Aspirating Smoke Detector Planning | en 61

Bosch Sicherheitssysteme GmbH Operation Guide 2018.04 | 2.0 | F.01U.130.926

2. Option: reducing the number of air sampling openings

Reduced sensitivity at the air sampling openings can be offset by reducing the number of air

sampling openings. A distinction must be made regarding whether the cross-section of an

acceleration opening is smaller or the same as:

– the cross-section of the last air sampling opening of a branch

– the doubled cross-section of the last air sampling opening of a branch

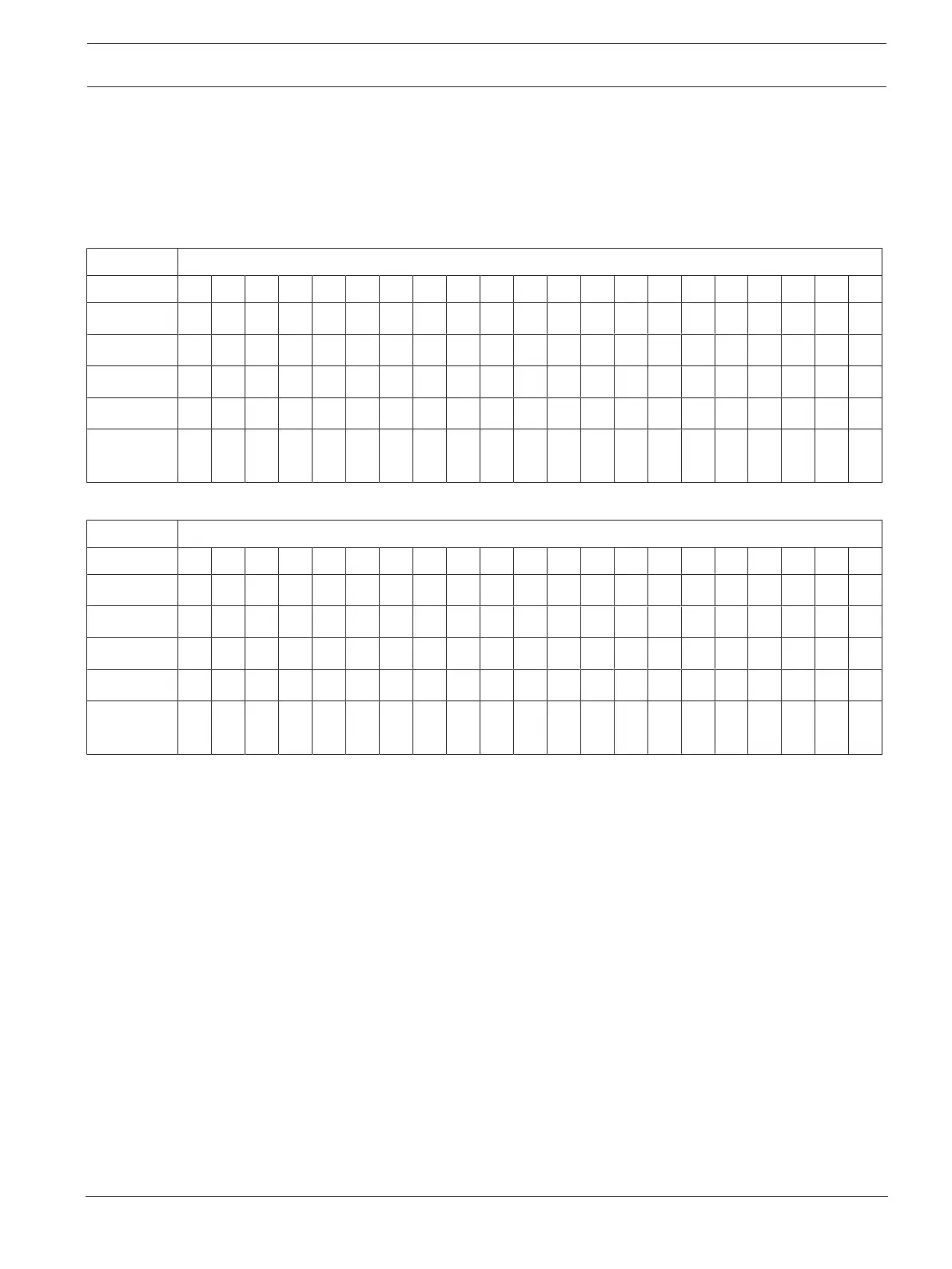

Air sampling openings

Pipe shape 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 18 20 21 24 32

I 1 2 3 4 5 6 7 8 9 10 11 12

U 2 4 6 8 10 12 14 16 18

M 3 6 9 12 15 18

Double U 4 8 12 16 20

Quadruple

U

8 16 24

Table4.4: Reducing the number of air sampling openings (acceleration opening corresponds to one air sampling opening)

