.

The slip speed was not determined correctly. Check the values entered for

parameters

372 and

375.

The slip speed was not determined correctly. Check the values entered for

parameters Rated speed 372 and Rated frequency 375.

108 Operating Instructions ACU 06/13

Loading...

Loading...