70 en | Planning Aspirating Smoke Detector

2018.04 | 2.0 | F.01U.130.926 Operation Guide Bosch Sicherheitssysteme GmbH

1

v

1

v

1 >

v

2 >

v

3 >

v

4

v

2

v

3

v

4

Speed distribution in an air-conditioning duct

1 Air-conditioning duct

V

1

-V

4

Flow speed

Aspiration

To achieve optimal detection results, the pipe system should be organized into the areas v

1

tov

3

Installation location of the pipe system

The exhaust duct should be selected as the installation location of the pipe system, as far as

possible away from the sound dampers, air baffles and bends. The distance from obstacles of

this kind should be at least three times the smallest duct diameter.

If it is absolutely essential to install the pipe system directly behind air baffles, sound dampers

or bends; the main speed ranges must be monitored (see Installation location of the pipe

system , page 70/Installation location of the pipe system , page 70).

Direction change of the duct without air baffles

1 Main speed range

2 Exceptional arrangement of

the pipe system (if distance

of 3xd

min

cannot be

observed)

3 Typical pipe system

arrangement

d

min

Smallest duct diameter

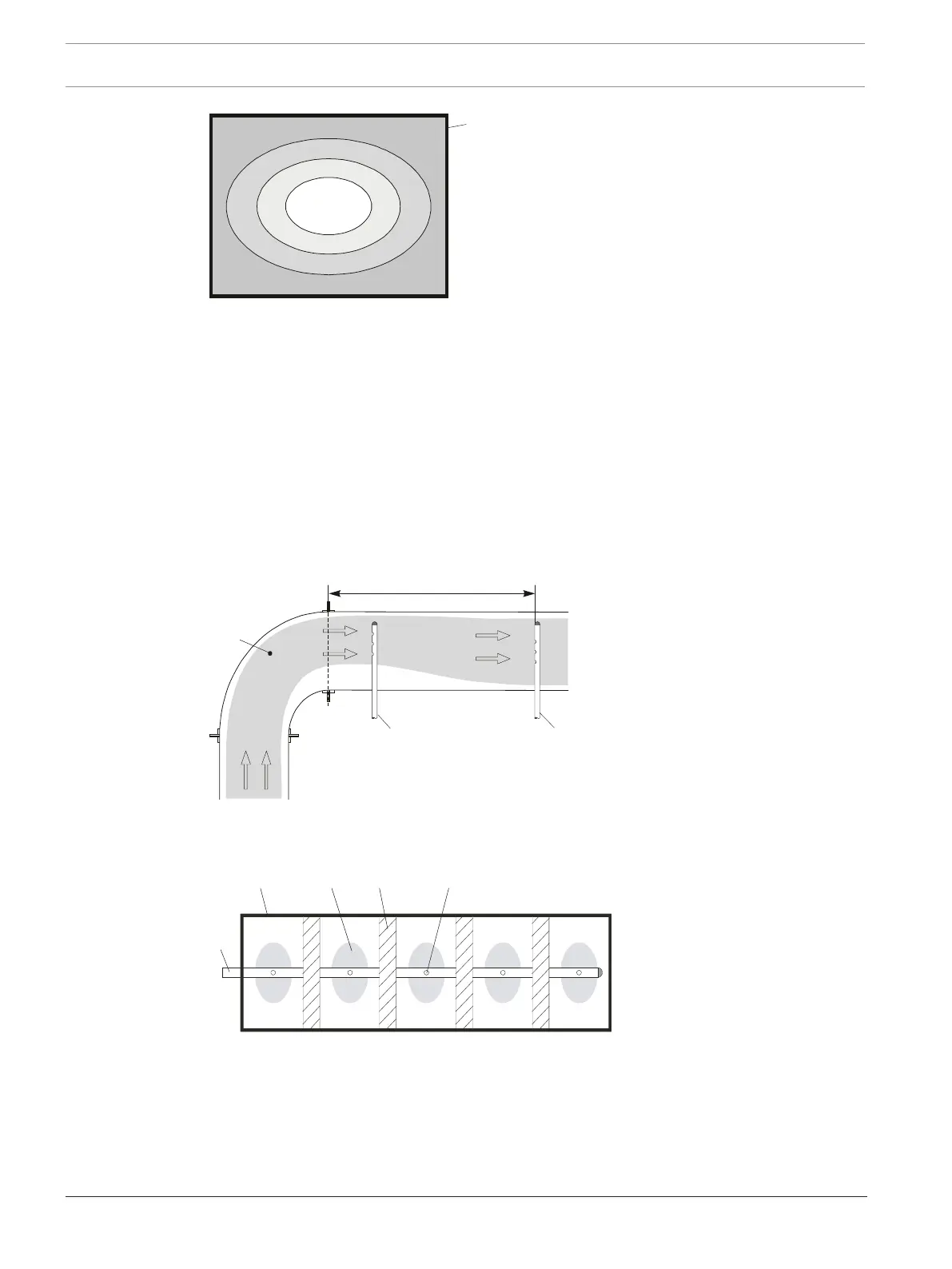

Sound dampers in a duct

1 Smoke aspiration pipe

2 Air-conditioning duct

3 Main speed range

4 Sound dampers

5 Bore

When installing a pipe system in air-conditioning ducts, the following must be observed:

– Since the FCS-320 and the pipe system are located in different pressure ranges, an air

return pipe (see Installation location of the pipe system , page 70) must be provided.

– The pipe entries into the duct must be airtight.

– The portion of the pipe system that is outside the duct must be sealed airtight.

Loading...

Loading...