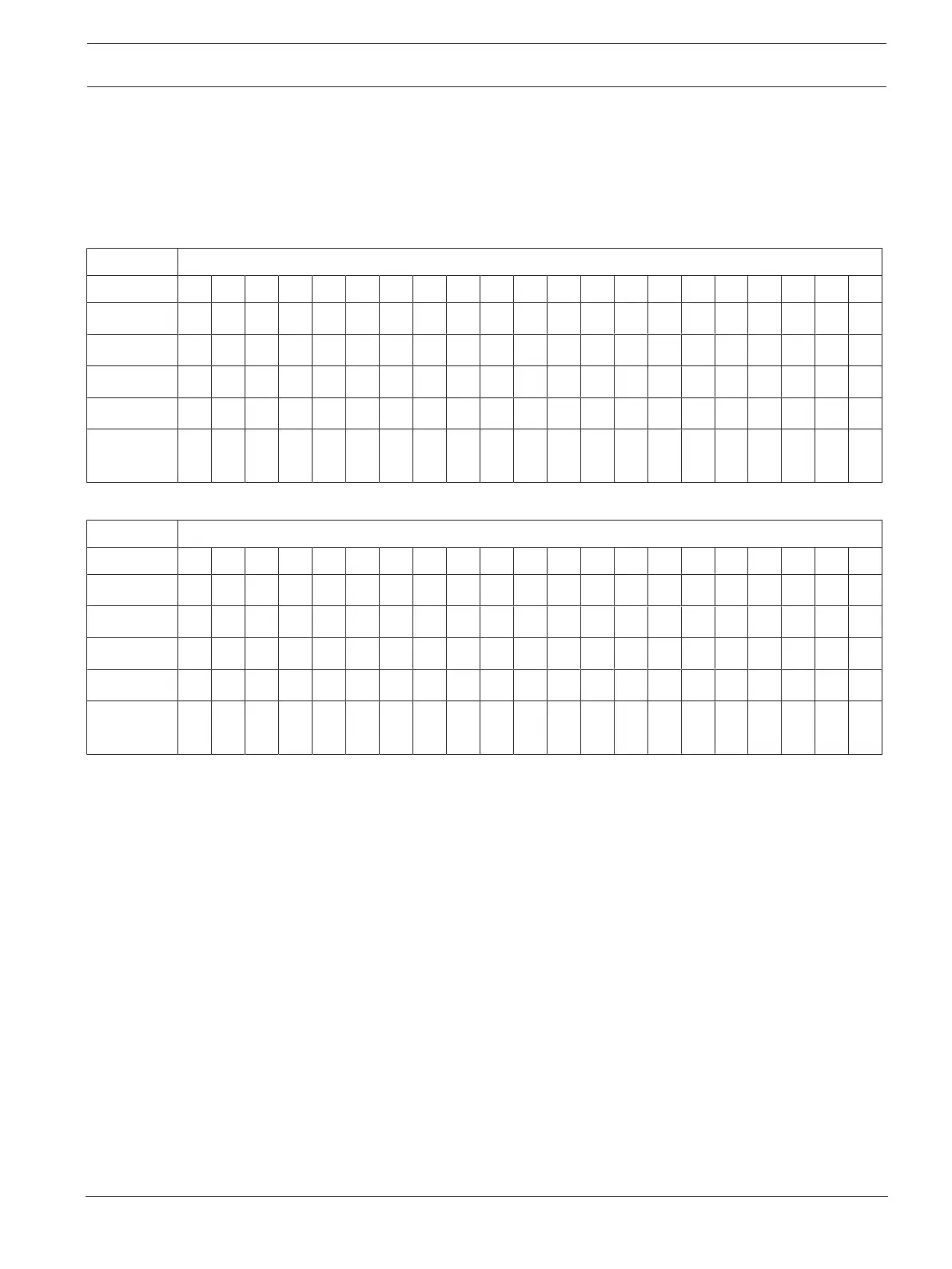

Air sampling openings

Pipe shape 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 18 20 21 24 32

I 1 1 2 3 4 5 6 7 8 9 10 11

U 2 2 4 6 8 10 12 14 16

M 3 3 6 9 12 15

Double U 4 4 8 12 16

Quadruple

U

8 8 16

Table4.5: Reducing the number of air sampling openings (acceleration opening corresponds to two air sampling openings)

Example:

A class B double U-pipe system with 24 air sampling openings is planned. According to EN

54‑20 and ISO 7240-20, 24 openings are permitted in class B at a sensitivity of 0.25% LT/m. In

order to increase the transport time, an acceleration opening twice the size as the last air

sampling opening is to be used. According to 2. Option: reducing the number of air sampling

openings, page 61, 16 air sampling openings are permitted in this case at a sensitivity of

0.25% LT/m.

It may be necessary to increase the system's transport time in order to meet individual

requirements. For this purpose, acceleration apertures can be planned at the end of the pipe

branch, which will increase the transport rate.

For the design of pipe systems with acceleration apertures, please refer to the following table

for aspiration holes and particular pipe configuration. Furthermore compliance is required

with special design tables for the design of smoke aspiration systems with acceleration

apertures

Loading...

Loading...