2506/05

8.5.7 0x6049/n Velocity deceleration

The change of speed and deceleration time are set with the object velocity

deceleration. The object velocity deceleration defines the value delta speed in the

same notation (RPM) as the ob

ect tar

et velocity via subindex 1 and the value delta

time in seconds via subindex 2.

Velocity acceleration

Index Subindex Meaning Value

0x6049 0 Number of entries (unsigned 8) 2

1 Delta speed (RPM) (unsigned 32)

2 Delta time (sec) (unsigned 16)

The gradient of the frequency in deceleration is internally written onto the parameters

Deceleration (clockwise) 421 and Deceleration (anti-clockwise) 423 in the first data

set. The two parameters are set to the same value, which is specified via the ob

ec

velocity acceleration.

The gradient is internally changed by chan

in

the ob

ects delta time or delta speed.

Chan

in

the ob

ect value for delta speed, which is internally converted into the uni

Hz, is sufficient for a change of the gradient.

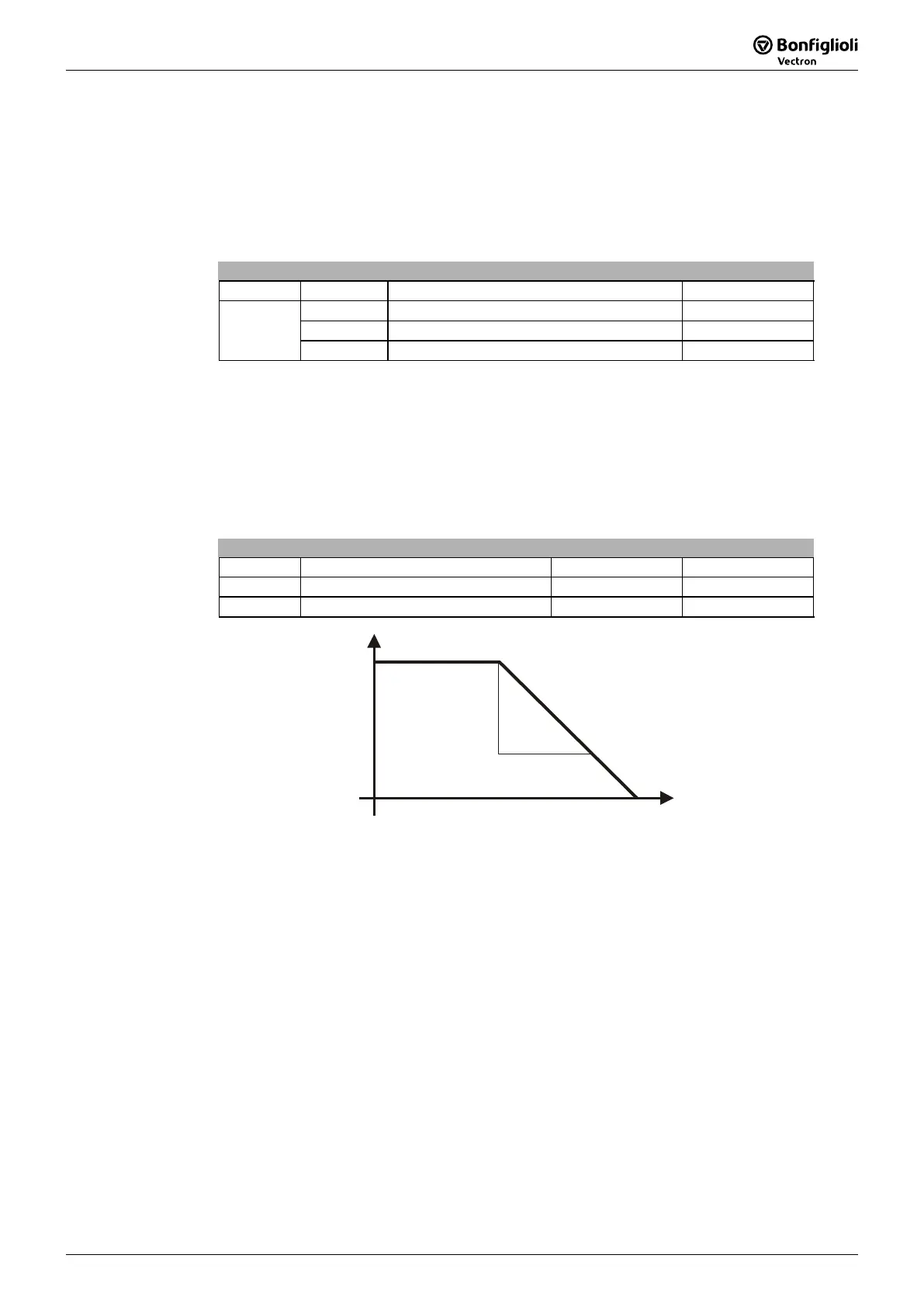

Parameter Setting

No. Object Min. Max.

0x6049/1 Delta speed (RPM) 1 65536

0x6049/2 Delta time (sec) 1 65535

delta speed

delta time

time

speed

Note:

he ob

ect delta time is always set to the ob

ect value = 1 after the rese

of the frequency inverter.

Loading...

Loading...